Railway vacuum sewage unloading treatment system

A technology of sewage treatment and vacuum, which is applied in the field of railway vacuum sewage discharge treatment system and sewage treatment. It can solve the problems of low manure efficiency, affecting train speed, increasing train load, etc., and achieves high sewage treatment efficiency, simple structure and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

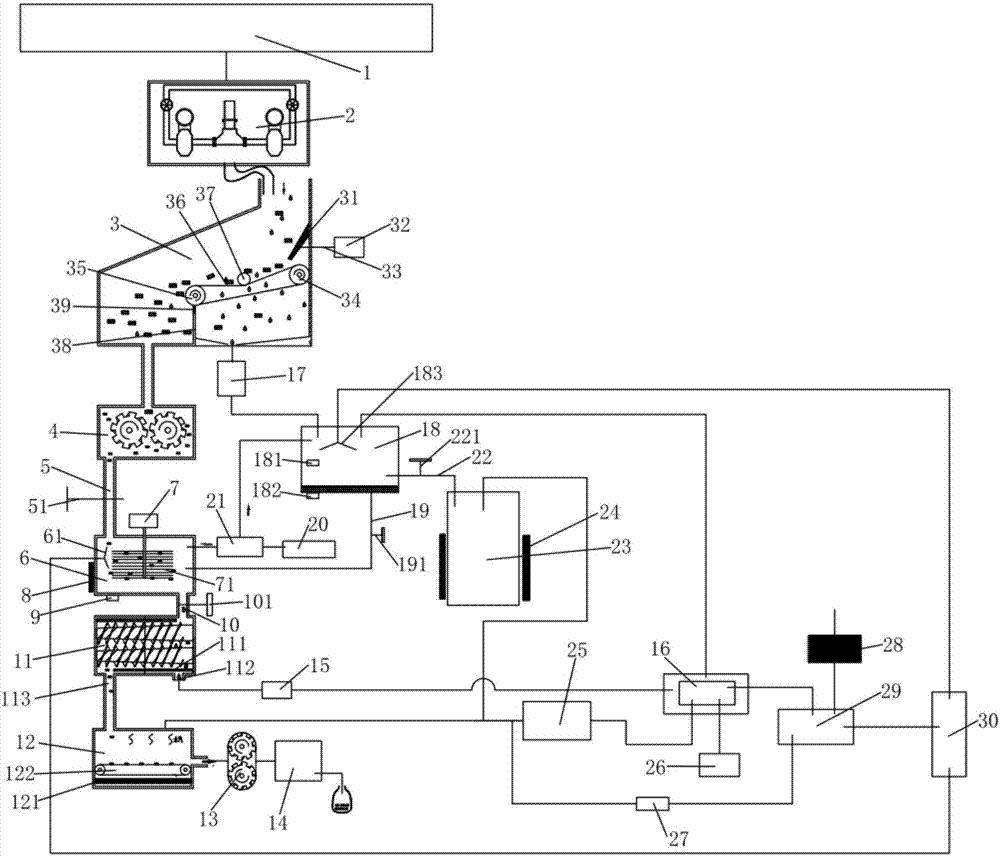

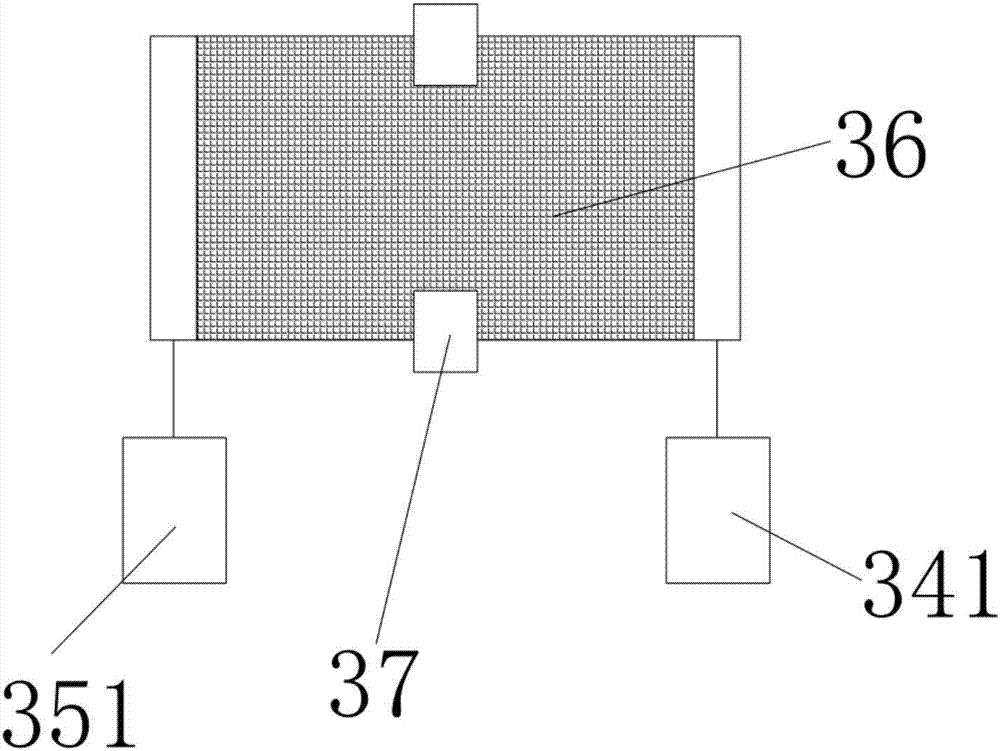

[0019] refer to figure 1 with figure 2 , a railway vacuum unloading treatment system of the present invention, comprising a manure collection box 1, a squeezing device 11 and a cultured bacteria box 20, the manure collection box 1 is connected to the entrance of the vacuum absorption device 2 through a pipeline, and the vacuum absorption The outlet of the device 2 is connected with the inlet of the preliminary filter storage tank 3 through a pipeline, the first filter storage tank 3 is provided with a first vibrating roller 34 and a second vibrating roller 35 inside, and the first vibrating roller 34 and the second vibrating roller 35 are provided with Vibrating screen 36, vibrating pressure rollers 37 are arranged on both sides of the middle part of the vibrating screen 36, and a flexible buffer plate 31 is arranged on the side wall of the preliminary filter storage box 3, and the flexible buffer plate 31 is positioned directly above the first vibrating roller 34, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com