Workpiece grinding method and polishing pad dressing method

A grinding method and technology of grinding pads, which are applied in the control of workpiece feed movement, grinding machine tools, grinding tools, etc., can solve problems such as unclear images and inability to obtain high-precision information of grinding pads, and achieve the effect of easy grinding management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

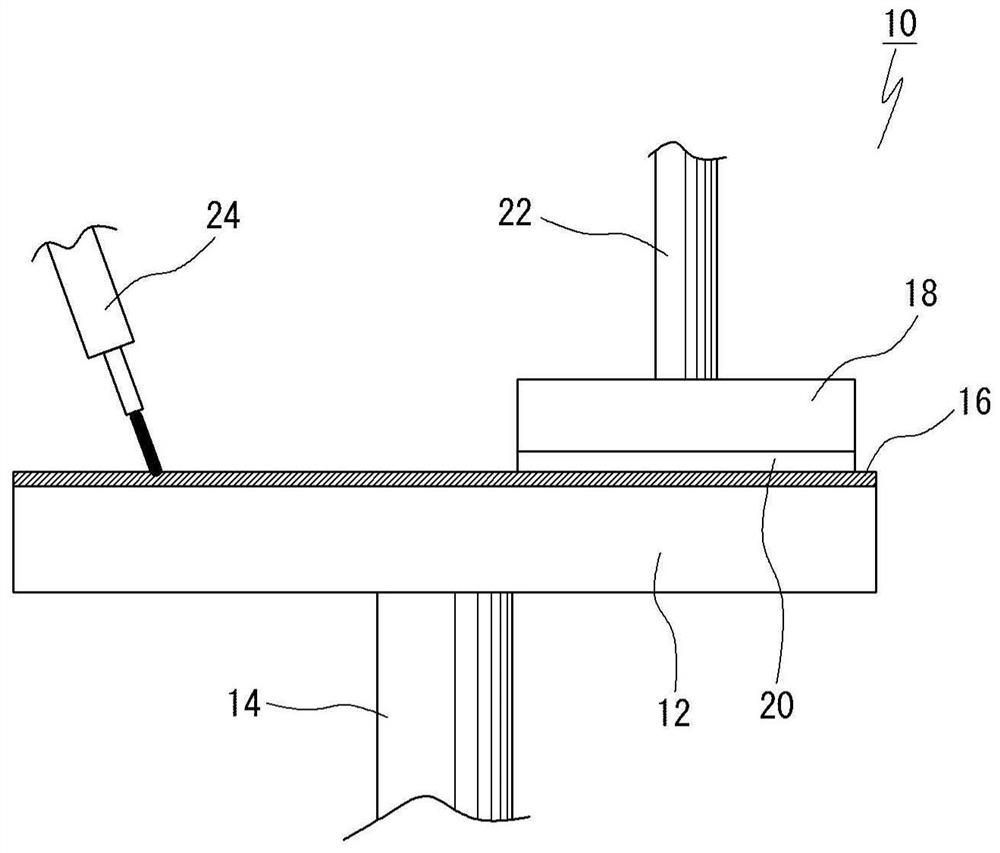

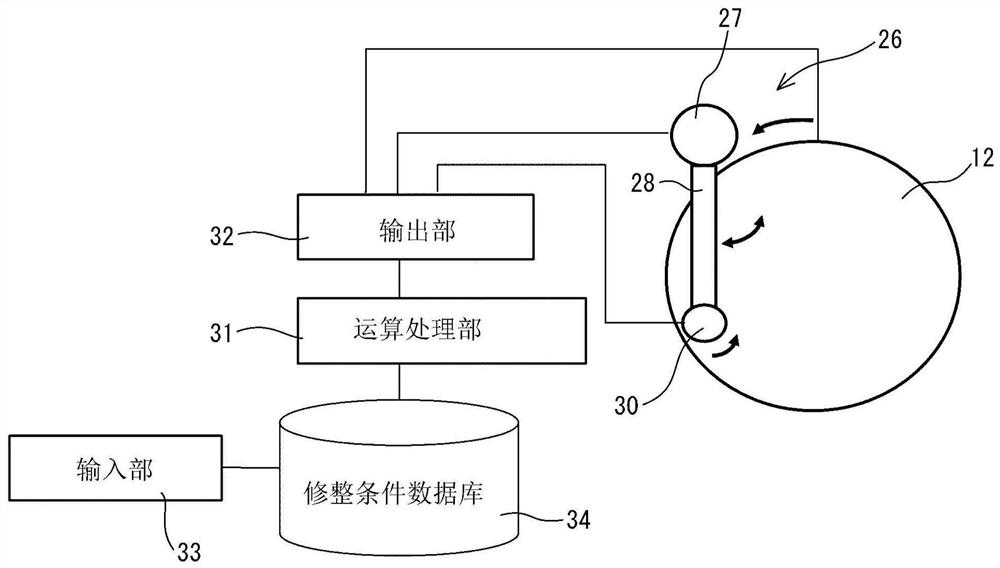

[0039] figure 1 It is an explanatory diagram showing the outline of the polishing device 10 .

[0040] Reference numeral 12 denotes a platform, which rotates in a horizontal plane around a rotating shaft 14 by a known drive mechanism (not shown). A polishing pad 16 made of, for example, foamed polyurethane as a main material is pasted on the upper surface of the platform 12 .

[0041] 18 is a grinding head, which holds a workpiece (semiconductor wafer, etc.) 20 to be ground on its lower surface side. The grinding head 18 rotates about the rotation axis 22 . In addition, the polishing head 18 can move up and down by a vertical movement mechanism (not shown) such as an air cylinder.

[0042] 24 is a slurry supply nozzle, which supplies slurry (polishing liquid) onto the polishing pad 16 .

[0043] The workpiece 20 is held on the lower surface side of the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com