Control system and method for protecting emulgator

A technology of control system and emulsifier, which is applied in the field of control system for protecting emulsifier, can solve problems such as ammonium nitrate decomposition, emulsifier explosion, etc., and achieve the effect of solving high-speed collision, high degree of automation, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

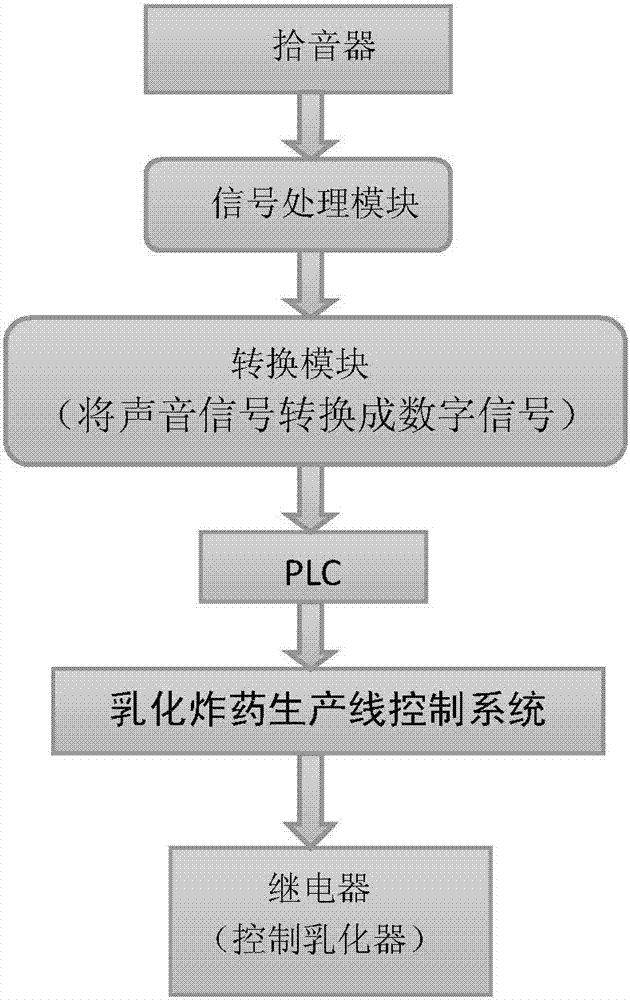

[0025] refer to figure 1 and figure 2 , the present invention adopts sound pickup, signal module, conversion module and emulsified explosive production line control system to link the internal operation of the emulsifier, that is, the operation of the bearing, through the PLC program. Compared with the implementation scheme of the prior art, the real-time processing is possible, the real-time response automation degree is higher, and the safety performance is also stronger.

[0026] In the prior art, the operation of the emulsifier is controlled manually. When the bearing of the emulsifier fails, there is no way to control the collision between the rotor and the stator of the emulsifier. The purpose of the invention is to prevent the rotor and stator of the emulsifier from colliding with each other. By identifying the sound frequency of the bearing when it is normal and the sound frequency when it is abnormal, the control system of the emulsion explosive production line can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com