A perovskite-type honeycomb monolithic methane catalytic combustion catalyst and preparation method thereof

A methane catalytic combustion, perovskite-type technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of cumbersome catalyst preparation methods and low loading. and other problems, to achieve the effect of preventing agglomeration and sintering, increasing the load and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

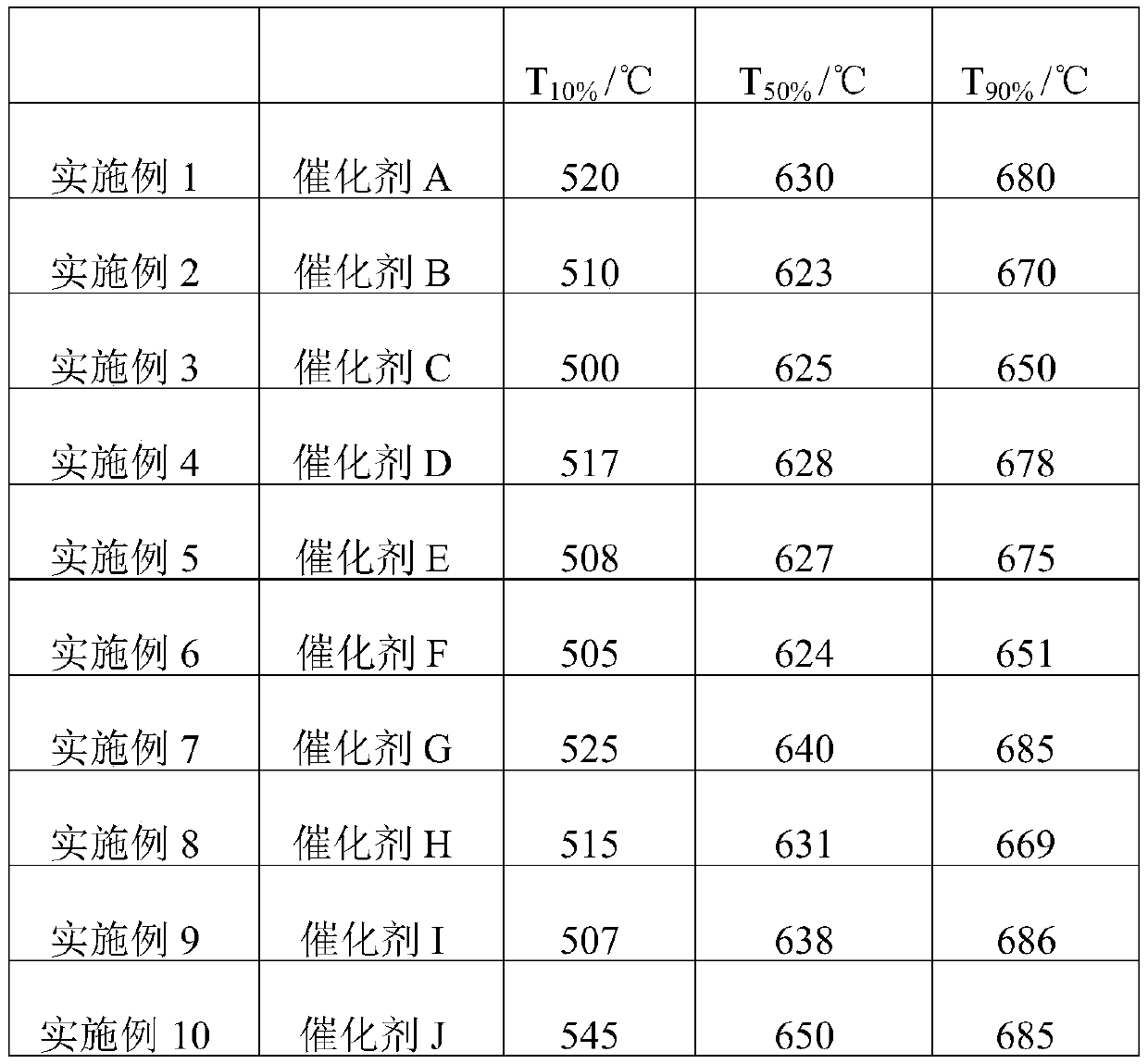

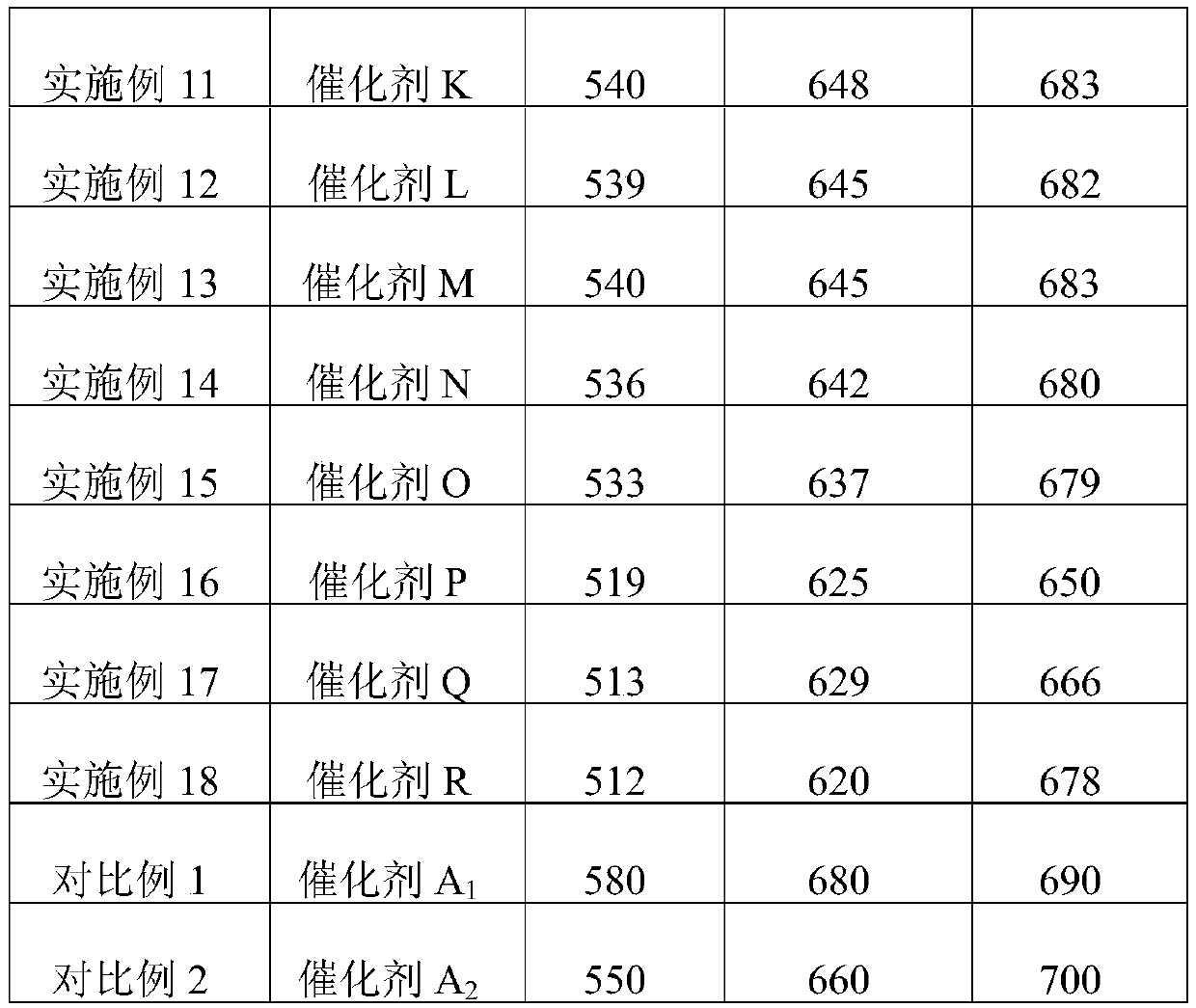

Embodiment 1

[0028] The preparation method of the perovskite honeycomb monolithic methane catalytic combustion catalyst provided in this embodiment comprises the following steps:

[0029] A 300-mesh cordierite with a diameter of 2.5 cm and a height of 7.5 cm was used as a honeycomb carrier; lanthanum nitrate, calcium nitrate, iron nitrate, and manganese nitrate were formulated into an aqueous solution of the precursor of the perovskite-type active component; the metal The molar ratio of ion lanthanum: calcium: iron: manganese is 9:1:1:9, and the total molar concentration of metal ions is 1.5mol / L;

[0030] The above-mentioned cordierite honeycomb carrier was impregnated into the aqueous solution of the precursor of the above-mentioned active component, fully impregnated, dried naturally, dried at 120°C for 5.5h, and then calcined at 800°C for 2.5h to obtain catalyst A, in which the active component was The loading on the carrier was 20%.

Embodiment 2

[0032] The preparation method of the perovskite honeycomb monolithic methane catalytic combustion catalyst provided in this embodiment comprises the following steps:

