Automatic intelligent all-direction transferring platform parking system and method for parking garage

An automatic parking and parking system technology, applied in the field of robotics, can solve the problems of hindering the passage of transfer vehicles, sagging and deforming of the comb-tooth bearing pipe, and unfavorable parking garage space, so as to improve the parking density and space utilization, and reduce the width of the aisle. demand, the effect of improving the efficiency of parking and retrieval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

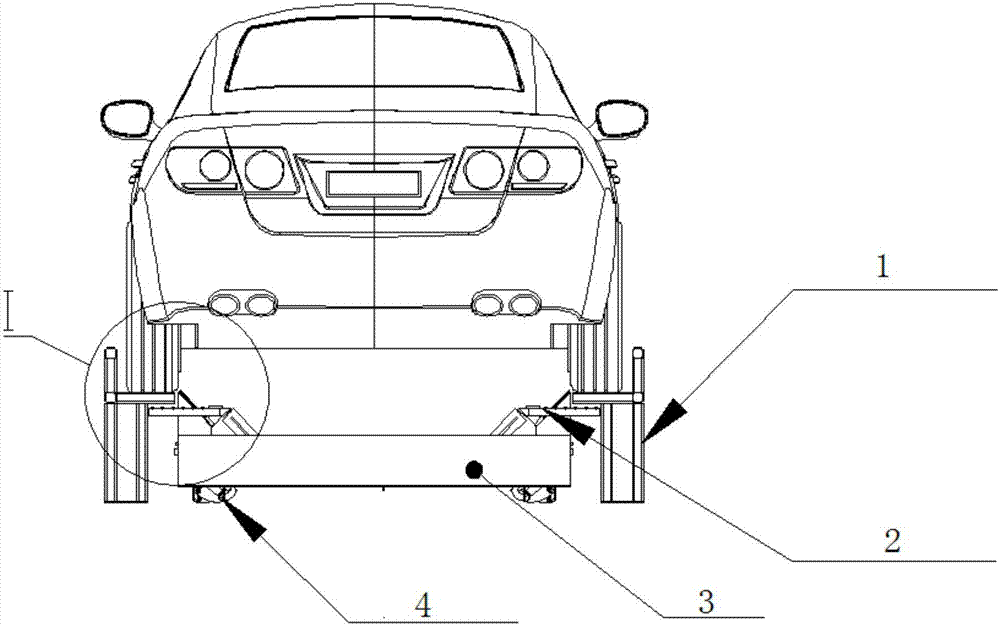

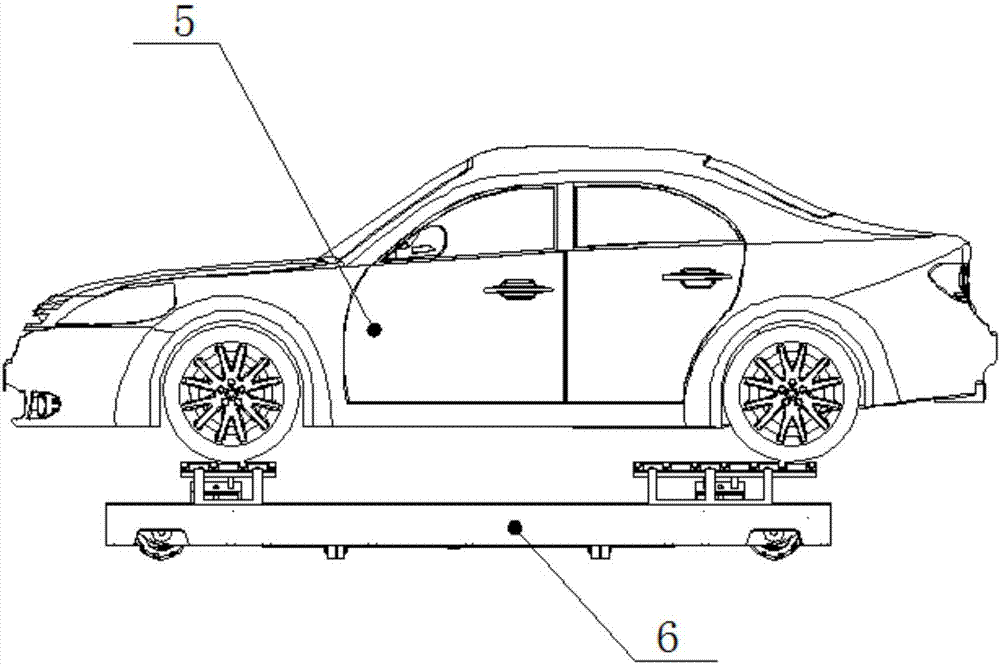

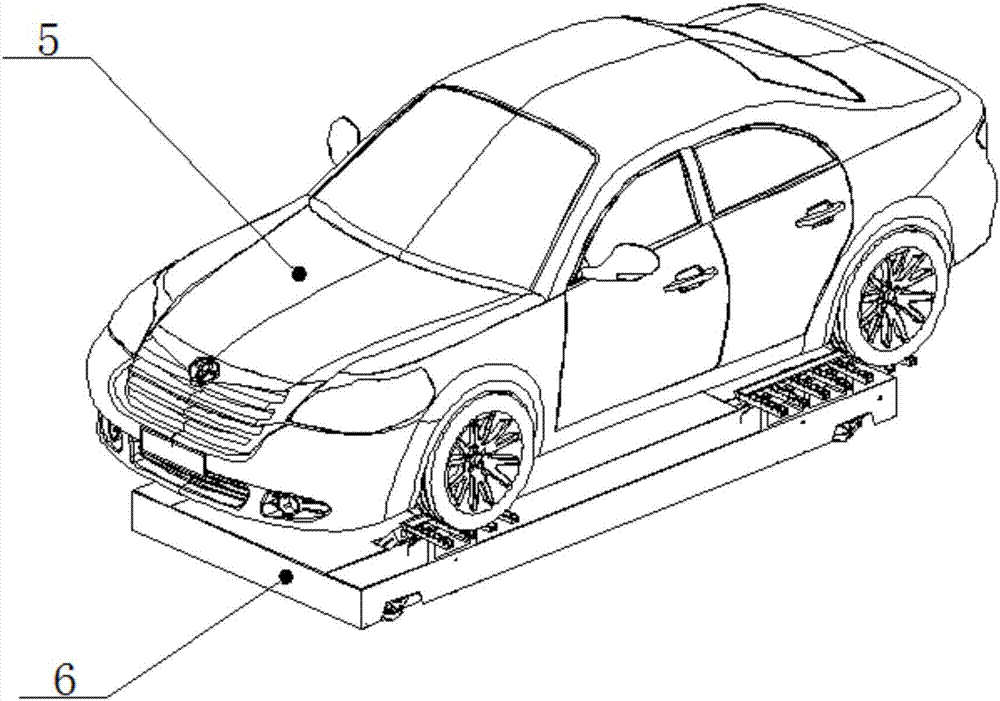

[0042] Such as Figure 1 ~ Figure 3 Shown is a parking system for an intelligent omni-directional transfer platform for an automatic parking garage. The comb teeth of the garage entrance comb frame or the parking space comb frame 1 are staggered; the bottom of the car body 3 is provided with a mecanum wheel 4, and the vehicle-mounted comb frame 2 and the car body 3 are connected by a lifting mechanism, and the lifting mechanism ( Figure 4 ~ Figure 6 ) includes a frame 13 inclined to the outside of the car body 3, on which a pair of inclined guide rails 10 and a horizontal guide plate 11 moving up and down along the guide rail 10 are provided on the frame 13, and the upper and lower sides of the guide plate 11 are connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com