Anti-blocking loosening machine of automobile sound isolation cotton

A technology of sound-proof cotton and opening machine, which is applied to fiber opening and cleaning machines, opening and cleaning with toothed tools, etc., which can solve the problems of fiber easy to block the conveying device, and achieve the effect of simple and fast operation and low cost of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

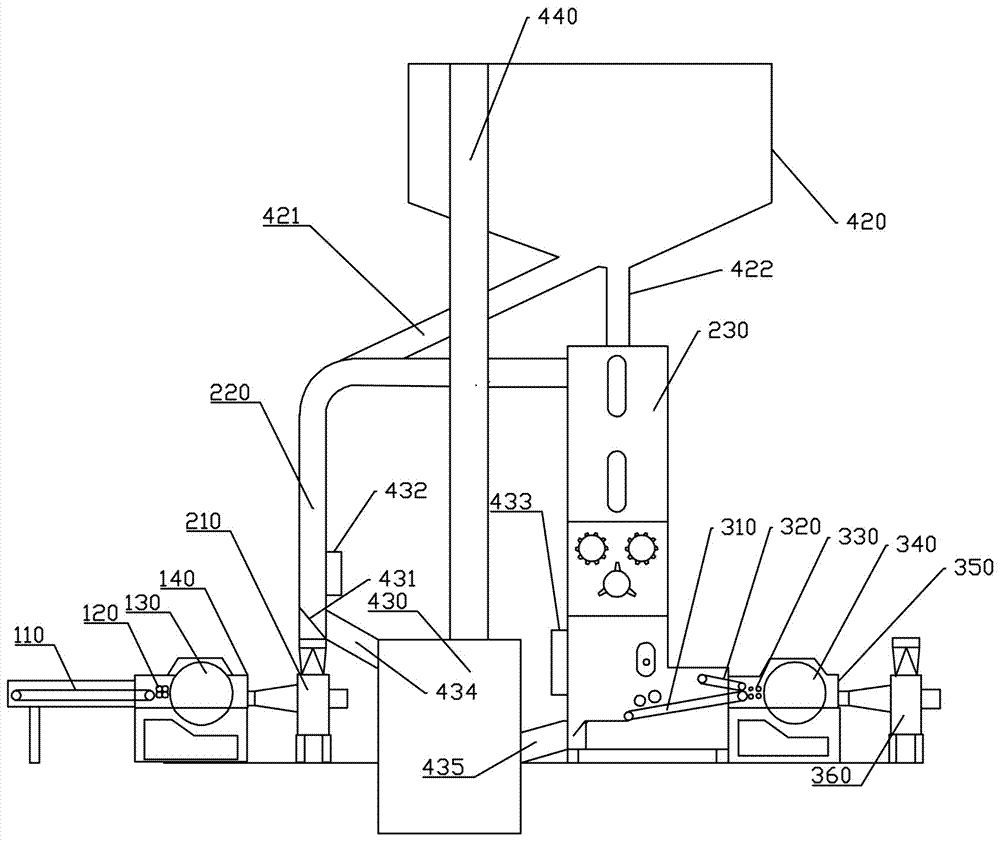

[0020] The reference signs in the accompanying drawings of the description include: conveyor belt 110, double feed roller 120, opening cylinder 130, front housing 140, inclined bottom conveyor belt 320, inclined top conveyor belt 310, rear feeding roller 330, opening Rear cylinder 340, rear housing 350, rear conveying fan 360, front conveying fan 210, feeding box 230, conveying pipeline 220, ball storage part 420, front discharge pipe 421, rear discharge pipe 422, recovery part 430, Recovery rod 431 , front recovery magnetic plate 432 , rear recovery magnetic plate 433 , front recovery pipe 434 , rear recovery pipe 435 , hoist 440 .

[0021] Such as figure 1 The anti-block opening machine for automobile sound insulation cotton includes a front opening mechanism, a fiber conveying mechanism and a rear opening mechanism. The fiber conveying mechanism connects the front ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com