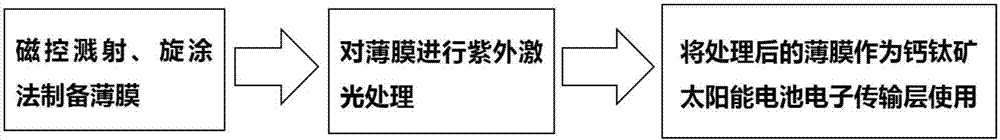

Method for processing electron transmission layer in perovskite solar cell via ultraviolet laser

A technology for solar cells and electron transport layers, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as increasing the cost of battery preparation, and achieve the advantages of avoiding high-temperature preparation, increasing open-circuit voltage and short-circuit current density, and increasing transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) ultrasonically clean the FTO glass substrate in acetone, absolute ethanol, and deionized water successively, and dry it for later use;

[0025] (2) GZO film was prepared by magnetron sputtering. The distance between the substrate and the GZO target (Ga-doped atomic percentage is 5%) was 6 cm. During the working process, the mechanical pump was used in turn, and the molecular pump vacuumed the cavity to 4×10 -4 Pa, followed by argon gas with a gas flow rate of 40 ml / min. After 10 minutes, the working pressure was adjusted to 0.6 Pa. After 10 minutes of pre-sputtering, a thin film was deposited on the substrate, and the deposition time was 3 minutes. After the deposition is completed, take it out, the thickness of the film is about 36 nanometers, and store it in a vacuum drying oven;

