Linear transmission device with lubricating unit

A technology of linear transmission and lubricating oil, which is applied in the direction of transmission, transmission parts, gear lubrication/cooling, etc., and can solve problems such as oil leakage and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

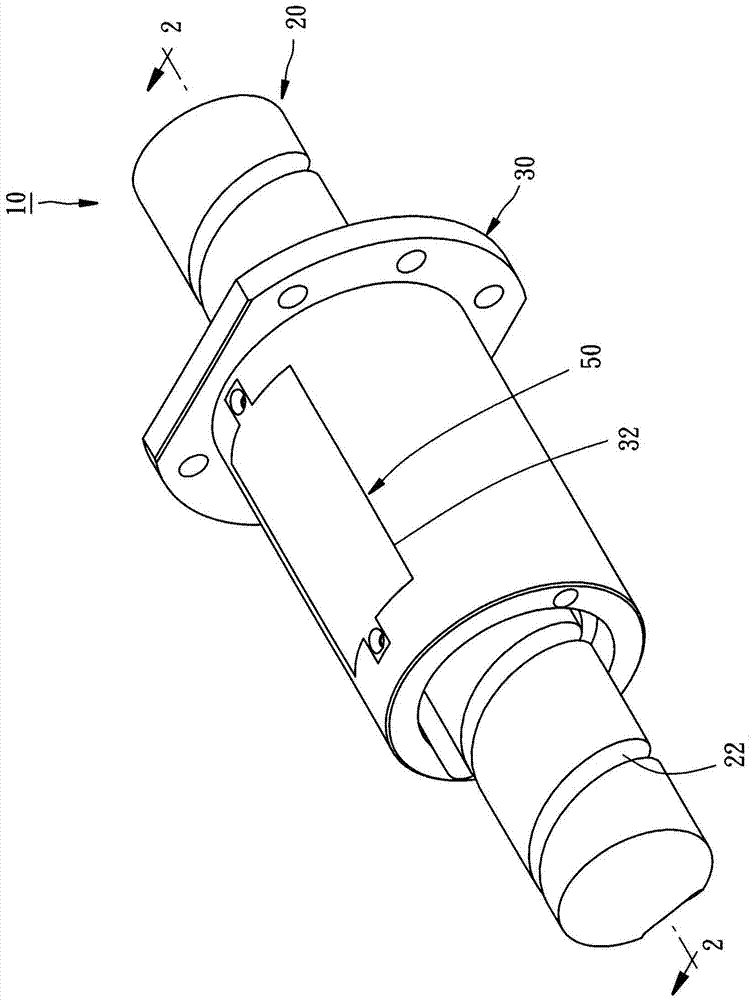

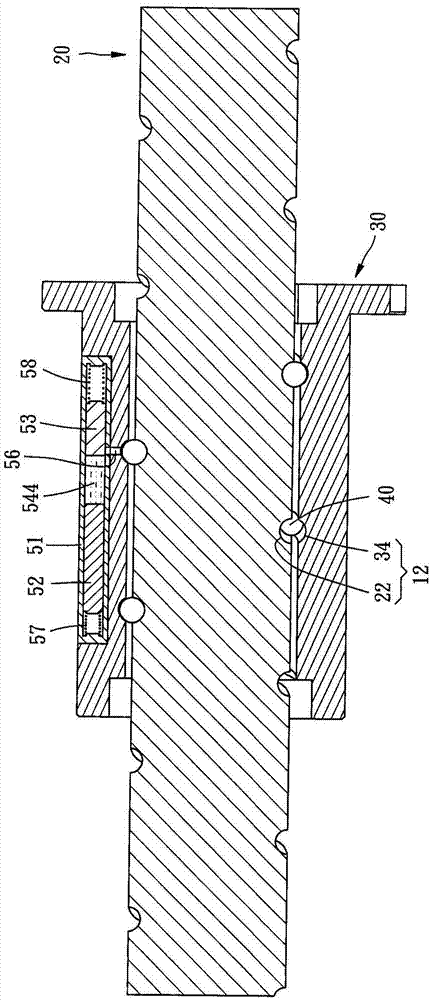

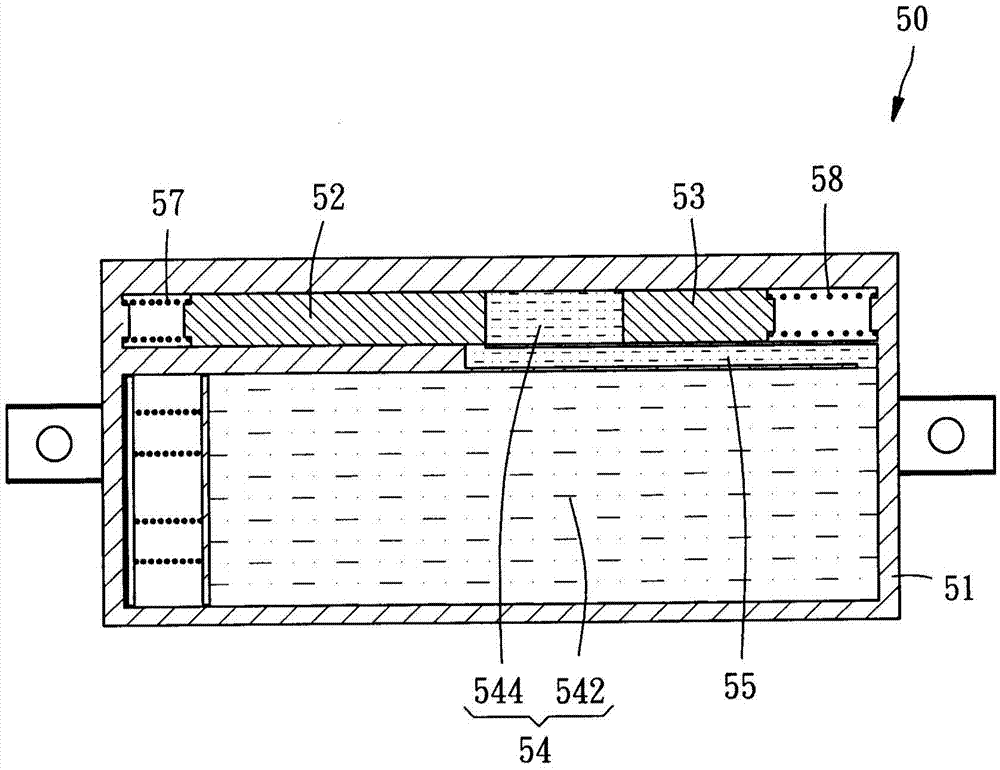

[0024] Please see first figure 1 and figure 2 , The linear transmission device 10 of the first embodiment of the present invention includes a long shaft 20 , a moving body 30 , a plurality of balls 40 , and a lubricating unit 50 . In this embodiment, the linear transmission device 10 is a ball screw, so the long axis 20 is a screw shaft in this embodiment, and the moving body 30 is a nut.

[0025] The outer peripheral surface of the long shaft 20 has an external thread groove 22 .

[0026] The moving body 30 is sheathed on the major axis 20 and can move back and forth along the axial direction of the major axis 20 . The outer peripheral surface of the mobile body 30 has a fuel tank installation groove 32, and the inner peripheral surface of the mobile body 30 has an internal thread groove 34, and the internal thread groove 34 corresponds to the external thread groove 22 of the long axis 20, so that the internal thread groove of the mobile body 30 A load channel 12 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com