Manufacturing method of special prestressed extrusion screw for solid waste granulation

A solid waste, extrusion screw technology, applied in the direction of presses, manufacturing tools, extrusion granulation of raw materials, etc., can solve the problems of solid waste damage of extrusion screws, and achieve the effect of cost saving and flexible process selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

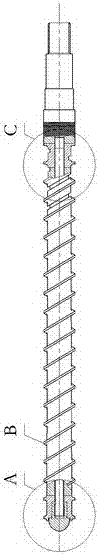

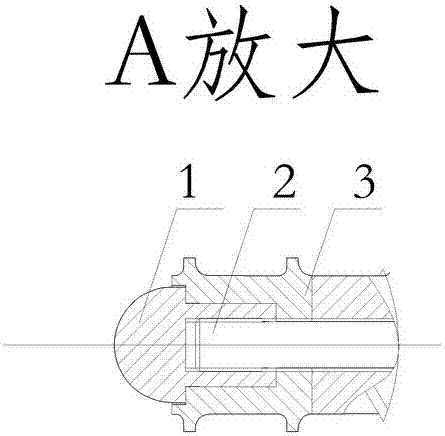

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a method for making a special prestressed extrusion screw for solid waste granulation is characterized by:

[0022] Step 1: Select 40Cr or 38 CrMoAl or 42CrMo forgings to make mandrel Ⅰ2 and mandrel Ⅱ5, connect mandrel Ⅰ2 and mandrel Ⅱ5 after rough turning and tempering, and finish car mandrel Ⅰ2 based on the bearing position of mandrel Ⅱ5 to ensure two The concentricity of the

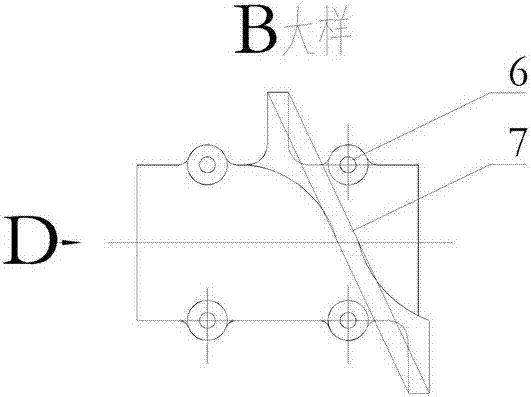

[0023] Step 2: Precision investment casting of the spiral reamer half ring 7, the material is preferably ZG270-500, the casting is quenched and tempered after annealing, the hardness is HRC25-32, and the two spiral reamer half rings 7 are locked by high-strength bolt assembly 6 after drilling .

[0024] Step 3, the spiral reamer ring assembly 4 is threaded into the mandrel I2 in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com