Styrene-based resin composition for optical applications, molded product, and light guide plate

A styrene-based resin and styrene-based technology, applied in optics, optical components, instruments, etc., can solve the problems of chromaticity change, backlight brightness decrease, molded product yellowing, etc., and achieve small changes in hue and transmittance , High coloring prevention effect, excellent colorless and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-30

[0111] (Examples 1-1 to 1-30, Comparative Examples 1-1 to 1-10)

[0112] With the contents shown in Table 2, using a single-screw extruder with a screw diameter of 40 mm, styrene-based resins PS-1, PS-2, PS-3 and B and C as additives were added at a barrel temperature of 230 ° C, Melting and kneading was carried out at a screw speed of 100 rpm to obtain granules. Additives B and C used in Table 2 are as follows. Here, additive B represents (b) phosphorus antioxidant, and additive C represents (c) hindered phenolic antioxidant.

[0113] B-1: Tris(2,4-di-tert-butylphenyl) phosphite (Irgafos 168 manufactured by BASF Japan Co., Ltd.)

[0114] B-2: 2,2'-methylenebis(4,6-di-tert-butyl-1-phenyloxy)(2-ethylhexyloxy)phosphorus (ADKSTAB HP-10 manufactured by ADEKA Corporation)

[0115] B-3: Bis(2,4-dicumylphenyl)pentaerythritol diphosphite (Doverphos S-9228 manufactured by Dover Chemical Corporation)

[0116] B-4: 3,9-bis(2,6-di-tert-butyl-4-methylphenoxy)-2,4,8,10-tetraoxa-3,9-diph...