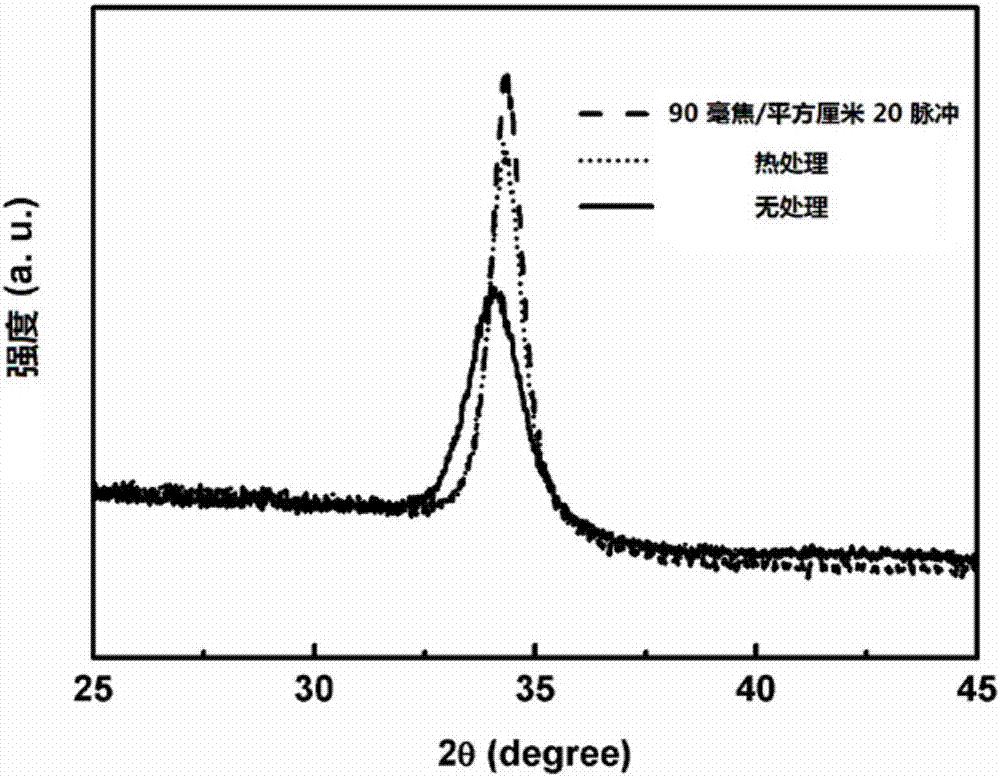

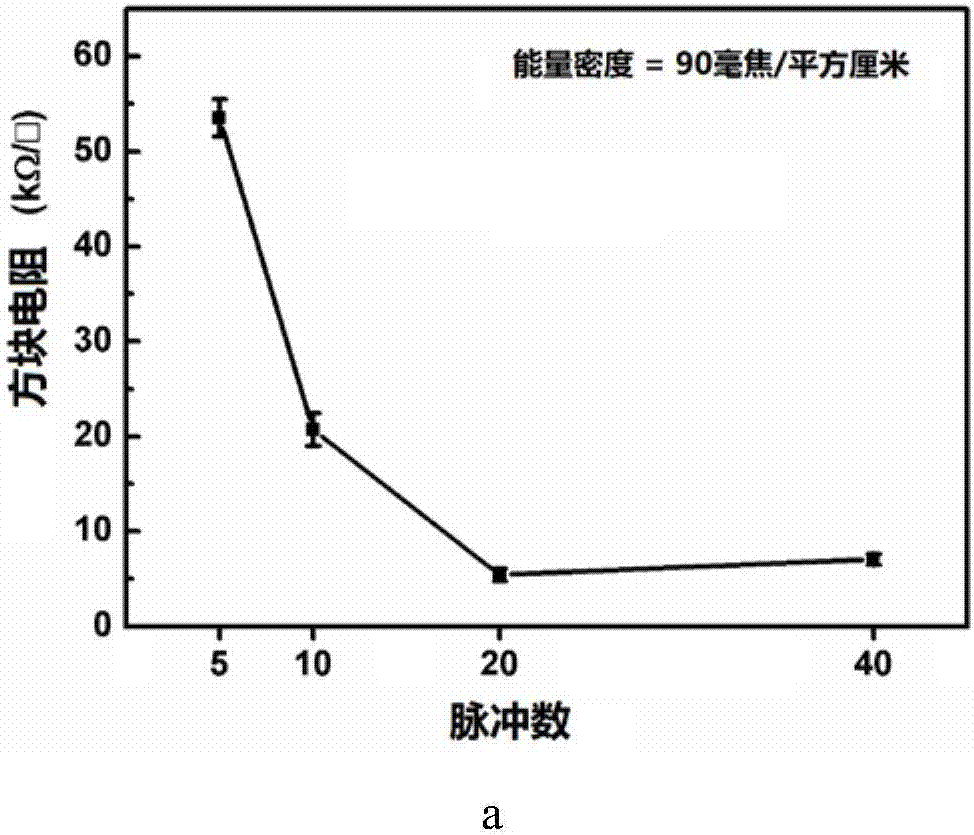

[0026] (3) A 308nm XeCl ultraviolet laser is used to process the film, the radiated laser energy is 200 millijoules, the energy density of the GZO film is 60, 75, 90, 105 millijoules p...

Embodiment 2

[0029] (1) ultrasonically clean the FTO glass substrate in acetone, absolute ethanol, and deionized water successively, and dry it for later use;

[0030](2) AZO film is prepared by magnetron sputtering. The distance between the substrate and the GZO target (Al doping atomic percentage is 5%) is 6 cm. During the working process, the mechanical pump is used in turn, and the molecular pump vacuums the cavity to 5×10 -4 Pa, followed by argon gas with a gas flow rate of 3 ml / min. After 10 minutes, the working pressure was adjusted to 0.4 Pa. After 10 minutes of pre-sputtering, a thin film was deposited on the substrate, and the deposition time was 3 minutes. After the deposition is completed, take it out, the thickness of the film is about 45 nanometers, and store it in a vacuum oven;

[0031] (3) A 308nm XeCl ultraviolet laser is used to process the film, the radiated laser energy is 200 millijoules, the energy density of the GZO film is 60, 75, 90, 105 millijoules per square ce...

Embodiment 3

[0033] (1) ultrasonically clean the FTO glass substrate and the PEN flexible substrate in acetone, absolute ethanol, and deionized water in sequence, and dry them for later use;

[0034] (2) Add 1.772 g of zinc acetate into 20 ml of ethylene glycol methyl ether, stir until completely dissolved, then slowly add 0.486 ml of ethanolamine dropwise, stir for 1 hour, filter through a 0.22 micron filter, and place a stopper In test tubes, aged for 48 hours. Add 100 microliters of colloidal solution onto the substrate dropwise, spin-coat in the glove box at 3000 rpm, spin-coat for 45 seconds, and then heat at 150 degrees Celsius for 1 hour. This process is repeated 3 times to obtain a ZnO film with a film thickness of About 90 nanometers;

[0035] (3) A 248nm laser was used to process the ZnO thin film, and the energy densities of the treatment were 100 mJ / cm2, 150 mJ / cm2, and 200 mJ / cm2. The pulse numbers were 1, 5, 10, and 20, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap