Vertical cylinder lifting fixture

A vertical hoisting and barrel technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem of easy slipping of the barrel, and achieve the effects of preventing slipping, improving stability, and increasing clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

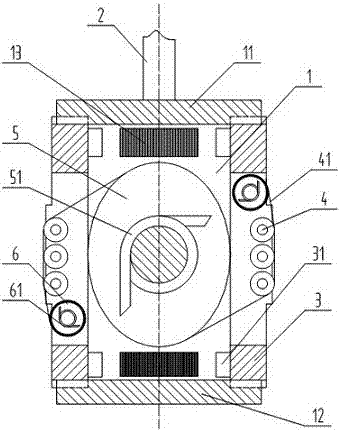

[0015] The reference signs in the accompanying drawings of the description include: base 1, upper sliding seat 11, lower seat 12, electromagnet 13, pull rod 2, slider 3, permanent magnet 31, pulley 4, belt 41, cam 5, first Torsion spring 51, reel 6, second torsion spring 61.

[0016] The embodiment is basically as attached figure 1 Shown:

[0017] Cylinder vertical lifting jig, including a base 1 and a pull rod 2, wherein the pull rod 2 is connected to the upper end of the base 1, and also includes two sliders 3, the two sliders 3 are arranged opposite and slidably connected to the base 1, the base The seat 1 includes an upper slide seat 11 and a lower slide seat 12. The inner sides of the upper slide seat 11 and the lower slide seat 12 are provided with a chute whose cross section is a "convex" shape. The upper and lower ends of the slider 3 are respectively provided w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap