Coarse fiber cookie and manufacturing method thereof

A technology of crude fiber and cookies, which is applied in the field of biscuits and its production process, can solve the problems that biscuits cannot meet people's needs, and achieve the effects of promoting gastrointestinal motility, facilitating defecation, and crispy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A crude fiber cookie, including the following raw materials in parts by weight: 150 parts of flour, 20 parts of oats, 15 parts of flaxseed, 10 parts of egg liquid, 75 parts of butter, 35 parts of dried cranberries, 20 parts of fresh milk, 60 parts of sugar share.

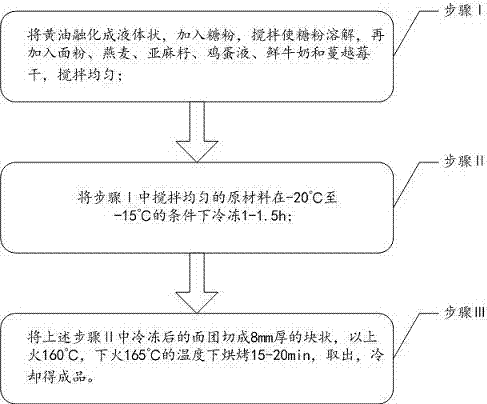

[0035] The making method of described crude fiber cookie, comprises the following steps:

[0036] Step Ⅰ, melt the butter into a liquid state, add powdered sugar, stir to dissolve the powdered sugar, then add flour, oats, flaxseed, egg liquid, fresh milk and dried cranberries, and stir well;

[0037] Step II, freezing the homogeneously stirred raw materials in step I at -20°C to -15°C for 1-1.5h;

[0038] Step III: Cut the dough frozen in the above step II into 8mm thick blocks, bake at 160°C on the upper heat and 165°C on the lower heat for 15-20min, take it out, and cool to obtain the finished product.

Embodiment 2

[0040] A crude fiber cookie, including the following raw materials in parts by weight: 175 parts of flour, 25 parts of oats, 22 parts of flaxseed, 15 parts of egg liquid, 85 parts of butter, 45 parts of dried cranberries, 25 parts of fresh milk, 65 parts of sugar share.

[0041] The making method of described crude fiber cookie, comprises the following steps:

[0042] Step Ⅰ, melt the butter into a liquid state, add powdered sugar, stir to dissolve the powdered sugar, then add flour, oats, flaxseed, egg liquid, fresh milk and dried cranberries, and stir well;

[0043] Step II, freezing the homogeneously stirred raw materials in step I at -20°C to -15°C for 1-1.5h;

[0044] Step III: Cut the dough frozen in the above step II into 8mm thick blocks, bake at 160°C on the upper heat and 165°C on the lower heat for 15-20min, take it out, and cool to obtain the finished product.

Embodiment 3

[0046] A crude fiber cookie, including the following raw materials in parts by weight: 200 parts of flour, 30 parts of oats, 30 parts of flaxseed, 20 parts of egg liquid, 90 parts of butter, 50 parts of dried cranberries, 30 parts of fresh milk, 70 parts of sugar share.

[0047] The making method of described crude fiber cookie, comprises the following steps:

[0048] Step Ⅰ, melt the butter into a liquid state, add powdered sugar, stir to dissolve the powdered sugar, then add flour, oats, flaxseed, egg liquid, fresh milk and dried cranberries, and stir well;

[0049] Step II, freezing the homogeneously stirred raw materials in step I at -20°C to -15°C for 1-1.5h;

[0050] Step III: Cut the dough frozen in the above step II into 8mm thick blocks, bake at 160°C on the upper heat and 165°C on the lower heat for 15-20min, take it out, and cool to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com