Glass horizontal type linear transfer table and control method thereof

A conversion table and glass technology, applied in glass production, furnace, electric charge control, etc., can solve the problems of large machine footprint, only suitable for small-sized glass, complex positioning mechanism, etc., achieve high degree of automation, save cost resources, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the drawings and embodiments:

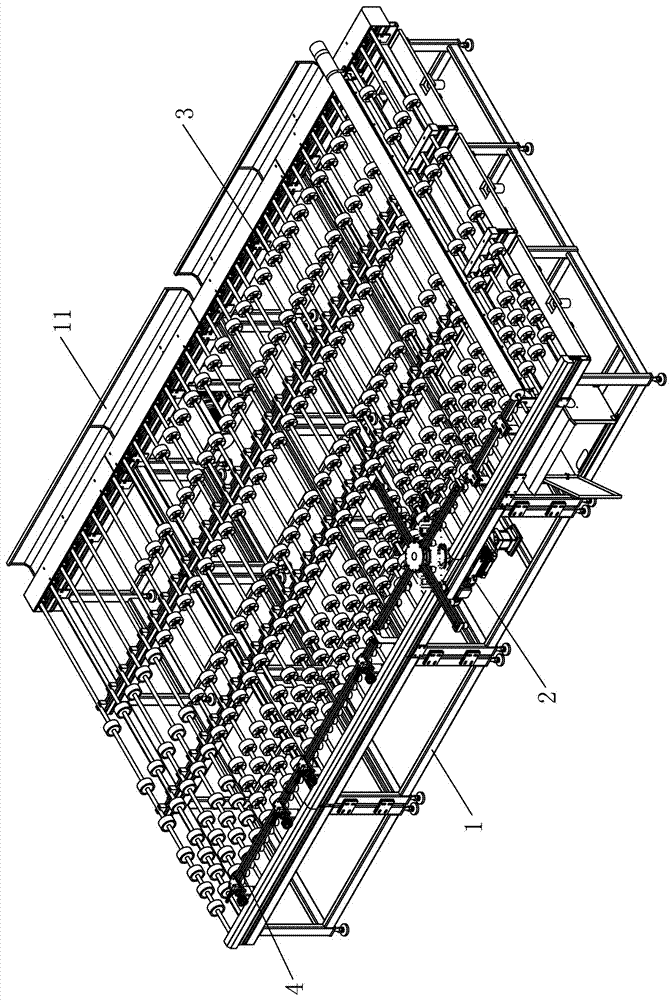

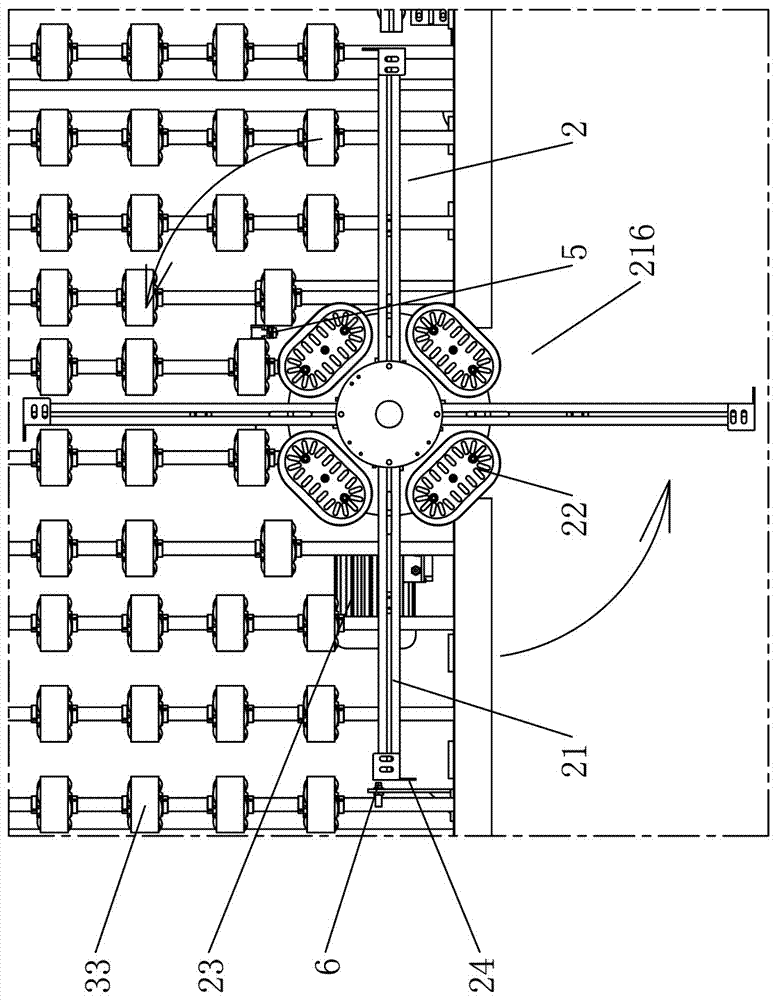

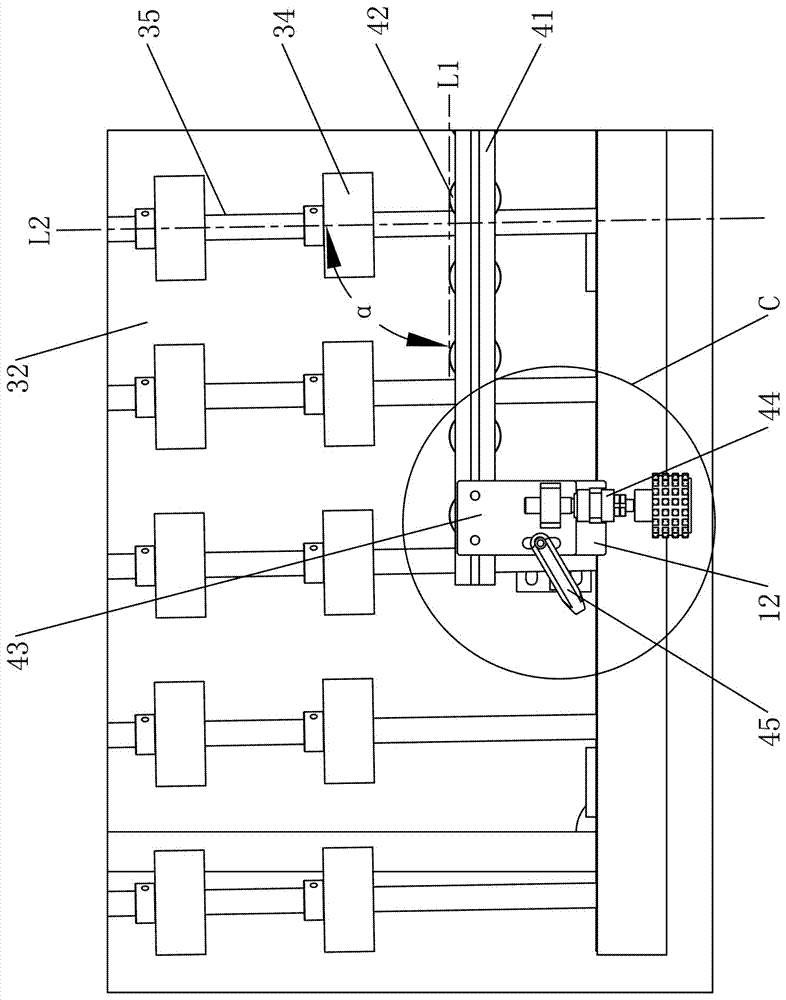

[0041] See figure 1 with figure 2 As shown, a glass horizontal linear conversion table includes a platform assembly 1 and a supporting and conveying roller set 3 and a side guide wheel set 4 arranged on the platform assembly 1 and a side guide wheel set 4 It is arranged in a straight line along the glass transmission direction and is located on the side above the supporting and conveying roller set 3. The platform assembly 1 is also provided with a glass lifting angle for lifting a corner of the glass and assisting the glass rotation and reversing The driving device 2, the glass linear in-position detection element 5 for detecting the in-position of the glass, and the glass rotation in-position detection element 6 for detecting the rotation position of the glass lifting rotation driving device 2. The stand assembly 1 is composed of a plurality of stands, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com