Driven bevel gear drilling device

A drilling device and bevel gear technology, which is applied in the field of machining, can solve the problems of easy wear and tear of the bottom plate, time-consuming and labor-intensive, inability to realize an automatic production line, etc., and achieves the effects of convenient disassembly and refurbishment, not easy to wear, and easy to install and disassemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

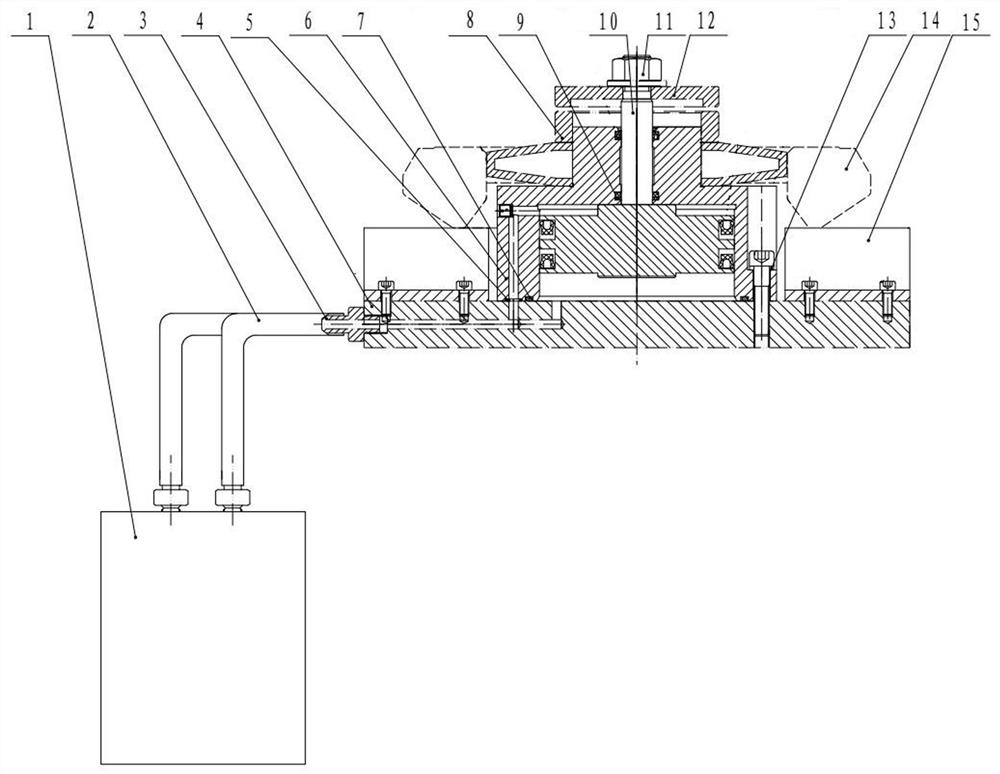

[0014] Such as figure 1 As shown, a driven bevel gear drilling device consists of a hydraulic station 1, a high-pressure oil pipe 2, a pipe joint 3, a bottom plate 4, a sealing ring 5, an oil cylinder body 6, a sealing ring 7, a compression ring 8, and a piston ring sealing ring 9. The piston rod 10, the lock nut 11, the gland 12, the spring washer 13, the workpiece 14 and the spacer 15 are composed, the piston rod 10 is installed on the oil cylinder body 6, and the oil cylinder body 6, the pipe joint 3 and the spacer 15 are fixed on the bottom plate 4; the base plate 4 is respectively provided with an oil inlet hole and an oil outlet hole, the oil inlet hole and the oil outlet hole are respectively connected with the high-pressure oil pipe 2 through the pipe joint 3, and the high-pressure oil pipe 2 is connected with the hydraulic station 1, and the spring expands, presses The inner hole of the tight ring 8 cooperates with the positioning shaft diameter of the oil cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com