A kind of polyvinyl butyral resin-based laser protective coating and preparation method thereof

A polyvinyl butyral resin, laser protection technology, applied in coatings, devices for coating liquids on surfaces, etc. and other problems, to achieve the effect of enhancing laser protection ability, high impact strength and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

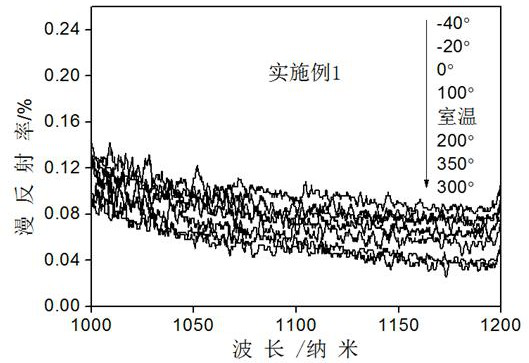

Embodiment 1

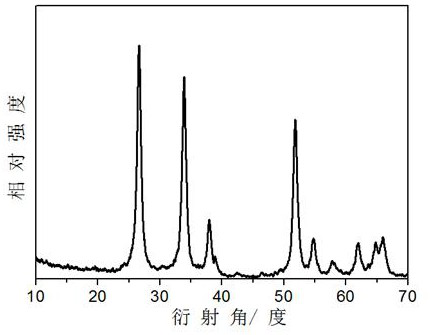

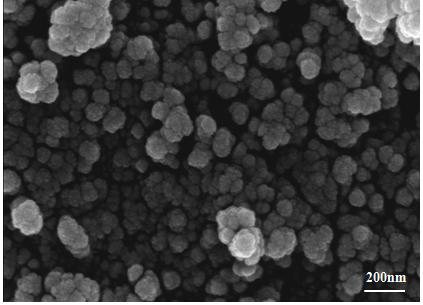

[0032] A kind of polyvinyl butyral resin-based laser protection coating, the matrix of this coating is polyvinyl butyral resin, and filler is (Sn 0.88 Sb 0.1 Er 0.02 )O 2 , the mass ratio of the filler to the matrix is 1.5, the filler (Sn 0.88 Sb 0.1 Er 0.02 )O 2 Prepared by co-precipitation method, comprising the following steps:

[0033] (1) Weigh 20.299g of SnCl according to the stoichiometric ratio 4 ·5H 2 O, 1.501gSbCl 3 , 0.502gErCl 3 ·6H 2 O is placed in a beaker, and 400mL of hydrochloric acid solution with a volume concentration of 50% is added, and the stirring is continued to completely dissolve the raw materials to form a transparent solution;

[0034] (2) Add the mixed solution of ammonia water and ammonium bicarbonate with a volume concentration of 30% to the solution prepared in step (1) dropwise, and stir until the pH value of the solution is stable at 2;

[0035] (3) After the reaction, age for 6 hours, wash with deionized water and ethanol for s...

Embodiment 2

[0043] A kind of polyvinyl butyral resin-based laser protection coating, the matrix of this coating is polyvinyl butyral resin, and filler is (Sn 0.842 Sb 0.14 Er 0.018 )O 2 , the mass ratio of the filler to the matrix is 1.6, the filler (Sn 0.842 Sb 0.14 Er 0.018 )O 2 Prepared by co-precipitation method, comprising the following steps:

[0044] (1) Weigh 19.419g SnCl according to the stoichiometric ratio 4 ·5H 2 O, 2.101gSbCl 3 , 0.452gErCl 3 ·6H 2 O is placed in a beaker, adding 430mL of hydrochloric acid solution with a volume concentration of 52%, stirring constantly, so that the raw materials are completely dissolved to form a transparent solution;

[0045] (2) Add the mixed solution of ammonia water and ammonium bicarbonate with a volume concentration of 26% to the solution prepared in step (1) dropwise, and stir until the pH value of the solution is stable at 3;

[0046] (3) After the reaction, age for 8 hours, wash with deionized water and ethanol several...

Embodiment 3

[0054] A kind of polyvinyl butyral resin-based laser protection coating, the matrix of this coating is polyvinyl butyral resin, and filler is (Sn 0.806 Sb 0.18 Er 0.014 )O 2 , the mass ratio of the filler to the matrix is 1.8, the filler (Sn 0.806 Sb 0.18 Er 0.014 )O 2 Prepared by co-precipitation method, comprising the following steps:

[0055] (1) Weigh 18.597g SnCl according to the stoichiometric ratio 4 ·5H 2 O, 2.703gSbCl 3 , 0.352gErCl 3 ·6H 2 O is placed in a beaker, add 460mL of hydrochloric acid solution with a volume concentration of 56%, and keep stirring to completely dissolve the raw materials to form a transparent solution;

[0056] (2) Add the mixed solution of ammonia water and ammonium bicarbonate with a volume concentration of 22% to the solution prepared in step (1) dropwise, and stir until the pH value of the solution is stable at 3.5;

[0057] (3) After the reaction, age for 9 hours, wash with deionized water and ethanol for several times, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com