Tape transport mechanism of banknote sorting and automatic bundling machine

A technology for automatic strapping and banknote sorting, which is applied in the field of machinery for packaging items or materials. It can solve the problems of unsatisfactory adjustment of strapping, unsmooth connection, and complicated mechanism, so as to achieve light and simple movements, smooth belt movement, and simplified Effects out of frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

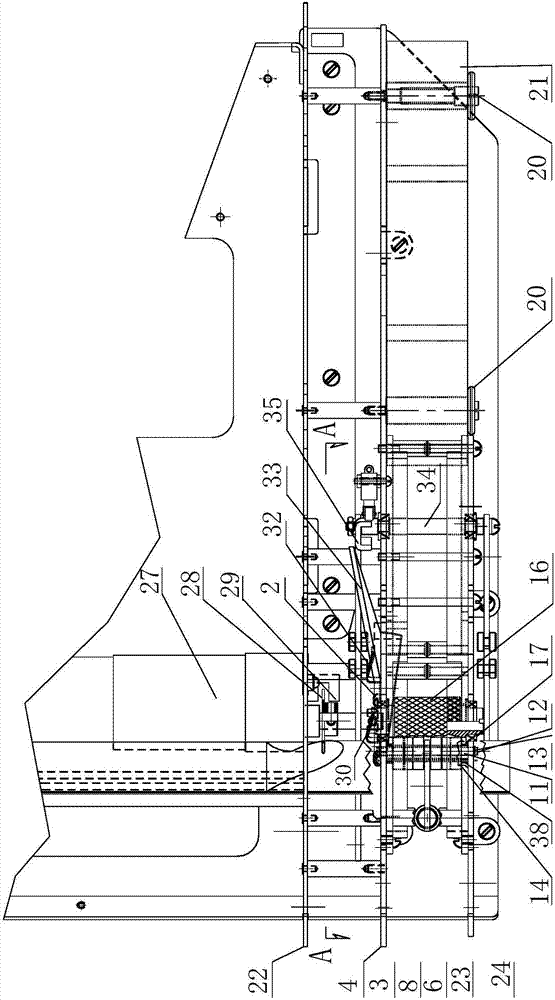

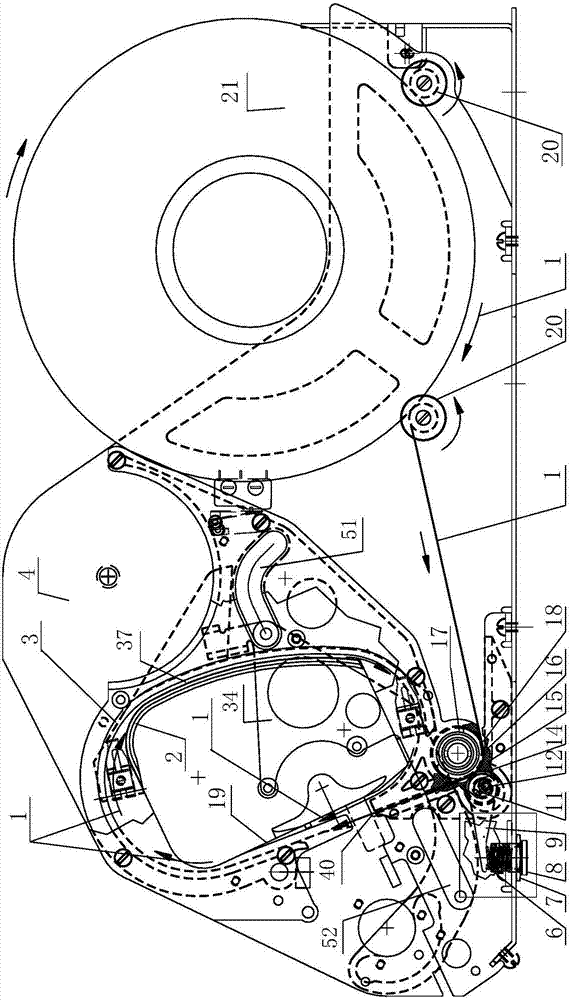

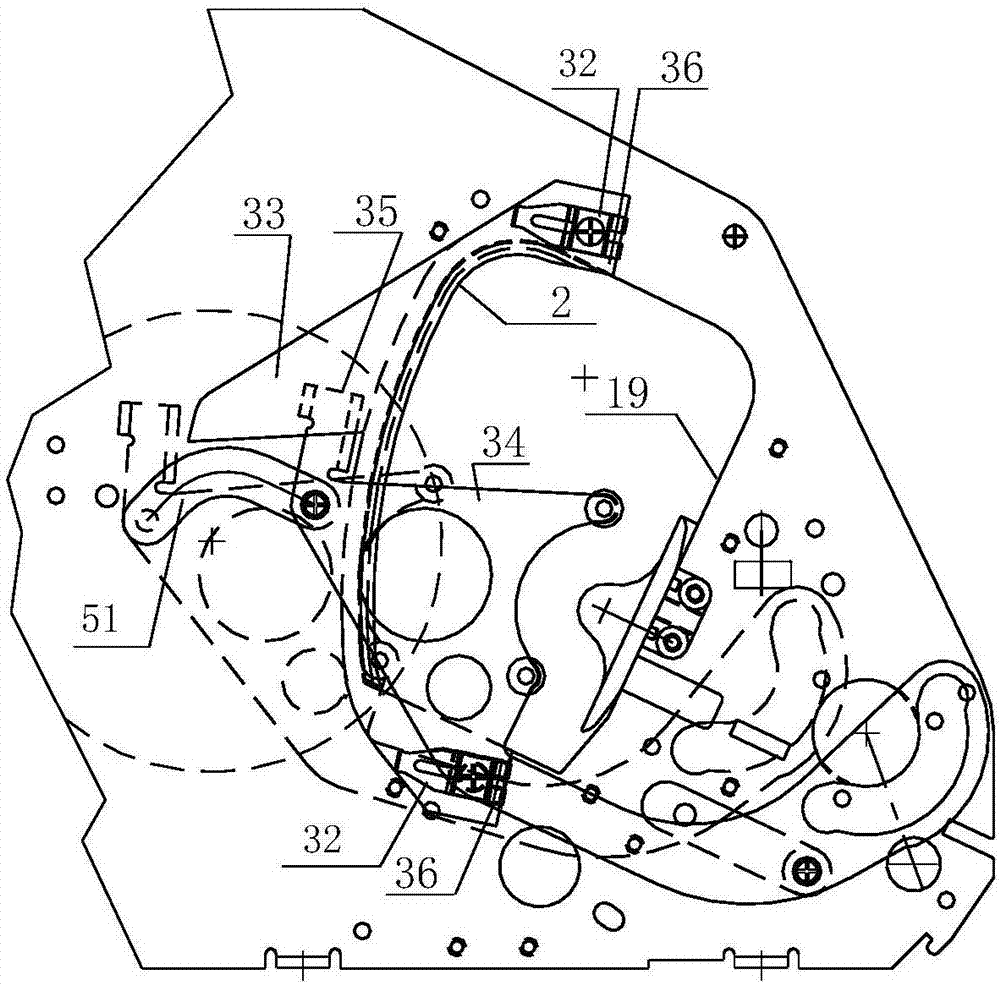

[0022] The specific implementation will be described in detail below in conjunction with the accompanying drawings: Figure 1 to Figure 5 In one embodiment of the present invention shown, a kind of banknote clearing and sorting automatic binding machine belt transport mechanism includes the right side panel 22 of the automatic binding machine frame for clearing and sorting, the binding inner panel 4, the binding outer panel 24, the pressing Banknote rack 34, described frame right side plate 22, tie handle inboard plate 4, tie handle outer plate 24 are provided with same money outlet hole 19, described banknote pressing frame 34 and tie handle inner board and tie handle outer plate The curved guide groove 51 and the straight guide groove form the mobile pair 52, which is characterized in that there is also a strap forming cavity and a strap drive mechanism, wherein:

[0023] The binding belt forming cavity contains a guide belt inner frame 3, a guide belt outer frame 23, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com