[0033] A 300-mesh mullite with a diameter of 2.5 cm and a height of 7.5 cm is used as a honeycomb carrier; lanthanum nitrate, calcium nitrate, iron nitrate, and manganese nitrate are formulated into an aqueous precursor solution of a perovskite-type active component; The molar ratio of metal ion lanthanum: calcium: iron: manganese is 9:1:1:9, and the total molar concentration of metal ions is 1.5mol / L;

[0034] Immerse the above-mentioned mullite honeycomb carrier into the aqueous solution of the precursor of the above-mentioned active component, fully impregnate it, dry it naturally, dry it at 120°C for 5.5h, and then calcinate it at 800°C for 2.5h to obtain Catalyst B, in which the active component The loading on the carrier was 21%.

Embodiment 3

[0036] The preparation method of the perovskite honeycomb monolithic methane catalytic combustion catalyst provided in this embodiment comprises the following steps:

[0037] A 300-mesh aluminum oxide with a diameter of 2.5 cm and a height of 7.5 cm was roasted at 950 ° C for 2.5 hours and then used as a honeycomb carrier; lanthanum oxide, calcium oxide, iron oxide, and manganese oxide were dissolved in nitric acid to form perovskite The precursor aqueous solution of type active component; Wherein metal ion lanthanum: Calcium: Iron: The molar ratio of manganese is 9:1:1:9, and the total molar concentration of metal ion is 1.5mol / L;

[0038] Immerse the calcined alumina carrier into the aqueous solution of the precursor of the active component, fully impregnate it, and dry it naturally. After drying at 120°C for 5.5h, it is calcined at 800°C for 2.5h to obtain catalyst C, wherein the active component The loading on the carrier was 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com