A direct-connected oil-free air compressor and its assembly method

An air compressor and gas compression technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., to achieve the effect of reducing use, shortening maintenance cycle, and long maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The purpose of the invention, technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

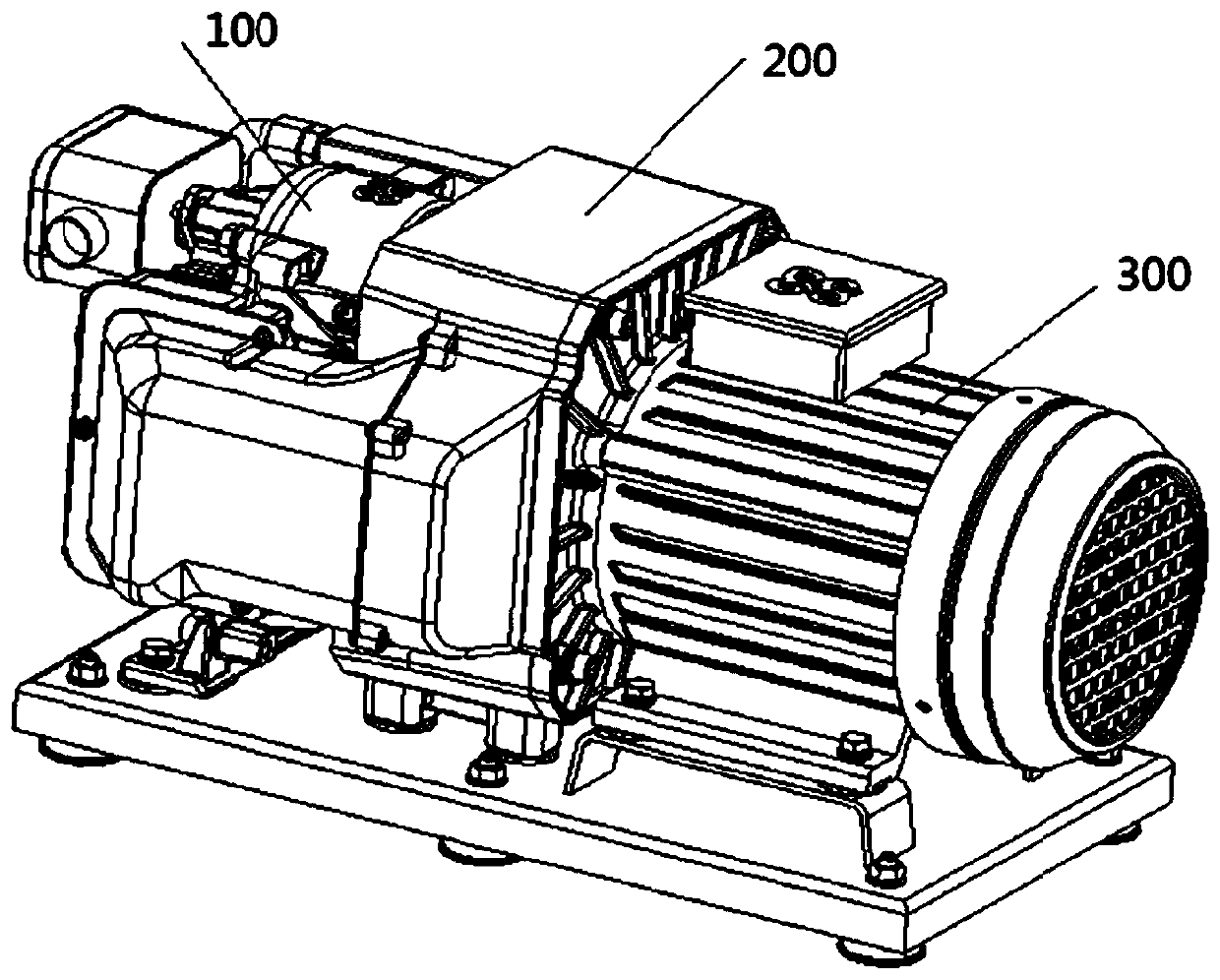

