Industrial control virtual reality type teaching practical-training platform and operation method thereof

A technology of virtual reality and industrial control, which is applied in the direction of simulators, educational tools, and simulation devices for space navigation conditions. It can solve problems such as personal injury equipment, operational errors, and damage, and achieve the effect of improving safety and integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

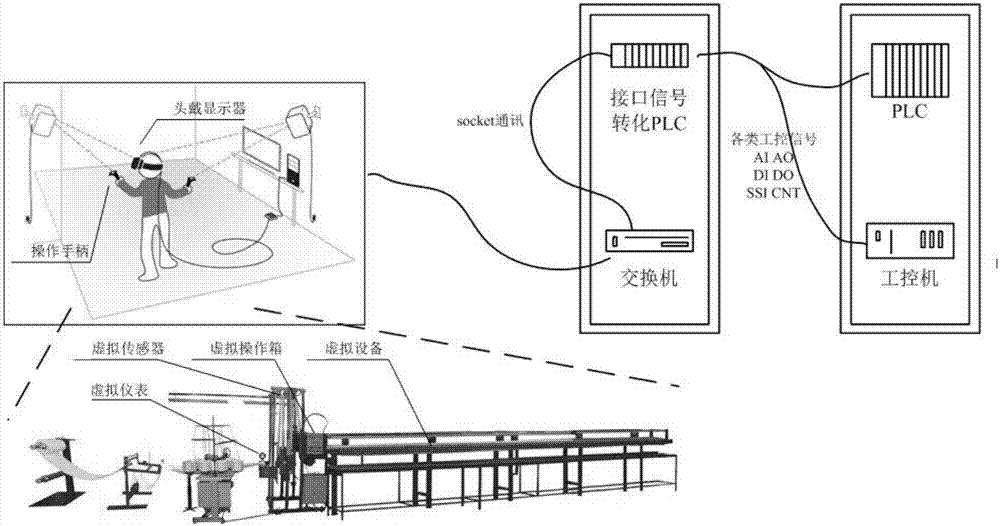

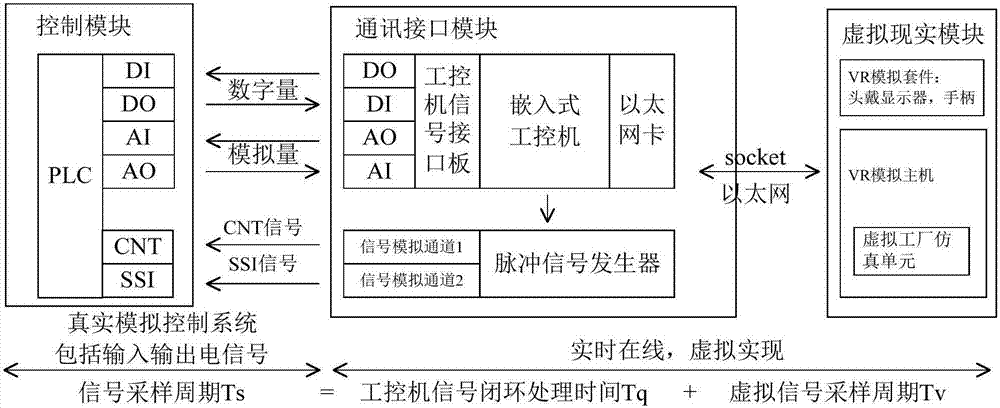

[0063] One of the core ideas of the present invention to solve the background technical problems is: the virtual reality module communicates with the control module in real time. After the relevant personnel compile the program in the control module, the real electrical signal output by the control module is converted into a virtual control signal by the communication interface module and transmitted in real time. To the virtual reality module, the virtual reality module controls the real-time operation of the production line according to the virtual control signal. At this time, the relevant personnel can observe the real scene in the virtual reality environment and verify whether the equipment operates according to the program. The virtual sensor and the virtual reality system send the virtual feedback signal to the communication interface module, and the communication interface module converts the virtual feedback signal into a real feedback signal and sends it to the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com