A Method of Nonlinear Ultrasonic On-line Monitoring of Metal Material Strain Variation

A non-linear ultrasonic and metal material technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of high equipment cost and complicated detection methods, and achieve the effect of solving high costs and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

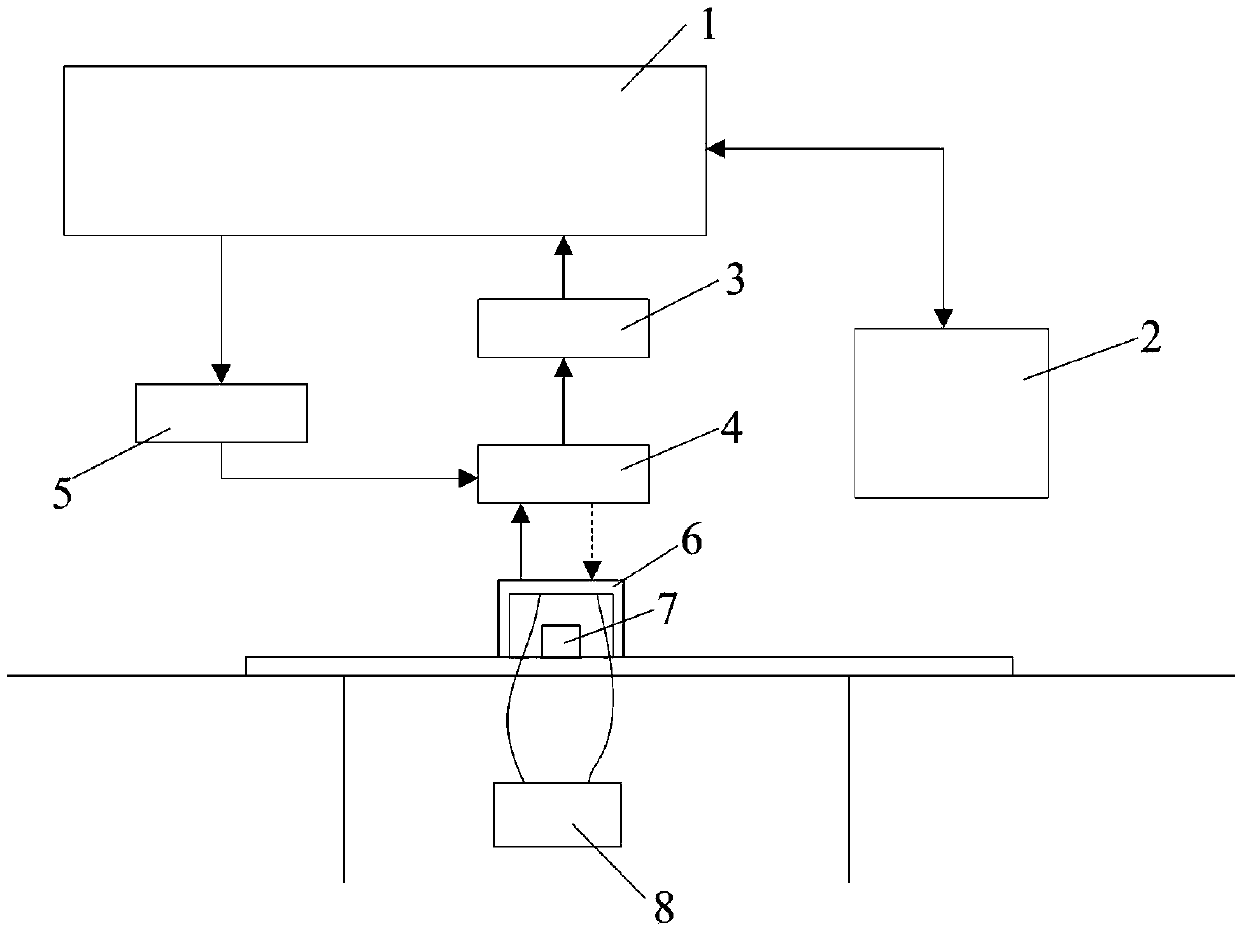

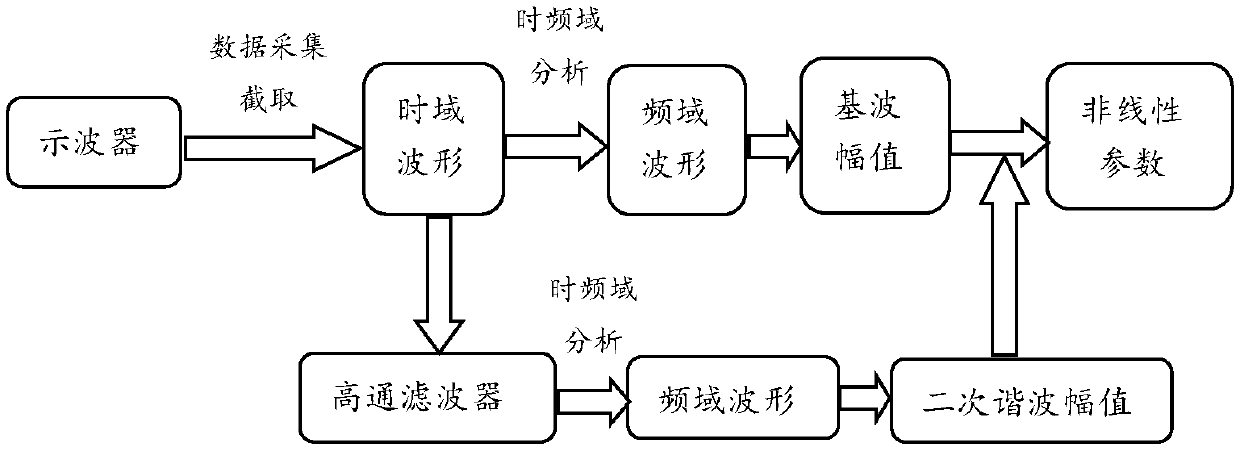

[0042] The invention provides a device for nonlinear ultrasonic on-line monitoring of strain changes of metal materials, which is divided into an on-line strain detection part of metal materials, an acoustic wave emitting and receiving part, and a processing for receiving nonlinear ultrasonic parameters.

