Preparation method of touch sensor and touch sensor

A touch sensor and etching paste technology, applied in the touch field, can solve the problems of large manufacturing difficulty, small process window, low pollution degree, etc., and achieve the effects of facilitating curing and molding, increasing yield, and solving shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

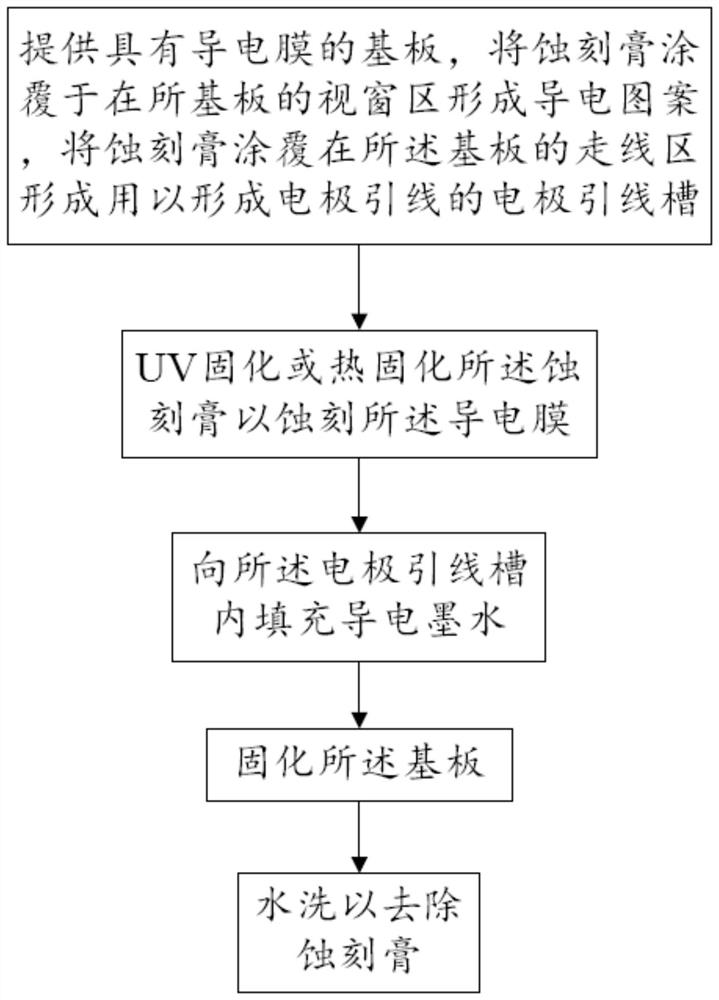

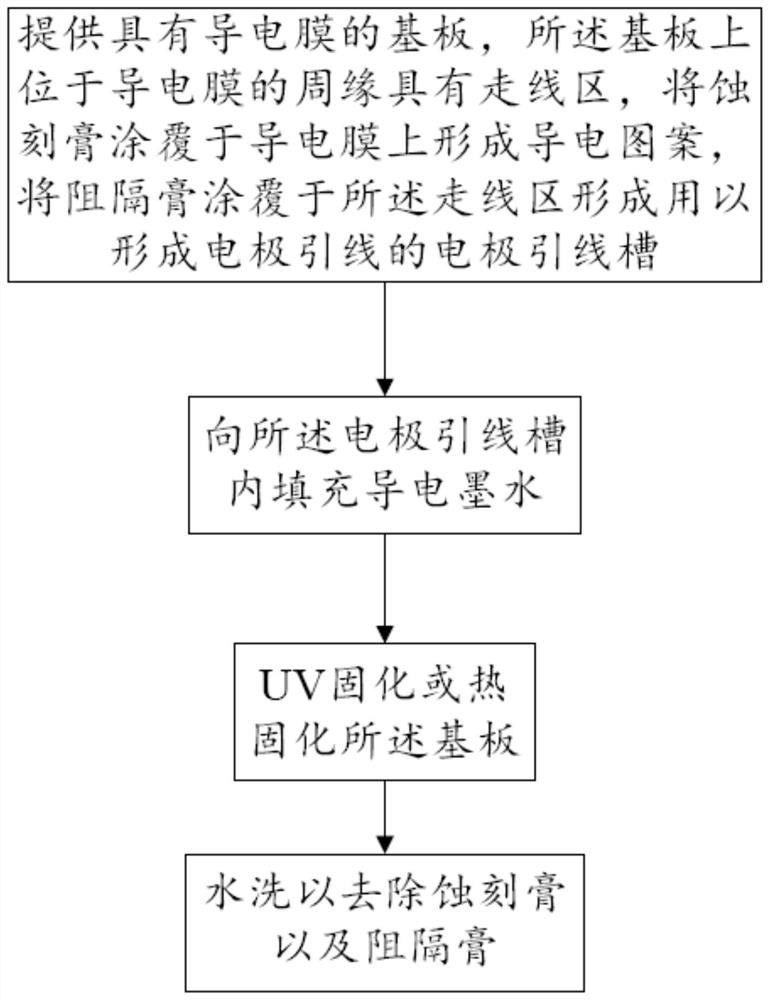

[0027] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings, please refer to Figure 1 to Figure 2 Shown is a preferred embodiment of the present invention.

[0028] Please refer to figure 1 As shown, in the first embodiment of the present invention, the present invention provides a method for manufacturing a touch sensor and a touch sensor prepared by using the method for manufacturing a touch sensor, the touch sensor includes a substrate with a conductive film The substrate includes a window area and a wiring area located around the window area, and the conductive film covers the window area and the wiring area.

[0029] Described preparation method comprises the steps:

[0030] S1: Provide the above-mentioned substrate with a conductive film, apply the etching paste to the window area of the substrate to form a conductive pattern, and apply the etching paste to the wiring area of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com