Roadside gutter inlet structure construction method

A construction method and technology of gullies, applied to drainage structures, waterway systems, water supply devices, etc., can solve problems such as poor construction efficiency, reduced construction efficiency, and long processing time, and achieve simple and fast construction methods, avoiding excavation of road surfaces, The effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

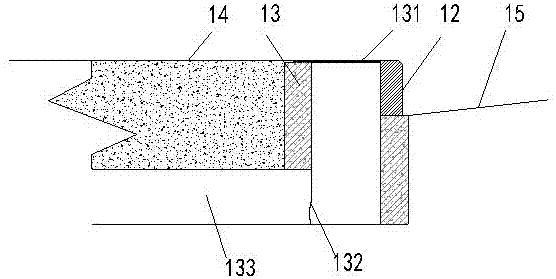

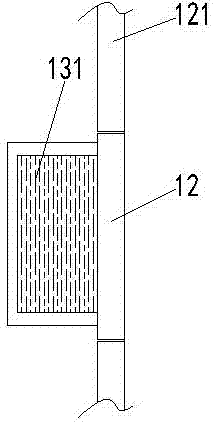

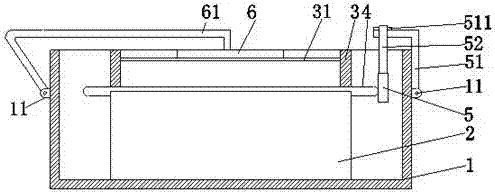

[0036] During specific implementation: if Figure 1~Figure 7 As shown, a construction method of a roadside gully structure, the location of the gully is determined in advance at the construction site and the gully is excavated, a rainwater well shaft 13 is built in the gully hole and a rainwater well shaft wall 13 upper end side is pre-prepared. The rainwater grate 12 is installed at the opening, the upper end of the rainwater well shaft 13 is equipped with a well cover 131, and the lower end is connected to the drainage pipe 133; They are respectively connected with two sections of curbstones 121 on the same side of the road, and the upper ends of the rainwater grate 12 are flush with the upper ends of the curbstones 121 .

[0037] The construction method of the roadside gully structure provided by the present invention is simple and fast, and the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com