Styrene-based optical resin composition

A styrenic resin, styrenic technology, applied in optics, optical components, light guides, etc., can solve the problems of decreased brightness and transmittance of displays, and achieve low water absorption, low water absorption, and excellent colorless transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-33、 comparative example 1-1~1-9

[0113] With the content shown in Table 2, using a single-screw extruder with a screw diameter of 40 mm, styrene resins A-1 to A-3 and additives were melt-kneaded at a cylinder temperature of 230°C and a screw speed of 100 rpm to obtain Particles. The additives used in Table 2 are as follows.

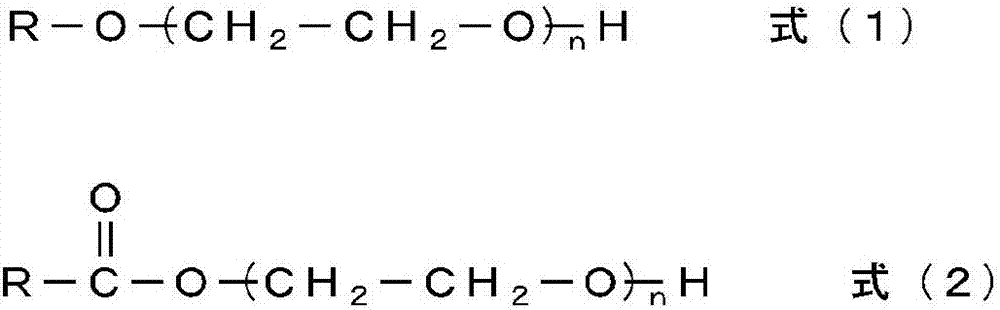

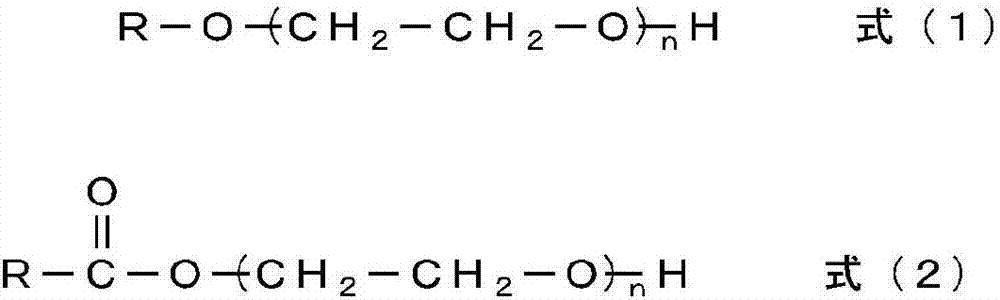

[0114] B-1: Vinyl dodecyl polyoxyethylene ether ethylene oxide average added mole number = 25 (EMULGEN 123P manufactured by Kao Corporation)

[0115] B-2: Vinyl octadecyl polyoxyethylene ether ethylene oxide average added mole number = 12 (EMULGEN 320P manufactured by Kao Corporation)

[0116] B-3: Vinyl dodecyl polyoxyethylene ether ethylene oxide average added mole number = 9 (EMULGEN 109P manufactured by Kao Corporation)

[0117] B-4: Vinyl cetyl polyoxyethylene ether ethylene oxide average added mole number = 7 (EMULGEN 210P manufactured by Kao Corporation)

[0118] B-5: Vinyl dodecyl polyoxyethylene ether ethylene oxide average added mole number = 30 (EMULGEN 130K manufactured by Kao Corpor...

