Heat engine based on shape memory alloy driving

A memory alloy and drive mechanism technology, applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power. Energy cost, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme and working principle of the present invention will be described in detail below in conjunction with the drawings and embodiments.

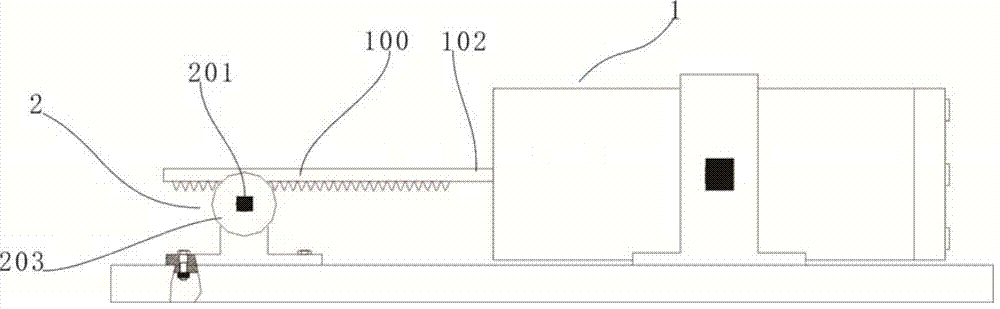

[0026] Such as figure 1 As shown, the heat engine driven by shape memory alloy includes a driving mechanism 1 and a transmission mechanism 2. The driving mechanism 1 drives the rack 100 to reciprocate through the push rod 10, so that the rack 100 drives the transmission shaft 201 of the transmission mechanism 2 to rotate. .

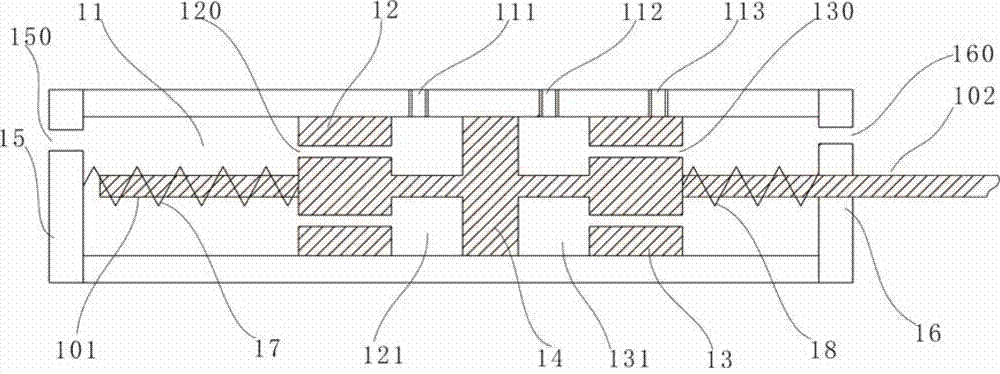

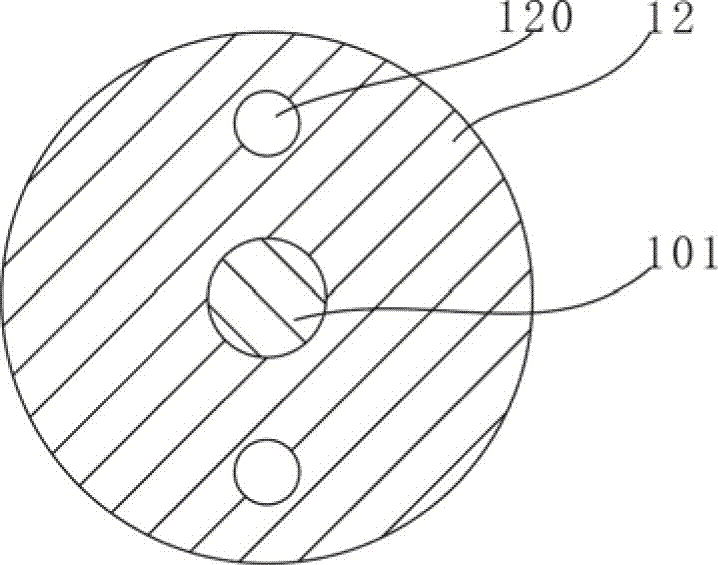

[0027] Such as figure 2 As shown, the driving mechanism 1 includes a hollow valve cavity 11, a piston 14 sliding left and right along the inner wall of the valve cavity 11 is arranged in the valve cavity 1, and a push rod is fixed on the piston 14, specifically: a first push rod is respectively arranged on the left and right sides of the piston 14 101 and the second push rod 102, wherein the second push rod 102 passes through the right end cover of the valve chamber 1, that is, the second end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com