A kind of laser protection material and preparation method thereof

A laser protection and product technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of rare powder materials for laser protection and few powder functional materials, so as to enhance laser protection ability and ensure personal safety , Improve the effect of laser protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

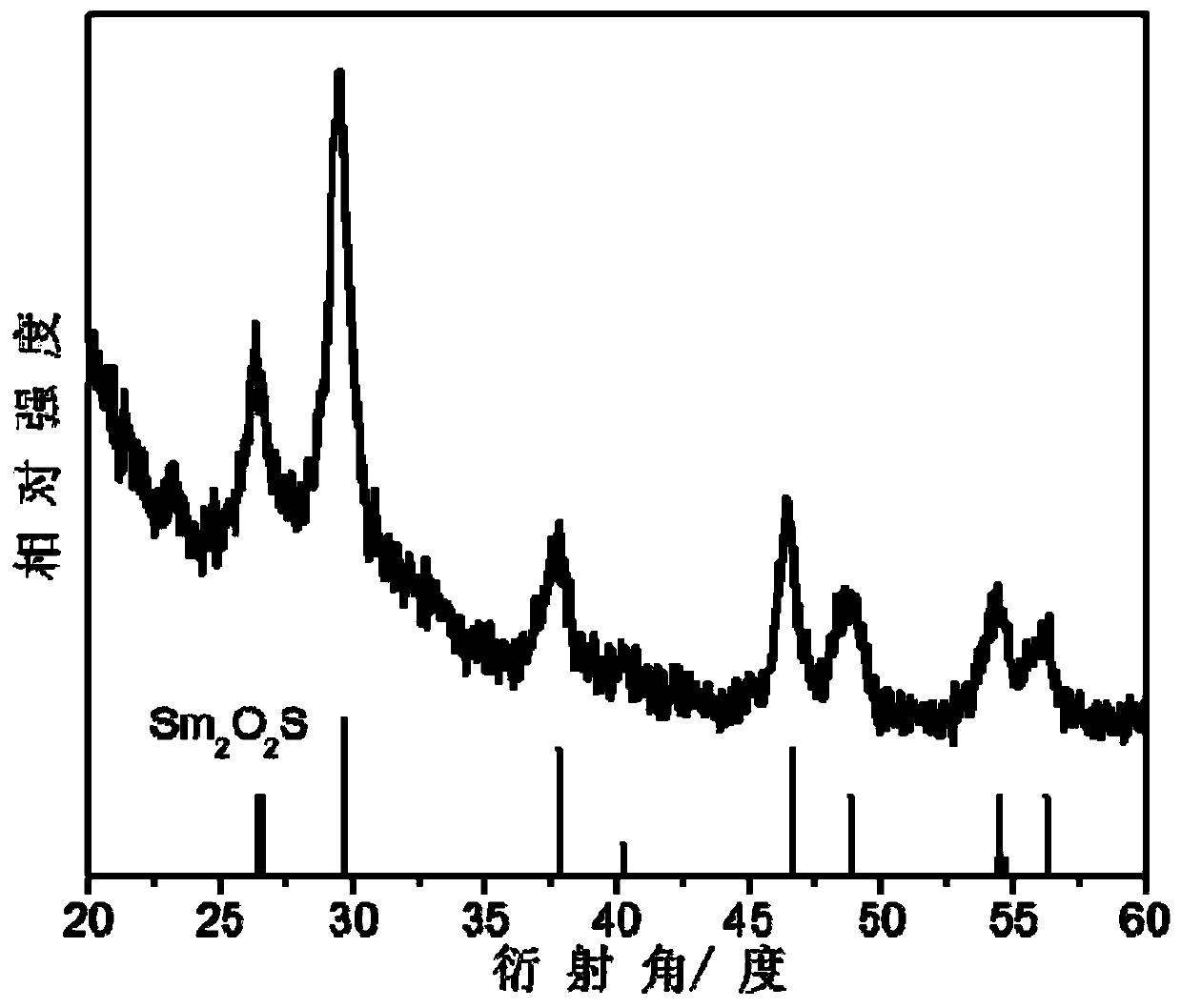

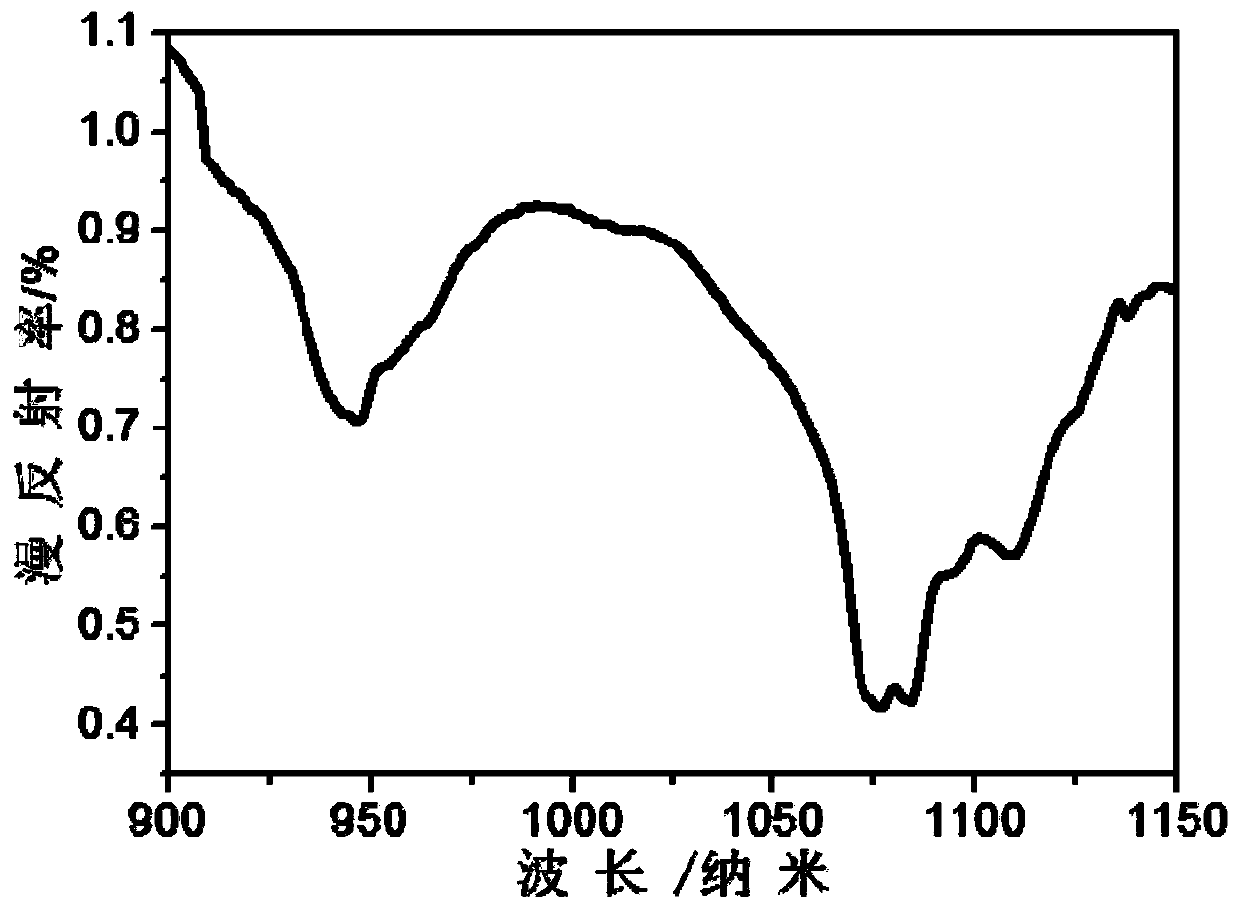

[0023] A preparation method of a laser protection material, comprising: alkaline hydrolyzing Sm, Yb and Er to obtain hydrolyzed products. Then react the hydrolyzed product in a closed and heated first environment to obtain the first product. The second product is obtained by reacting the first product with polyvinylpyrrolidone and thiourea in a closed, heated second environment.

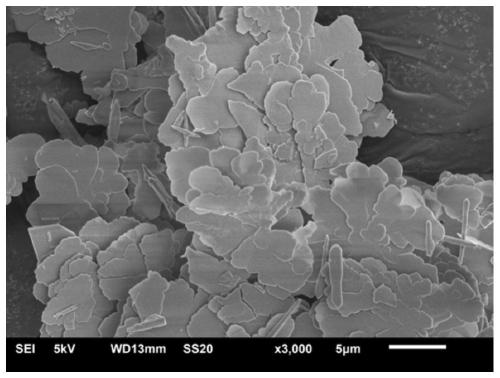

[0024] In the preparation process, no toxic sulfur-containing gas is used, but thiourea is used as a sulfur source, which ensures the personal safety of experimental operators. Thiourea also further provides a reducing environment for the synthesis of sulfur oxides. Using polyvinylpyrrolidone as a structural alignment agent to control (Sm 1-x-y Yb x Er y ) 2 o 2 The morphology of S is flake, which improves the laser protection ability of the material.

[0025] Preferably, Sm, Yb, and Er are provided in the form of one or more of nitrates and hydrates thereof, chloride salts and hydrates thereo...

Embodiment 1