Embodiment 2-1~2-46

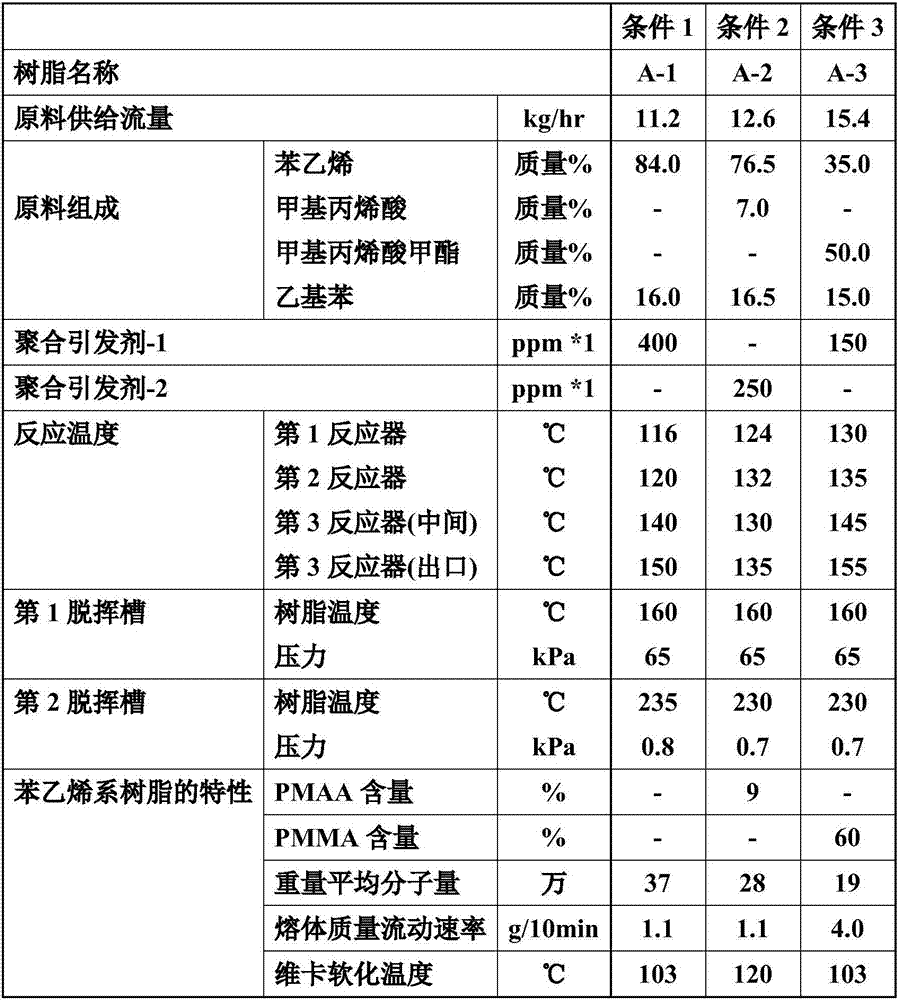

[0169] The first reactor and the second reactor as a complete mixing type stirred tank and the third reactor as a plug flow reactor with a static mixer are connected in series to form the polymerization process, as shown in Table 1. The styrene resin was produced under the conditions shown. The capacity of each reactor is 39 liters for the first reactor, 39 liters for the second reactor, and 16 liters for the third reactor. The raw material solution was prepared with the raw material composition described in Table 1, and the raw material solution was continuously supplied to the first reactor at the flow rate described in Table 1.

[0170] In addition, at the entrance of the third reactor, a hydrophilic additive having a polyether chain was added so as to have the kind and content shown in Table 3. The types of additives and polyethylene glycol used are as follows.

[0171] B-1: Polyethylene glycol with an average molecular weight of 400 (PEG#400 manufactured by NOF Corporation) ...

Embodiment 3-1~3-36

[0212] The evaluation was carried out in the same manner as in Test 2, except that Compound X was not added in Test 3. In Examples 3-1 to 3-32, the styrene resin A-1 produced under Condition 1 was used, and in Examples 3-33 to 3-34, the styrene resin A-2 produced according to Condition 2 was used. In Examples 3-35 to 3-36, the styrene resin A-3 prepared under Condition 3 was used.

[0213] The results are shown in Table 4.

[0214] 【Table 4】

[0215]

[0216] Referring to Table 4, it can be seen that all the examples have excellent whitening suppression effects. In addition, comparing Examples 3-1 to 3-24 and Examples 3-25 to 3-32, it can be seen that when the content of phosphorus-based D is 0.05 to 0.40% by mass and the content of phenol-based E is 0.02 to 0.30% by mass, long-term The thermal stability is particularly excellent. In addition, referring to Examples 3-33 to 3-36, the same results can be obtained when the styrene-based resin is a copolymer of a styrene-based monome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com