Moving-type full-surrounding steel ladle hot-repairing dedusting hood device

A technology of dust hood and full enclosure is applied in the field of mobile fully enclosed ladle hot repair dust hood devices, which can solve the problems of high cost operation, damage to sliding nozzles, easy slag formation of ladle, etc., and achieves fast dust removal efficiency, less air leakage and clearance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

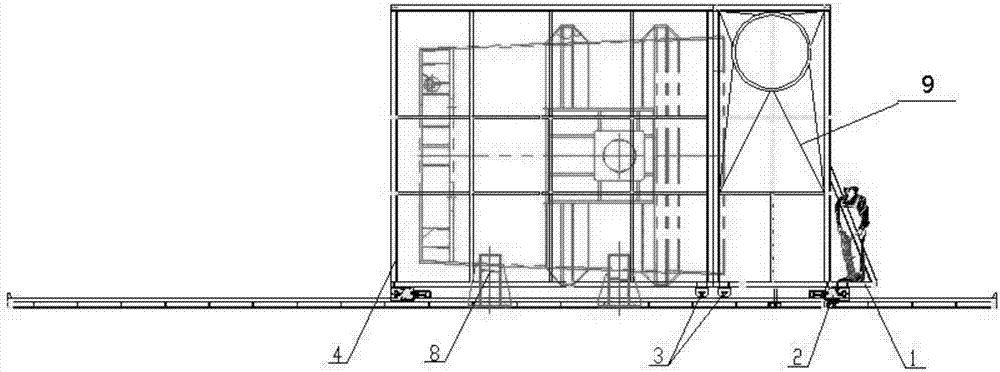

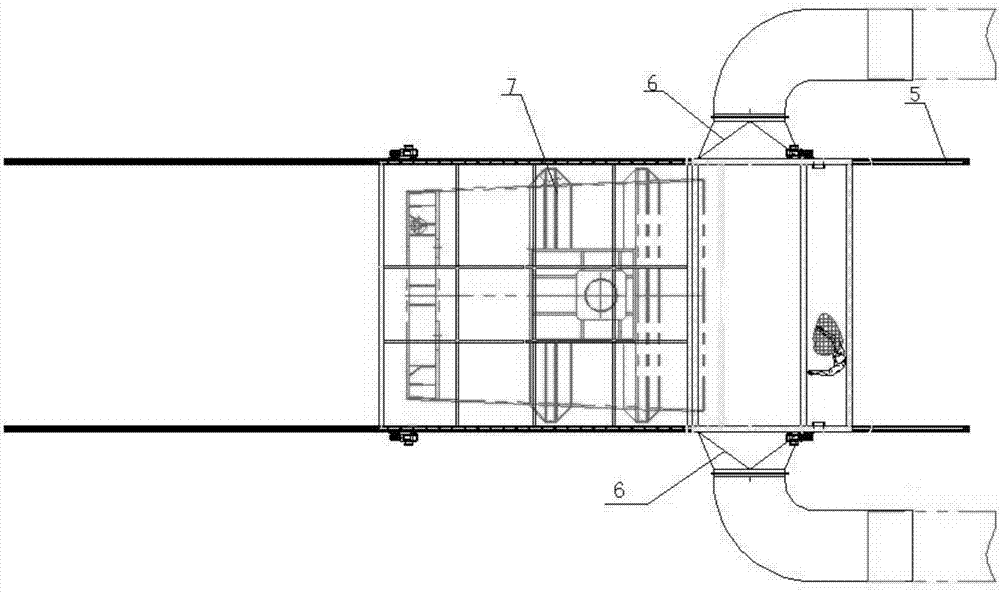

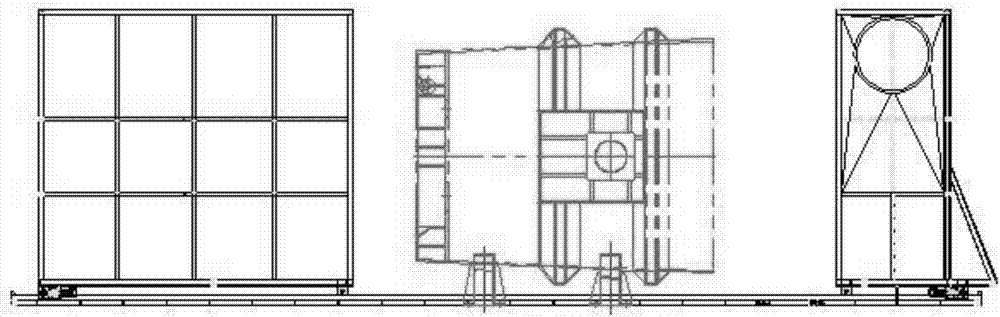

[0021] Such as figure 1 As shown, a mobile all-enclosing ladle hot repair dust removal cover device is mainly composed of a main dust removal cover 1, an auxiliary dust removal cover 4 and a track device 5. Main dust removal cover 1 is installed on driving wheel 2 and driven wheel 3, and main dust removal cover 1 contains two driving wheels 2 and two driven wheels 3, one on one side, guarantees synchronous movement, prevents wheel derailment. The main dust removal cover 1 is installed on the ladle mouth side, and the heat insulation layer laying surface 9 inside the main dust removal cover 1 is laid with a heat insulation layer to prevent the operators on the main dust removal cover 1 from high temperature radiation. The main dust removal cover 1 is provided with an operating platform, which is convenient for workers to operate. Main dust removal cover 1 is all insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com