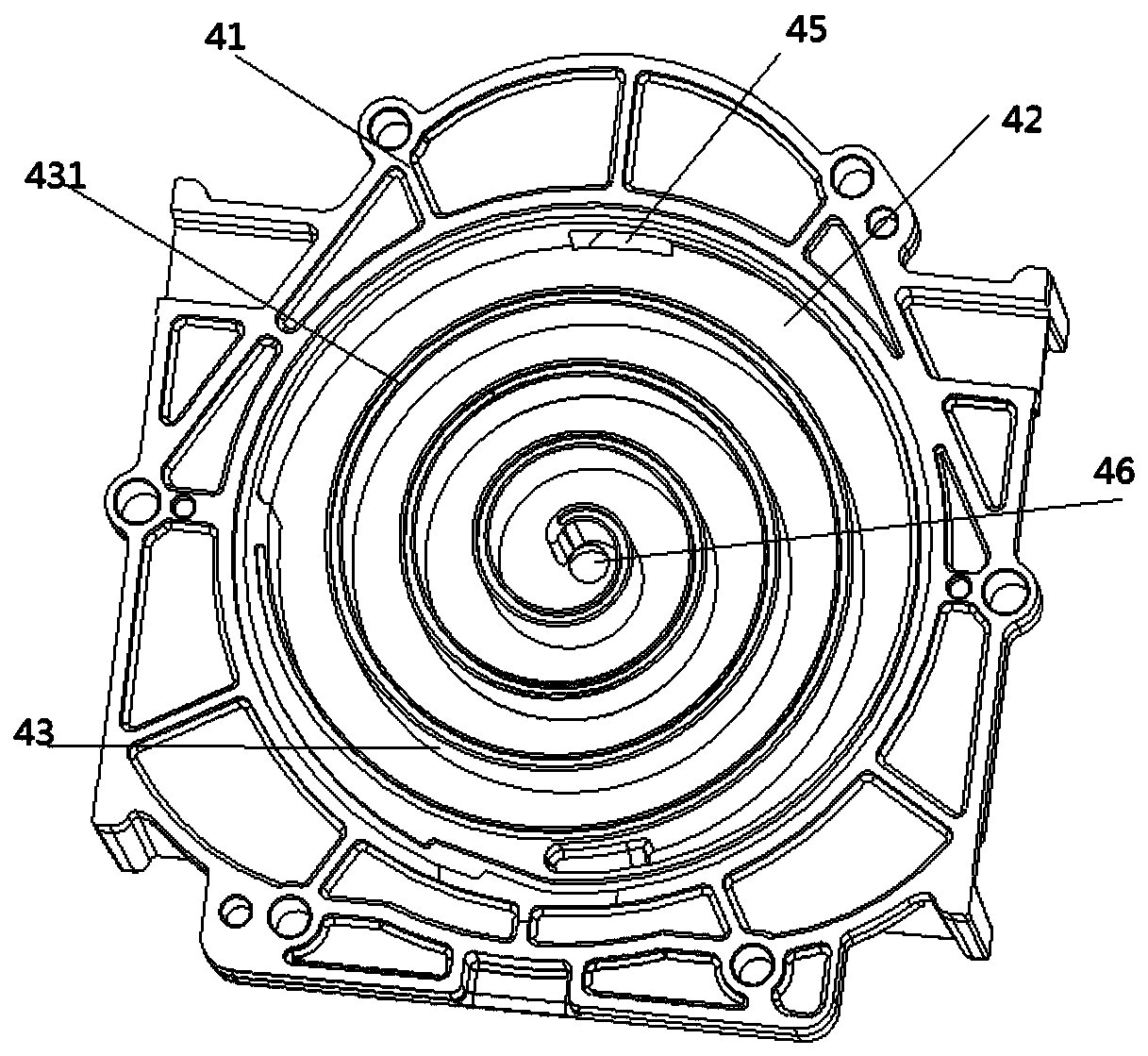

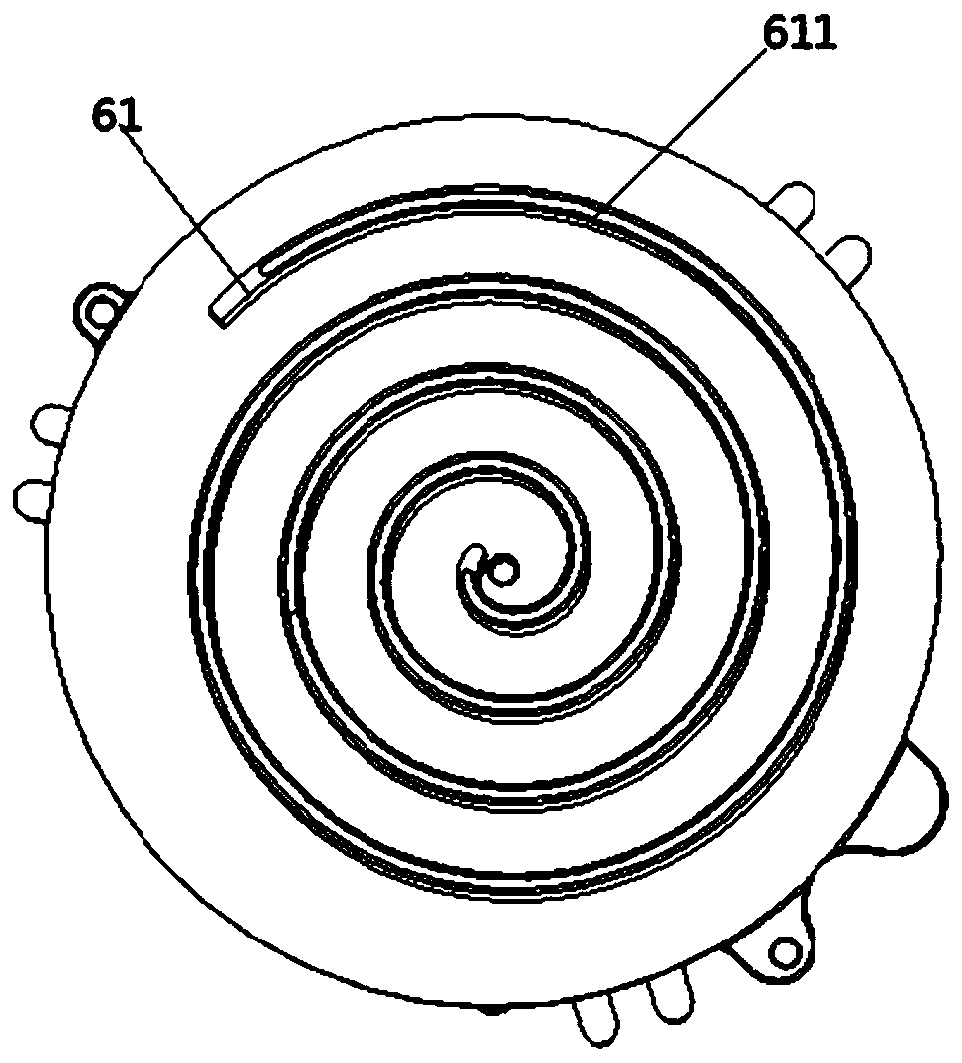

[0030] Please refer to figure 1 and figure 2 , the present invention provides a direct-connected oil-free air compressor, including a gas compression device 100, a power transmission device 200, and a drive device 300, wherein the gas compression device 100 includes an air inlet 45, an exhaust port 46, and a movable scroll 6 and the fixed scroll 4, the movable scroll 6 and the fixed scroll 4 mesh with each other; the driving device 300 is an AC permanent magnet variable frequency motor, including a motor rotor 17, a motor housing 19, a motor front cover 16, a motor rear cover 20, an axial flow Fan 21 and fan casing 23; power transmission device 200 includes bearing seat 7, air guide cover 8, compressor crankshaft 9, bearing 10, casing 11, cooling fan 15, fan casing 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com