Support structure and construction method of recyclable prefabricated collection and drainage extruded and expanded tire piles

A supporting structure and prefabricated technology, applied in the field of building foundation engineering, can solve the problems of inability to realize integrated support and drainage, speed up the construction of foundation pit engineering, environmental pollution of formwork, etc., achieve simple and fast construction method, speed up construction progress, Economically significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

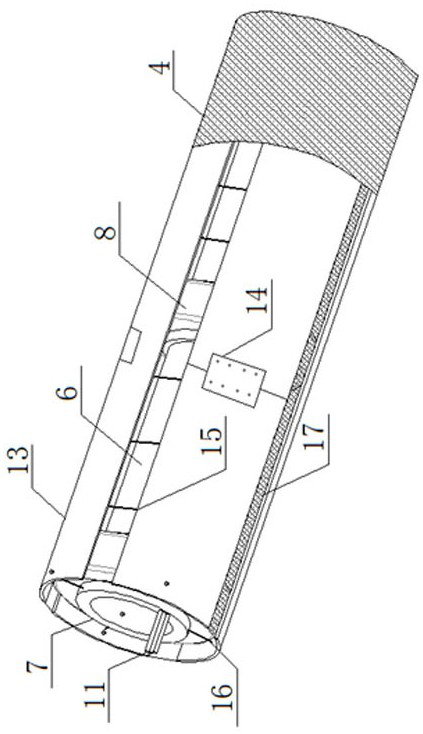

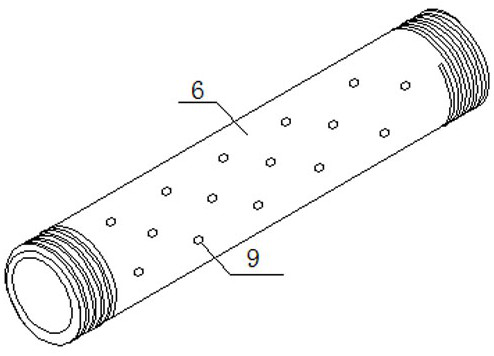

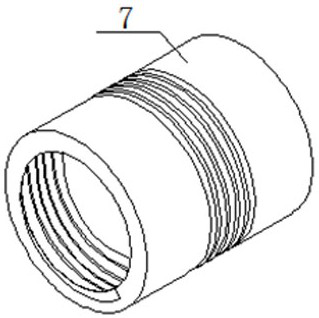

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples. The given examples are only used to explain the present invention and are not limited to this example. After reading the present invention, all equivalent replacements and modifications made within the principle of the present invention belong to the protection scope of the present invention.

[0021]The working principle of the present invention: (1) The principle of preloading and drainage: the carcass and the cylindrical expanding structure are closely attached, and the carcass is once inflated to make the cylindrical expanding structure move toward the soil by extrusion, and the soil is in the The drainage is accelerated under the extrusion of the cylindrical expanding structure. (2) Support principle: After the foundation pit dewatering work is completed, the carcass is inflated twice, and the carcass continues to expand. The cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com