Mask holder cleaning device and exposure machine

A technology for cleaning devices and masks, which is applied to microlithography exposure equipment, photolithography exposure devices, and optical mechanical equipment. It can solve the problems of low cleaning efficiency and insufficient cleaning degree, and achieve the goals of improving efficiency and quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

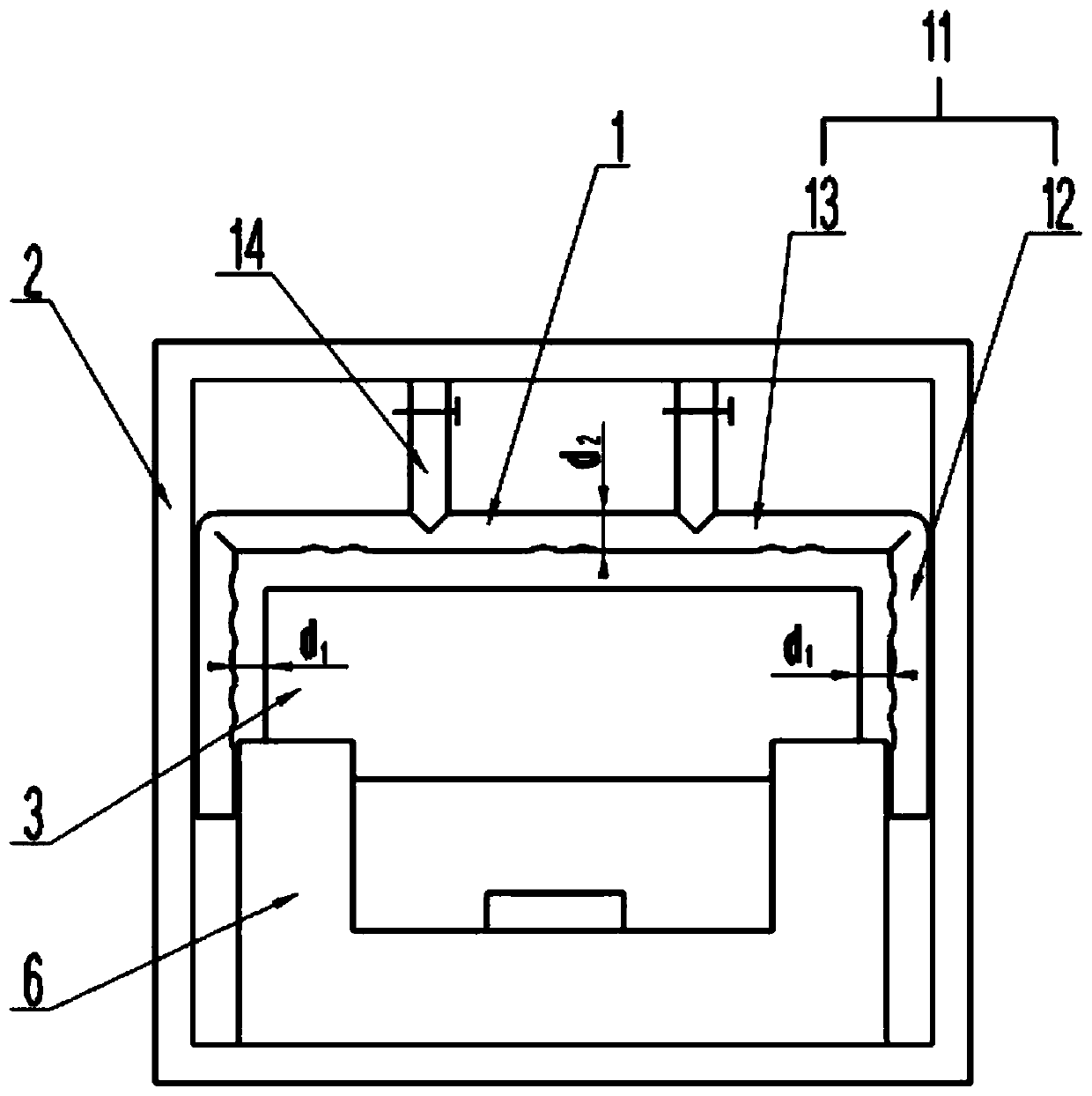

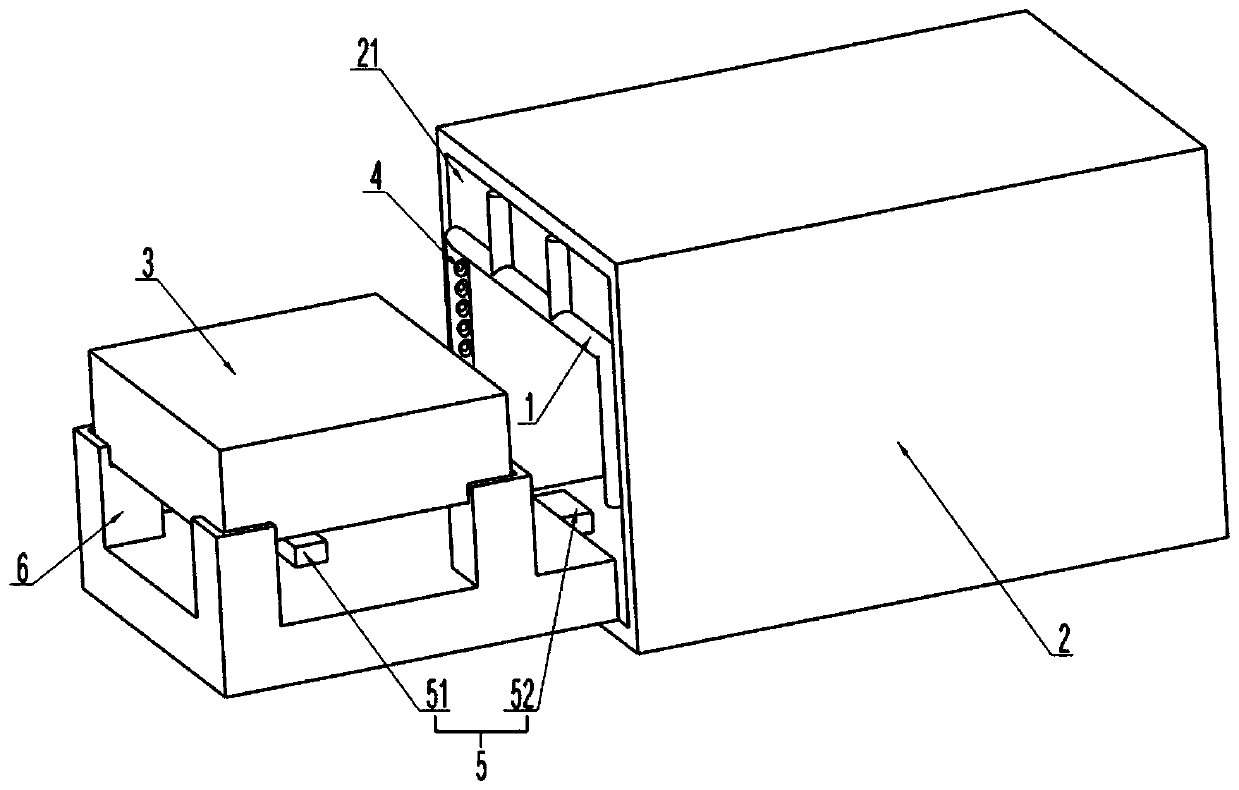