[0034] Prepare 1mmol (Sm 0.915 Yb 0.08 Er 0.005 ) 2 o 2 S, weigh the required raw material 0.8134g Sm(NO 3 ) 3 ·6H 2 O, 0.0719g Yb (NO 3 ) 3 ·5H 2 O and 0.0044g Er(NO 3 ) 3 ·5H 2 O, completely dissolved in water to make a nitrate mixed solution, and stir evenly; adjust the pH value of the rare earth nitrate solution until the pH value of the rare earth nitrate solution is stable to 10; place the adjusted pH value of the rare earth nitrate solution under high pressure In the reaction kettle, react at 160°C for 32 hours, then cool down to room temperature naturally, wash the product with water three times, add absolute ethanol, and stir well; weigh 4.4g of polyvinylpyrrolidone and 0.3045g of thiourea, and dissolve them completely in the mixing solution, and stir evenly; put the evenly stirred mixed solution in a high-pressure reactor, react at 220°C for 32 hours, then cool down to room temperature naturally, and wash the reacted product 4 times with absolute ethanol;...

Embodiment 2

[0036] Prepare 1mmol (Sm 0.895 Yb 0.10 Er 0.005 ) 2 o 2 S, weigh the required raw material 0.7957g Sm(NO 3 ) 3 ·6H 2 O, 0.0898g Yb(NO 3 ) 3 ·5H 2 O and 0.0044gEr(NO 3 ) 3 ·5H 2 O, completely dissolved in water to make a nitrate mixed solution, and stir evenly; adjust the pH value of the rare earth nitrate solution until the pH value of the rare earth nitrate solution is stable to 9.8; place the adjusted pH value of the rare earth nitrate solution under high pressure In the reaction kettle, react at 170°C for 29 hours, then cool down to room temperature naturally, wash the product with water 4 times, add absolute ethanol, and stir well; weigh 4.3g of polyvinylpyrrolidone and 0.3425g of thiourea, completely dissolve in the mixing solution, stirred evenly; put the evenly stirred mixed solution in a high-pressure reactor, and reacted at 210°C for 30 hours, then cooled down to room temperature naturally, and the reacted product was washed 5 times with absolute ethanol; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com