A device and method for integrally assembling iron towers of overhead transmission lines

A technology for overhead transmission lines and iron towers, applied to towers, building types, buildings, etc., can solve the problems of reducing high-altitude operations and not taking into account construction efficiency at the same time, and achieve the effects of reducing high-altitude operations, improving construction quality, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

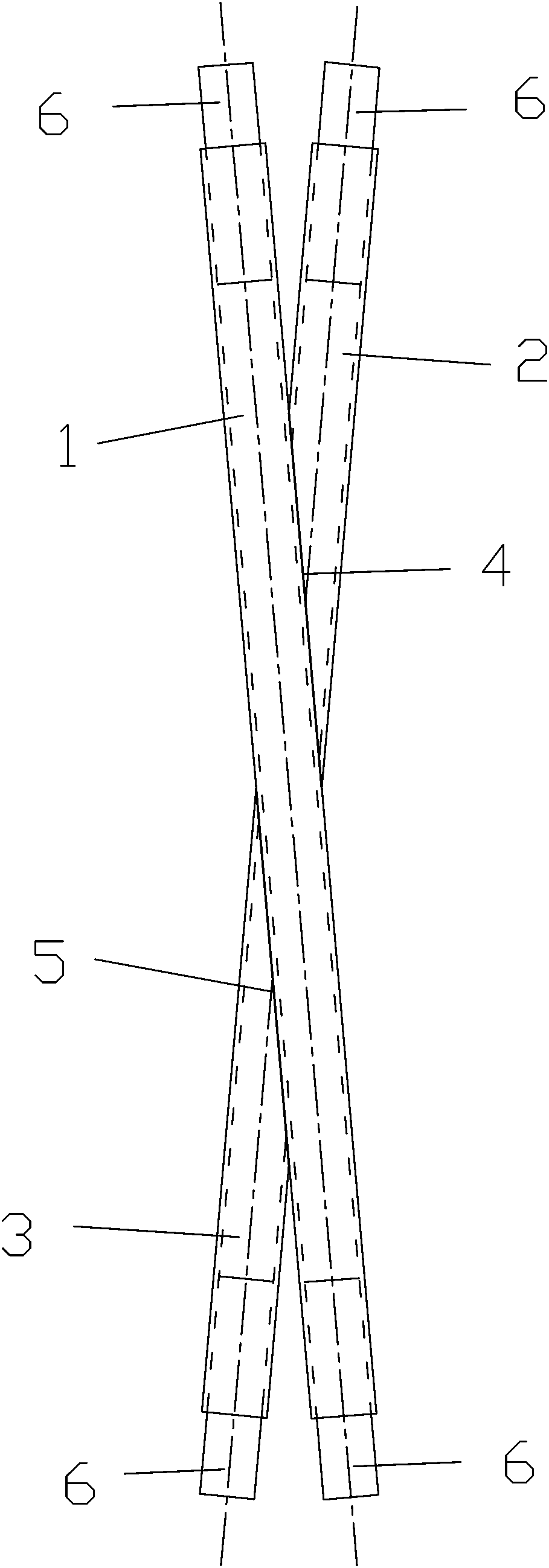

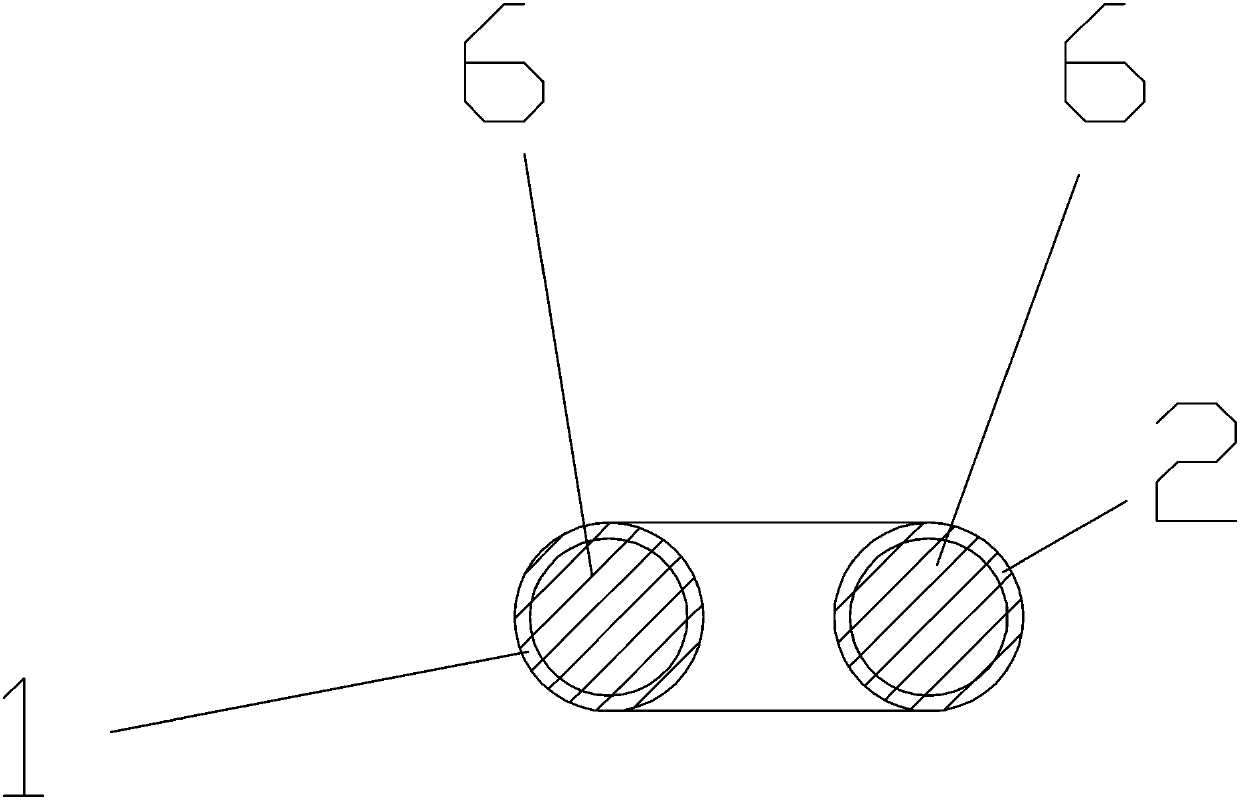

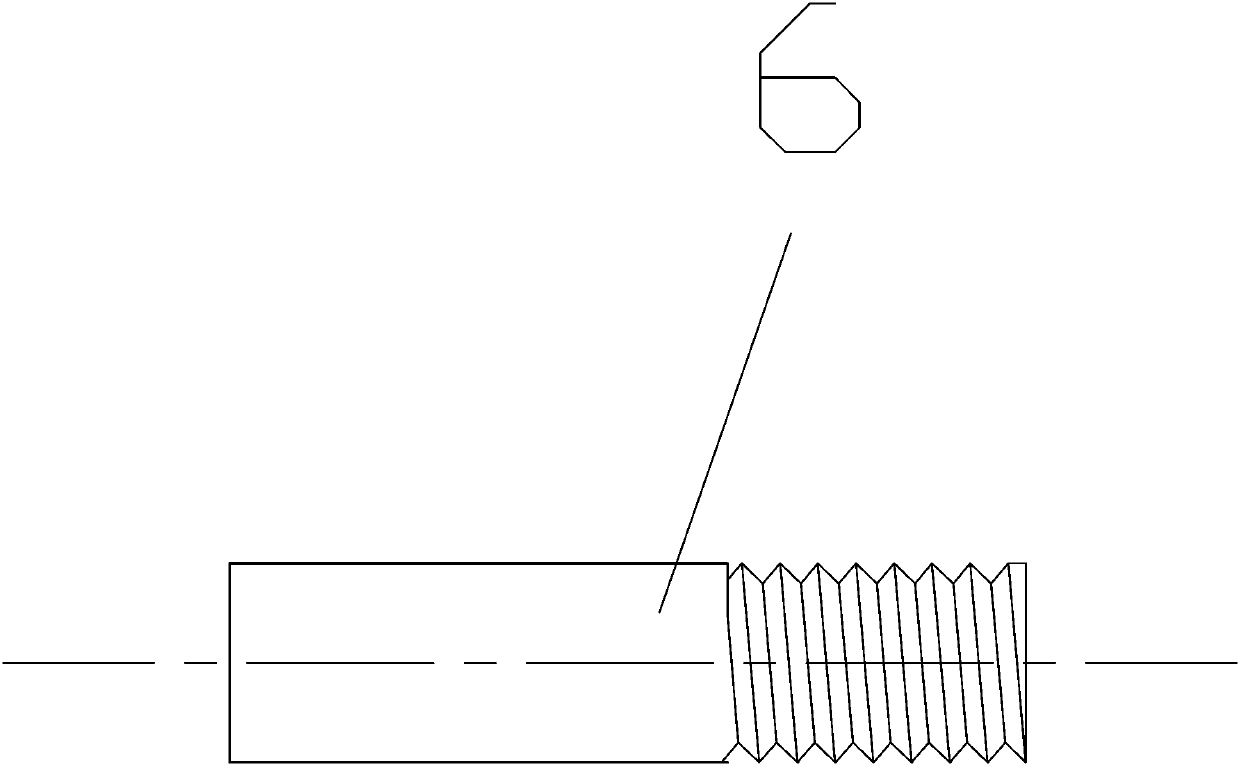

[0062] Such as Figure 1-7 , a kind of overall assembly device for overhead transmission line iron tower fragmentation, which includes a long steel pipe 1, the first short steel pipe 2 and the second short steel pipe 3 are obliquely welded on the two side walls of the long steel pipe 1 respectively, and the long steel pipe 1 1. After the first short steel pipe 2 and the second short steel pipe 3 are welded, an X-shaped rigidity enhancement device 12 is formed, and the four ends of the X-shaped rigidity enhancement device 12 are welded with threaded joints 6, and the other end of the threaded joint 6 is processed There is a threaded column, and the threaded column and the threaded sleeve of the connecting sleeve 7 form a threaded connection. The connecting sleeve 7 adopts a double-ended threaded sleeve, and the other end is connected with a steel pipe 8 through threaded fitting to extend the X-shaped The length of the rigidity enhancing device 12.

[0063] Further, the first s...

Embodiment 2

[0072] Such as Figure 1-18 , The present invention provides a method capable of integrally assembling iron towers of overhead power transmission lines in pieces, and the method includes four parts: pre-construction preparation, arrangement of tools, erection of iron towers, and dismantling of tools.

[0073] The preparation steps before construction are as follows:

[0074] (1) Transport tower materials and construction tools to the construction site;

[0075] (2) Splice the "X" type joints delivered to the site with the standard joints through the threaded joint 6 and the connecting sleeve 7 to make an X-shaped stiffness enhancement device 12, and determine the connection according to the length of the required X-type stiffness enhancement device 12 The number of standard joints requires splicing two sets of X-shaped stiffness enhancement devices 12;

[0076] (3) Assemble the whole piece of tower material 9, 10 at a suitable position;

[0077] (4) Assemble side tower mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com