Tobacco leaf stacking tent ventilation, dehumidification and adsorption device

An adsorption device and tent technology, applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problems of tobacco leaf quality decline, tobacco leaf dry matter loss, etc., and achieve the effects of reducing damage, simple structure, and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

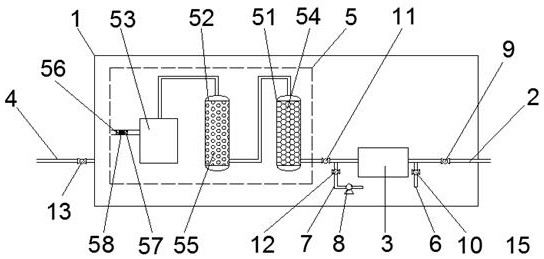

[0029] A ventilation, dehumidification and adsorption device 5 for a tobacco stack tent, comprising a tobacco stack tent 1, in which stacked tobacco leaves are stored, and one side of the tobacco stack tent 1 is connected to a dehumidifier 3 through a ventilation pipe 2, which The other side (the other side refers to the side opposite to the ventilation pipe 2 on the smokestack tent 1) is connected with an exhaust pipe 4, and the dehumidifier 3 can have its own power supply or be connected to an external power supply. The condensed water produced by the dehumidifier 3 can be discharged to the outside of the smokestack tent 1 through pipelines or collected in a container in the smokestack tent 1 and taken out regularly. The side of the dehumidifier 3 away from the ventilation pipe 2 is connected with an adsorption device 5 through a pipeline. .

[0030] A first pipeline 6 is connected to the ventilation pipe 2 , a second pipeline 7 is connected to the pipeline connecting the de...

Embodiment 2

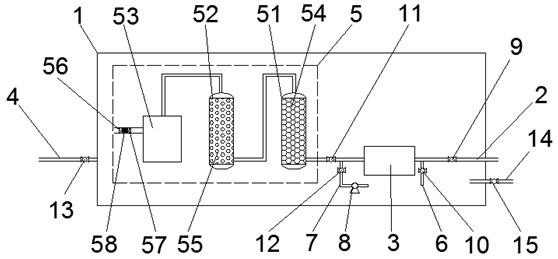

[0046] A ventilation, dehumidification and adsorption device 5 for a tobacco stack tent, comprising a tobacco stack tent 1, in which stacked tobacco leaves are stored, and one side of the tobacco stack tent 1 is connected to a dehumidifier 3 through a ventilation pipe 2, which The other side (the other side refers to the side opposite to the ventilation pipe 2 on the smokestack tent 1) is connected with an exhaust pipe 4, and the dehumidifier 3 can have its own power supply or be connected to an external power supply. The condensed water produced by the dehumidifier 3 can be discharged to the outside of the smokestack tent 1 through pipelines or collected in a container in the smokestack tent 1 and taken out regularly. The side of the dehumidifier 3 away from the ventilation pipe 2 is connected with an adsorption device 5 through a pipeline. .

[0047] A first pipeline 6 is connected to the ventilation pipe 2 , a second pipeline 7 is connected to the pipeline connecting the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com