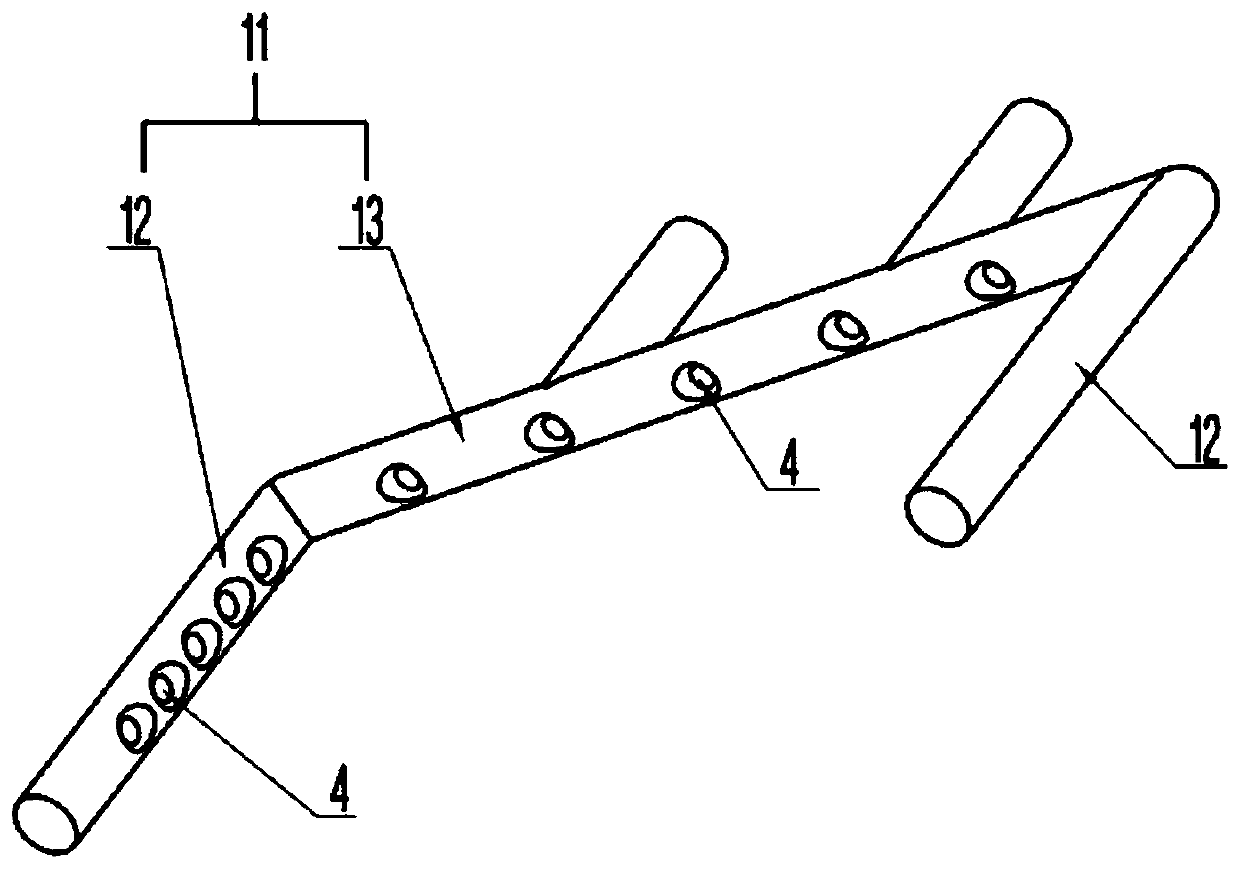

[0038] Such as figure 1 As shown, the present invention provides a photomask holder cleaning device, which includes an adsorption part 1, the adsorption part 1 is fixed at the opening of the photomask exchange chamber 21, the photomask exchange chamber 21 is used to accommodate the photomask holder 3, The suction surface of the suction component 1 is set facing the surface of the photomask holder 3 .

[0039] Specifically, the mask exchange chamber 21 is disposed inside the exposure machine 2 . The reticle exchange chamber 21 is provided with an opening for the reticle holder 3 to enter or exit, and the adsorption component 1 is located at the opening. Movement, during the movement, the adsorption part 1 will suck away the foreign matter on the photomask holder 3; when performing the operation on the machine, the photomask holder 3 moves from the outside of the photomask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com