Embodiment 2-1~2-26

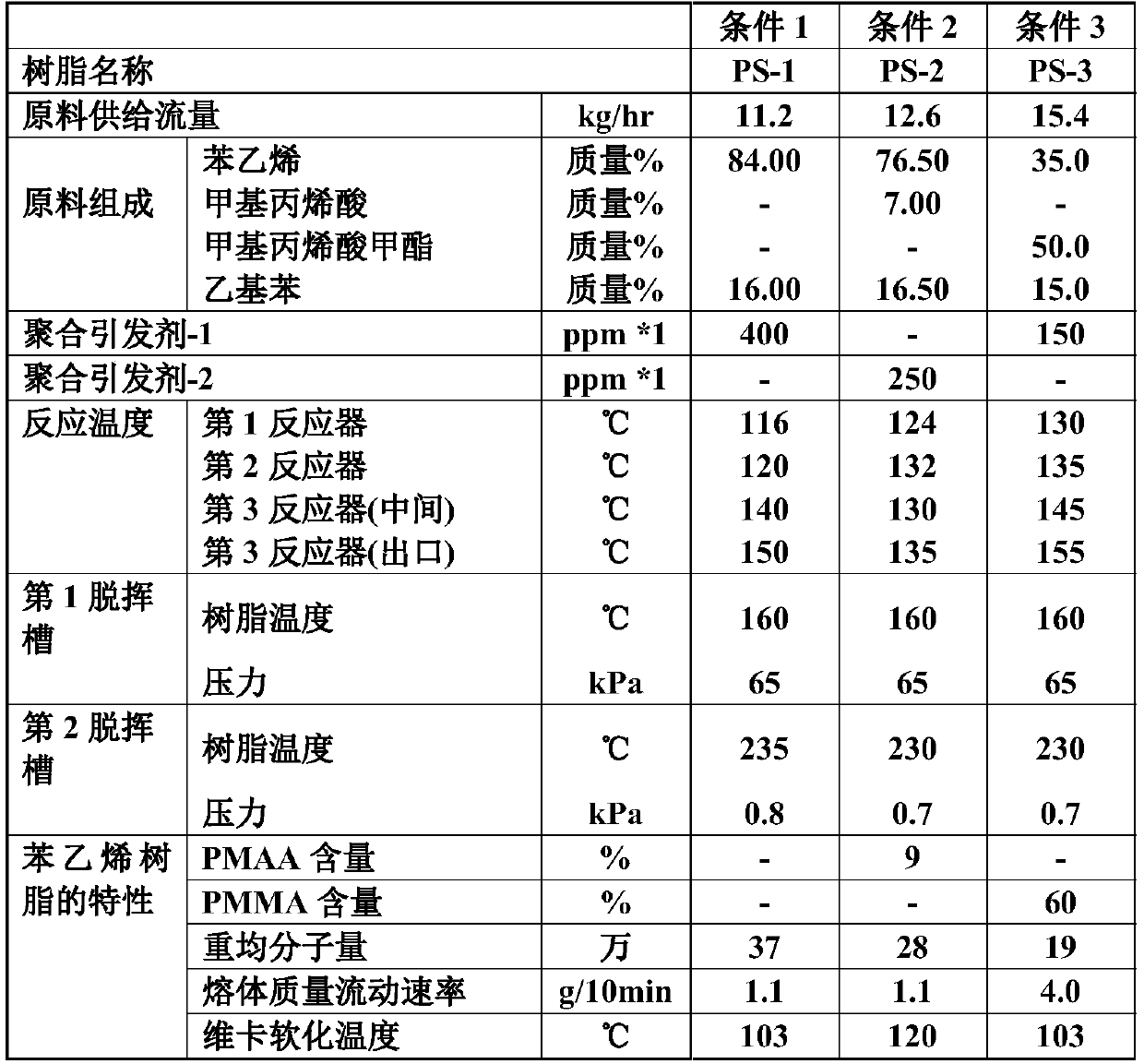

[0144] The first reactor and the second reactor as a complete mixing type stirred tank and the third reactor as a plug flow type reactor with a static mixer are connected in series to constitute a polymerization process, as shown in Table 1. Production of the styrene-based resin was carried out under Condition 1 shown. The capacity of each reactor was 39 liters for the first reactor, 39 liters for the second reactor, and 16 liters for the third reactor. A raw material solution was prepared using the raw material composition described in Condition 1 of Table 1, and the raw material solution was continuously supplied to the first reactor at the flow rate described in Table 1.

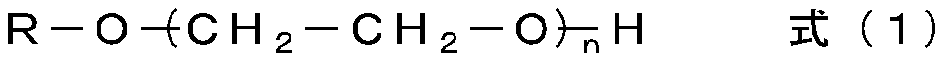

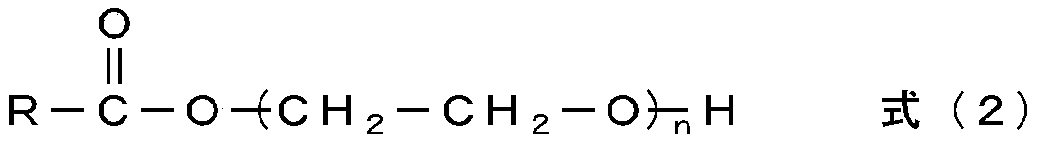

[0145] Moreover, at the inlet of the 3rd reactor, the hydrophilic additive D which has a polyether chain was added so that it may become the kind and content shown in Table 3. The kinds of additives and polyethylene glycols used are as follows.

[0146] D-1: Polyethylene glycol with an average molecular...

Embodiment 3-1~3-18

[0185] Next, using a single-screw extruder with a screw diameter of 40 mm, the styrene-based resin A, B and C as additives were melted and kneaded at a cylinder temperature of 230° C. and a screw speed of 100 rpm to obtain the content shown in Table 5. particles. The symbols of B and C of the additives used in Table 5 are the same as those in Test 1.

[0186] The transmittance, YI value, and whitening suppression effect were measured and evaluated by the method similar to Test 2.

[0187] Table 5 shows the characteristics and evaluation results of each resin composition.

[0188] 【Table 4】

[0189]

[0190] *1 Concentration relative to the mass standard of styrene + methyl methacrylate

[0191] 【table 5】

[0192]

[0193] The molded articles of Examples 3-1 to 3-16, which contain a relatively large amount of (meth)acrylate units, have an excellent whitening suppression effect, excellent initial transmittance and YI value, and are stored at 80°C for 1000 hours The fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com