Method for strengthening lithium aluminum silicon glass

A lithium-aluminum-silicon and glass technology, applied in the field of strengthening process, can solve the problems of weak scratch resistance and scratch tolerance, decline of glass strengthening effect, low glass strength, etc., so as to improve glass strength, increase strengthening efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

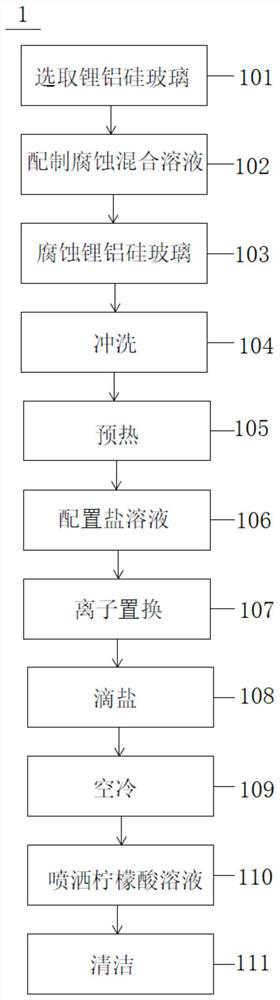

[0042] see figure 1 , which shows a schematic flow chart of the steps of the strengthening method of lithium-aluminosilicate glass according to an embodiment of the present application; as shown in the figure, the strengthening method 1 of lithium-aluminosilicate glass includes the following steps 101 to 111. in:

[0043] Step 101: Select lithium aluminum silicate glass. The mass percent content of each component in the selected lithium aluminum silicate glass is: silicon dioxide (SiO 2 ) is 58-70%, aluminum oxide (Al 2 o 3 ) is 13-20%, lithium oxide (Li 2 O) is 3-7%, sodium oxide (Na 2 O) is 8-12%, potassium oxide (K 2O) is 0.5-5%, magnesium oxide (MgO) is 0.5-2%, calcium oxide (CaO) is 0.5-2%, iron oxide (Fe 2 o 3 ) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com