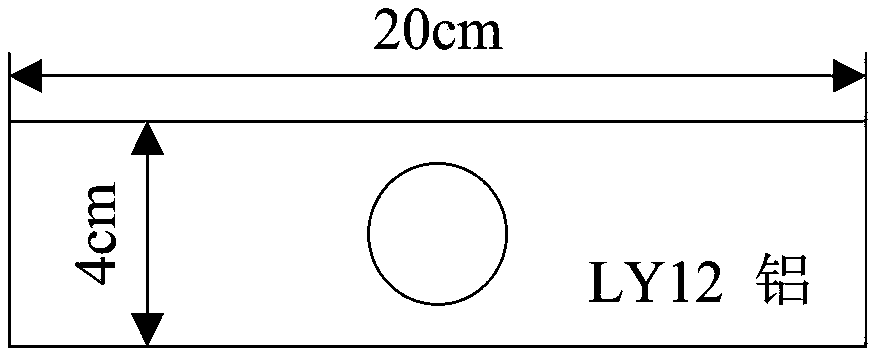

[0043] Step 1: In order to verify this method, make a piece of LY12 aluminum alloy plate whose length*width*height is 20*4*1 (unit: cm), such as figure 1 As shown, the circle in the middle of the specimen is where the probe is placed. Such as figure 1 shown.

[0044] Table 1 Parameters of LY12 aluminum alloy specimens

[0045]

length (cm)

width (cm)

height (cm)

P-wave velocity (m / s)

Shear wave velocity (m / s)

Specimen

20

4

1

6345.85

2365.82

[0046] Step 2: Fix the two ends of the plate and hang a heavy object in the middle to produce certain fatigue. A support frame for online strain monitoring is made on the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com