Noise testing method and system for acoustic products

A test method and product technology, applied in the direction of electrical components, etc., can solve the problems of inability to judge the performance of semi-finished products, the largest amplitude diaphragm ring folds, and product resonance frequency changes, etc., to achieve high test efficiency, simple test methods, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

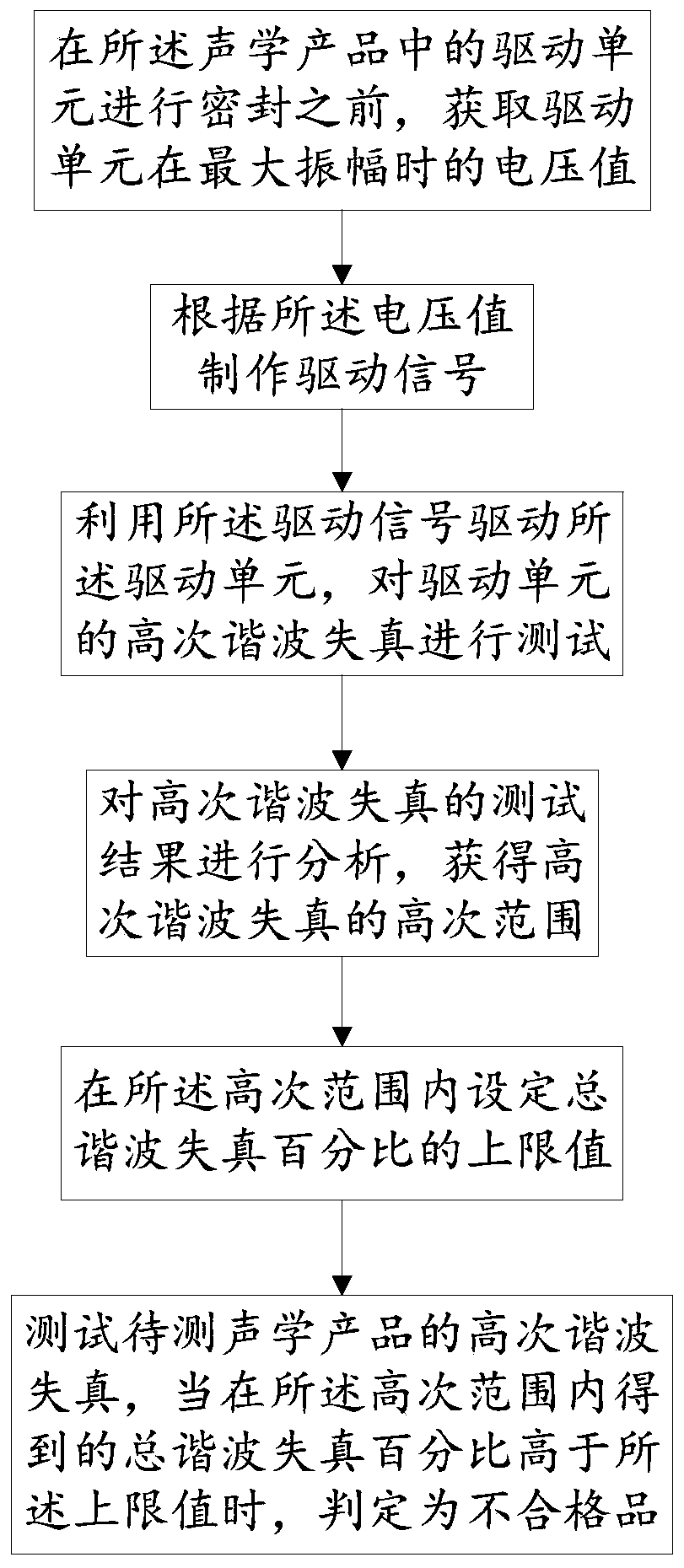

[0064] Please refer to figure 1 , Embodiment 1 of the present invention is: a noise testing method for an acoustic product, which can be used for defect detection of the drive unit before the drive unit of the acoustic product is packaged, and can detect small defects. mainly includes:

[0065] S1. Before the drive unit in the acoustic product is sealed, obtain the voltage value of the drive unit at the maximum amplitude. Specifically: before the drive unit is sealed, the drive unit is tested with a continuous frequency sweep signal, and the amplitude of the drive unit is detected by the laser displacement test method, and the voltage value of the drive unit at the maximum amplitude is obtained, which can be obtained by Klippel to achieve. In this embodiment, the frequency range of the continuous frequency sweep signal is 100-2000 Hz, of course, the frequency range can also be enlarged or reduced, depending on the specific test situation. Preferably, the drive unit is teste...

Embodiment 2

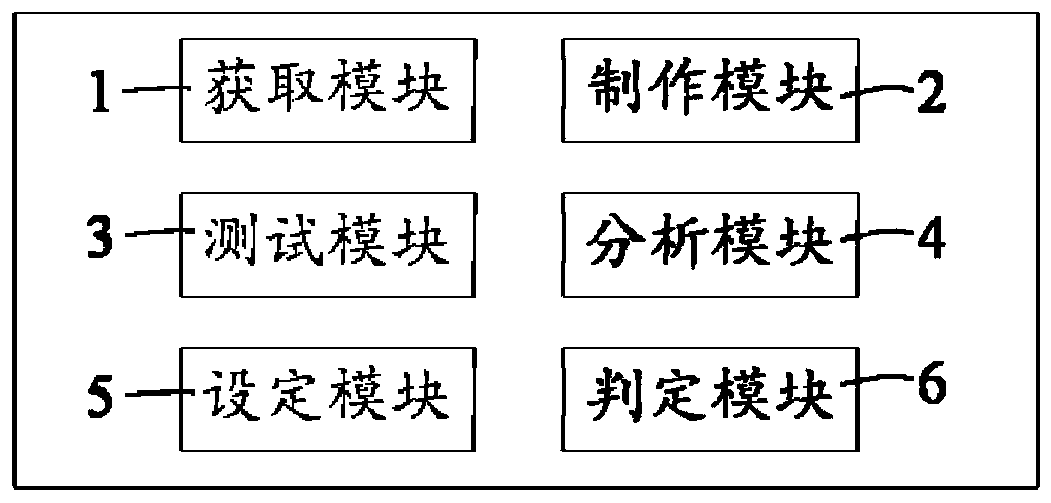

[0073] Please refer to figure 2 , Embodiment 2 of the present invention is: a noise testing system for acoustic products, corresponding to the above-mentioned method, including:

[0074] The acquisition module 1 is used to acquire the voltage value of the drive unit at the maximum amplitude before the drive unit in the acoustic product is sealed; it is specifically used to test the drive unit with a continuous frequency sweep signal, and use laser displacement The test method detects the amplitude of the drive unit, and obtains the voltage value of the drive unit at the maximum amplitude; the frequency range of the continuous frequency sweep signal used by the acquisition module 1 is 100-2000Hz;

[0075] Production module 2, for producing a driving signal according to the voltage value; preferably, for producing a driving signal using a ratio greater than or equal to 70% of the voltage value as the voltage value of the driving circuit; further preferably using the voltage val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com