Light-guiding plate made of styrenic resin

A technology of styrene-based resin and light guide plate, which is applied in the field of light guide plate, can solve the problems of high water absorption and large warpage after water absorption, and achieve the effects of low water absorption, restraining thermal deformation, and preventing yellowing

Active Publication Date: 2013-03-06

TOYO STIRENE CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] Patent Document 2 discloses a light guide plate formed of a styrene-based monomer-(meth)acrylic monomer-system copolymer, the styrene-based monomer-(meth)acrylic-based monomer-system copolymer is 95.5 to 99 It is composed of styrene-based monomers in weight % and 1 to 4.5 weight % of (meth)acrylic monomers, and has a Mw of 160,000 to 350,000, but it shows high water absorption, and the ratio of water absorption and warpage to styrene-based monomers is Large trend of raw material styrenic resin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

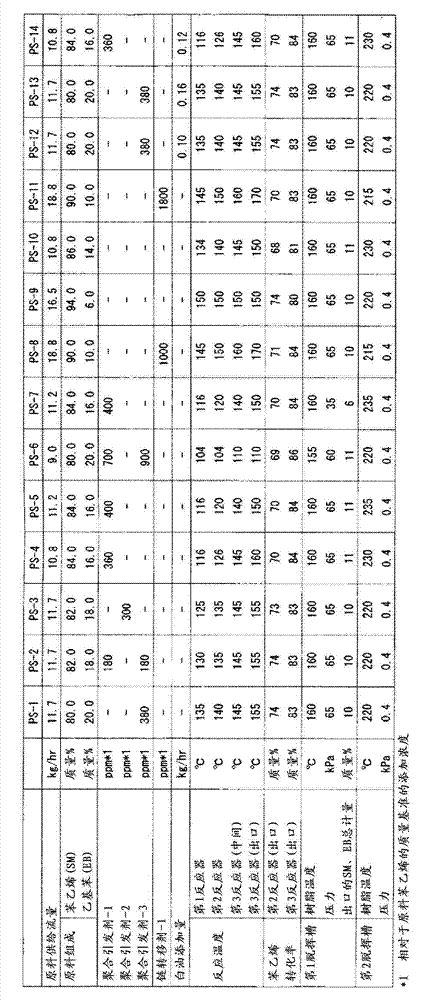

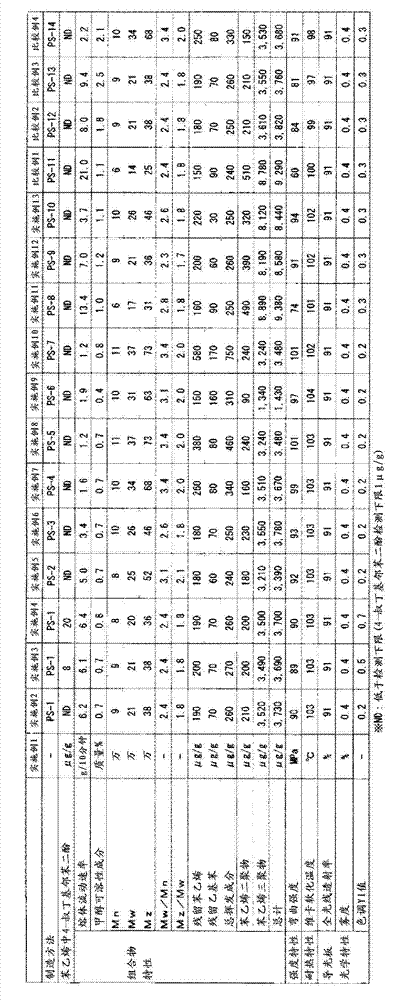

Embodiment 1~12、 comparative example 1~4)

[0095] Table 2 shows properties of each resin.

[0096] Table 2

[0097]

[0098] In the examples, a light guide plate made of a styrene-based resin having excellent heat resistance and little yellowing during molding, and made of a styrene-based monomer was obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Login to View More

Abstract

Provided is a light-guiding plate which is made of a styrenic resin prepared using a styrenic monomer as the raw material and which exhibits excellent heat resistance and rarely yellows during molding. A light-guiding plate made of a styrenic resin that has a methanol-soluble matter content of 1.5% by mass or less and a weight-average molecular weight (Mw) of 150,000 to 450,000.

Description

technical field [0001] The present invention relates to a light guide plate formed of a styrene-based resin using a styrene-based monomer as a raw material. Background technique [0002] As backlights for liquid crystal displays, there are direct type backlights in which a light source is arranged on the front of a display device, and edge-lit backlights in which a light source is arranged on a side surface. Light guide plates are installed in edge-lit backlights to guide light from the side to liquid crystal panels, and are used in a wide range of applications, including televisions, desktop PCs, notebook PCs, mobile phones, and car navigation. [0003] Acrylic resins such as PMMA (polymethyl methacrylate) are mainly used in light guide plates. Although these resins have excellent optical properties such as transparency, they tend to have high water absorption, which may cause warping of molded products. Dimensions Variety. [0004] Therefore, it has been proposed to use ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F21S2/00G02B6/00

CPCG02B1/045G02B6/0001C08L25/04

Inventor 绪方博西野广平小沢道秀

Owner TOYO STIRENE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com