Shuttle type distribution trolley with automatic extension sealed roller shutter device

A cloth trolley, automatic telescopic technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve problems such as hidden safety hazards of maintenance personnel, and achieve the effect of inhibiting the spread of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

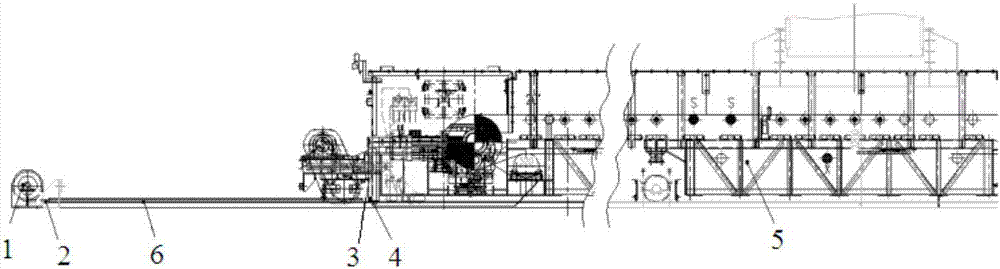

[0010] Such as figure 1 Shown is a shuttle-type fabric trolley with an automatic telescopic sealing roller shutter device, the telescopic end of the sealing roller curtain 2 is fixed on the shuttle-type fabric trolley 5 through the lock device 3, and covers the idle chute as the shuttle-type fabric trolley 5 moves 5. The spring reel 1 is fixed at the terminal point of the shuttle cloth trolley 5, the spring of the spring reel 1 is connected with the sealing roller curtain 2, and the sealing roller curtain 2 is automatically retracted into the spring reel 1 under the action of the spring force; A photoelectric switch 4 for detecting whether the sealing roller blind 2 is automatically crimped is installed on the type cloth dolly 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com