Oil pump

An oil pump and oil cavity technology, applied in the field of automotive engineering, can solve the problems of low reliability of liquid level sensing and low accuracy of oil measurement, and achieve the improvement of the reliability of liquid level signal collection, the improvement of the ability to resist liquid level fluctuation, and the improvement of detection accuracy. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

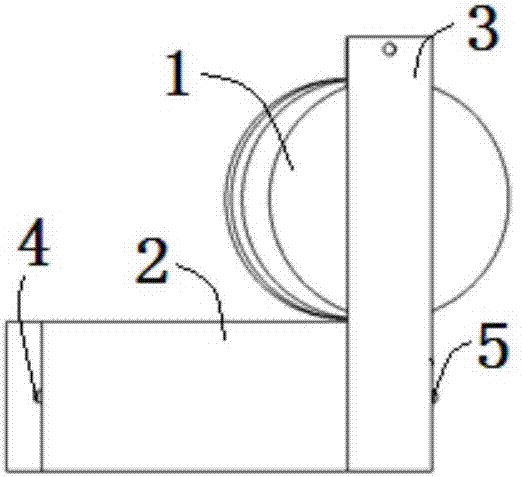

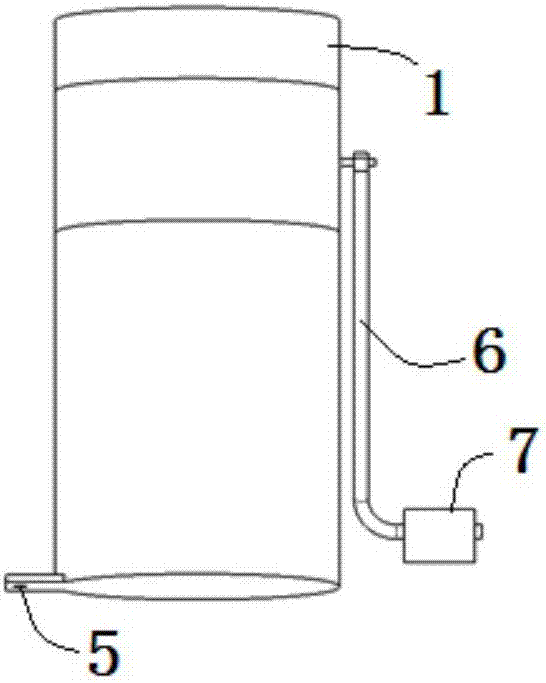

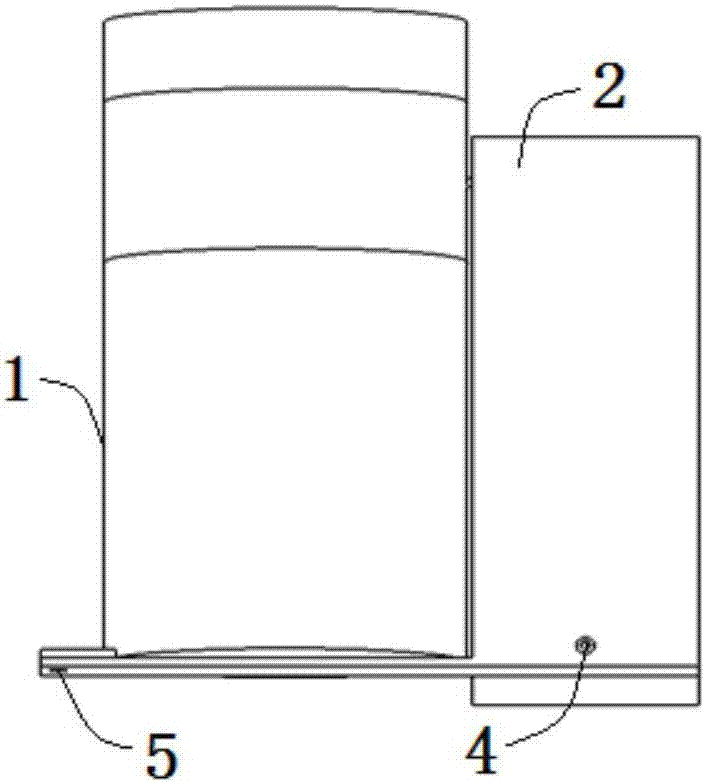

[0023] The embodiment of the present application provides an oil pump to solve the technical problems of low reliability of liquid level sensing and low accuracy of oil quantity measurement caused by the liquid level sensor in the automobile oil pump in the prior art; the anti-vibration ability is improved , the technical effect of oil quantity measurement accuracy.

[0024] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present application, the embodiments of the present application and the technical features in the embodiments can be combined without conflict.

[0025] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com