Stacking device of flat steel finished products

A technology for steel products and finished products, which is applied to the field of stacking devices for flat steel products, can solve the problems of inconvenient operation, high production cost, complicated equipment, etc., and achieve the effect of simple structure and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

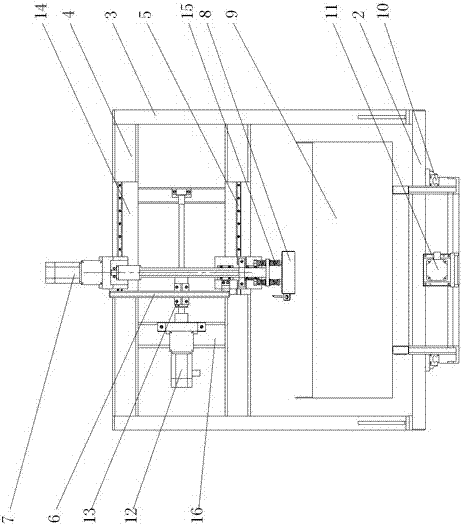

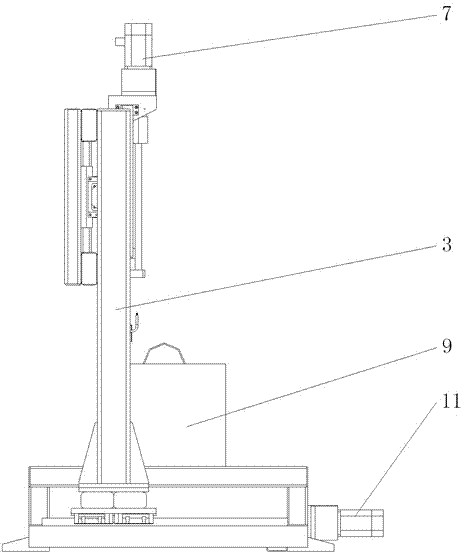

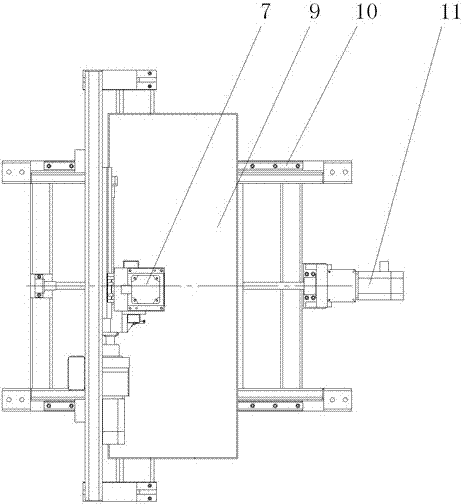

[0018] Example: The flat steel product stacking device in this example, such as figure 1 , figure 2 , image 3 , Figure 4 , including a fixed frame 1, a movable frame is movably connected to the fixed frame, the movable frame includes a bottom plate 2 and a column 3 fixed at both ends of the bottom plate, a pair of beams 4 are fixed on the column, and X To the guide rail 5, a sliding saddle 6 is movably connected to the two X-direction guide rails, and the sliding saddle is connected with a driving device. The driving device includes an X-direction motor 12, and a reinforcing plate 16 is fixed between the two beams. Strengthen the board. The X-direction motor is connected with a sliding block 13 through a screw mechanism, and the sliding block is fixed on the sliding saddle 6 . The sliding saddle is provided with a Y-direction motor 7 , the Y-direction motor is connected to a permanent magnet suction cup 8 through a screw mechanism, and a buffer spring 15 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com