Mass spectrometry system and working method thereof

一种质谱分析、质谱仪的技术,应用在分析材料、通过电磁手段进行材料分析、粒子分离管等方向,能够解决无法保证分析灵敏度和重复性、易挥发、无法实现高通量分析等问题,达到有利于离子化、消除干扰、保障灵敏度和重复性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

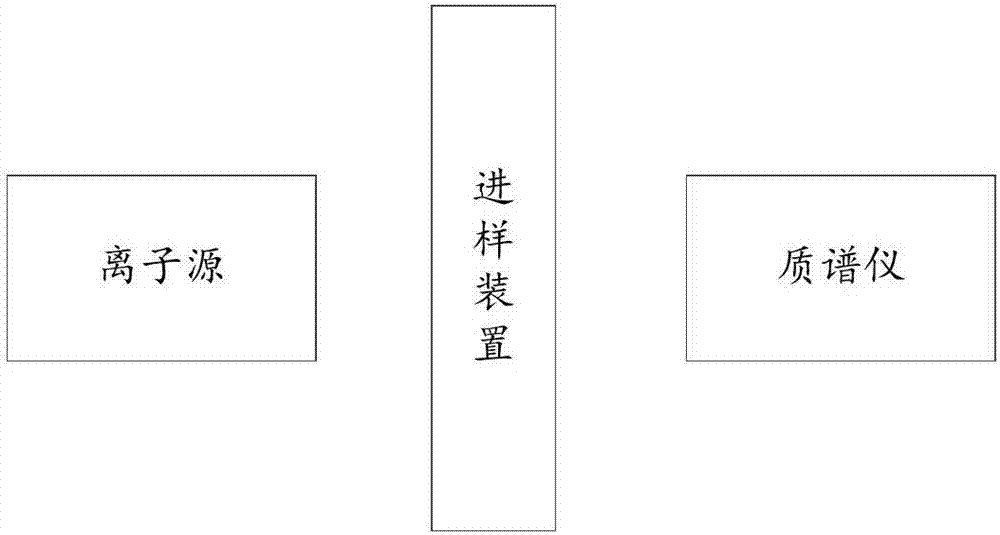

[0031] figure 1 Schematically provides a simplified structural diagram of the mass spectrometry system of the embodiment of the present invention, as figure 1 As shown, the mass spectrometry system includes:

[0032] An ion source and a mass spectrometer, the ion source and the mass spectrometer are respectively arranged on both sides of the sampling device;

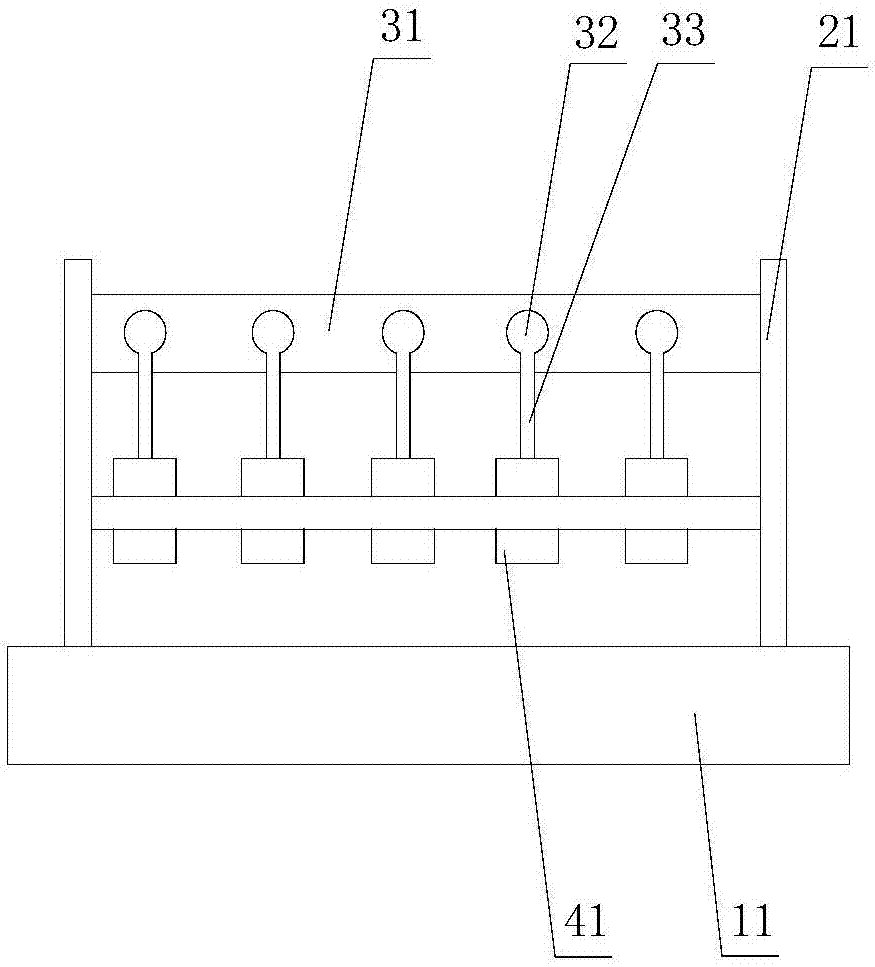

[0033] figure 2 Schematically provides a simplified structural diagram of the sampling device of the embodiment of the present invention, as figure 2 As shown, the sampling device includes:

[0034] Guide rail 11; said guide rail is arranged horizontally

[0035] Support 21, the support is suitable for moving horizontally on the guide rail;

[0036] The carrier 31, the carrier is vertically arranged, and the left and right ends are fixed on the bracket, and the carrier is made of hydrophobic material;

[0037] At least two conveying parts, the conveying part adopts hydrophilic material, including a first part 32 ...

Embodiment 2

[0045] The mass spectrometry system of the embodiment of the present invention is different from Embodiment 1 in that:

[0046] 1. No more through-holes are provided on the carrier.

[0047] 2. The guide rail is arranged vertically, the upper and lower ends of the carrier are fixed on the bracket, and the first part is arranged on the carrier from top to bottom. By moving the carrier up and down, different first parts are respectively located between the ion source and the mass spectrometer.

Embodiment 3

[0049] The mass spectrometry system of the embodiment of the present invention is different from Embodiment 1 in that:

[0050] Cut out rectangular filter paper, and there are multiple band-like structure filter paper connected with the rectangular filter paper on the side of the rectangular filter paper; print paraffin on the rectangular filter paper, but leave a number of circular areas on the rectangular filter paper, and the circular areas are connected with the bands. The connecting part of the filter paper with the shape structure is reserved, and no paraffin is printed in these reserved areas; the circular area is used as the first part, and the area where the paraffin is printed is used as the carrier for the first part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com