Thin-walled workpiece milling chatter restraining method

A technology for milling chatter and thin-walled parts, which is applied in the direction of manufacturing tools, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of poor rigidity, small stable range, poor practicability, etc., and achieve high-speed chatter-free The effect of milling, improving the stable domain, and the range of reliable parameter selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

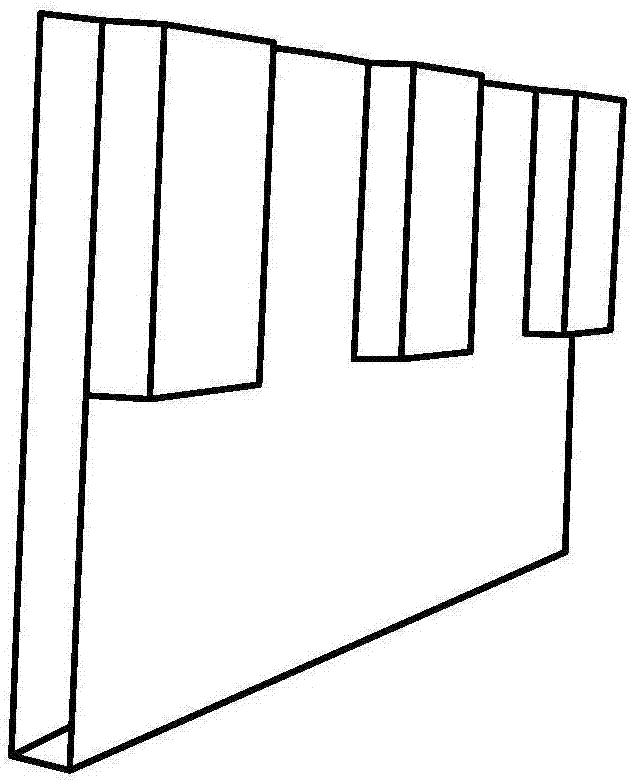

[0023] Example 1: The size of the thin plate is 115mm×36mm×3.5mm, the material is aluminum alloy 7075, the modulus of elasticity is 71GPa, and the density is 2810kg / m 3 , Poisson's ratio is 0.33; the cutting tool is a cemented carbide milling cutter with 2 blades, a diameter of 15.875 mm, and a helix angle of 30 degrees. The tool extension length is 78 mm.

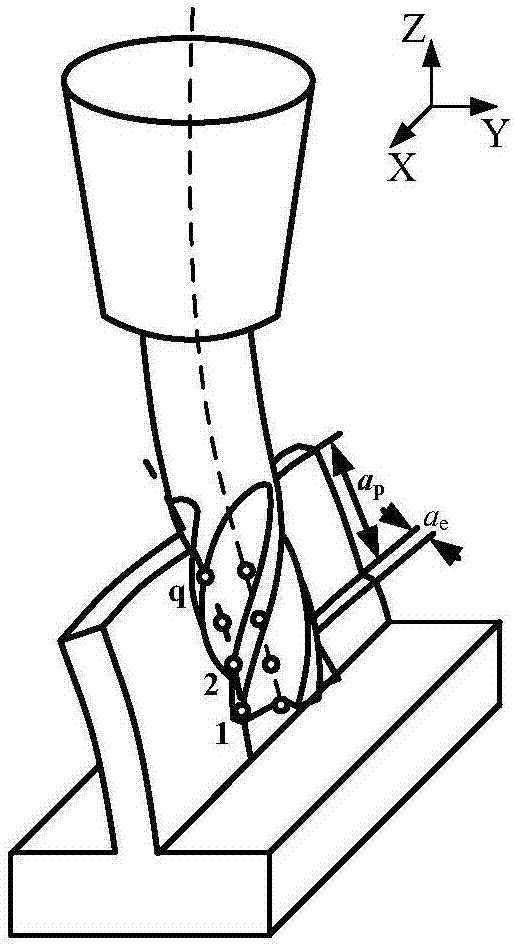

[0024] 1. Utilize the milling dynamics model of the thin-walled parts deformed by the cutting tool and the workpiece, divide the cutting tool and the workpiece into 40 microelements along the axial direction, that is, q=41; establish the milling kinetic equation at each microelement respectively, and Find the dynamic milling force:

[0025]

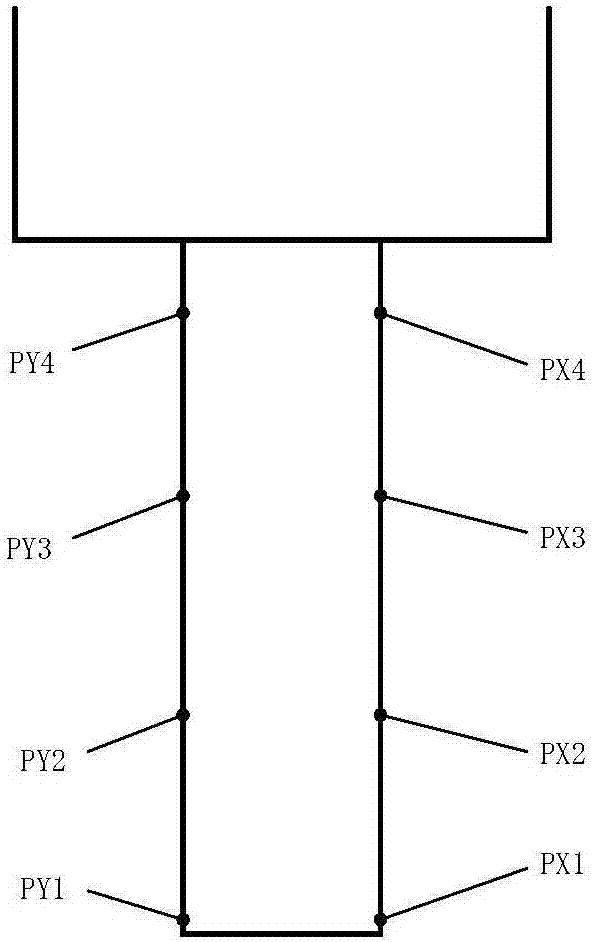

[0026] 2. After installing the tool to the spindle of the machine tool, use the multi-point percussion test method and linear interpolation method to measure the tool feed direction and the modal parameters perpendicular to the feed direction; ζ m,t,x , ζ m,t,y Indicates the damp...

Embodiment 2

[0046] Example 2: The size of the thin plate is 100mm×40mm×4.5mm, the material is aluminum alloy 7075, the modulus of elasticity is 71GPa, and the density is 2810kg / m 3 , Poisson's ratio is 0.33; the cutting tool is a cemented carbide milling cutter with 2 blades, a diameter of 15.875 mm, and a helix angle of 30 degrees. The tool extension length is 78 mm.

[0047] 1. Utilize the milling dynamics model of the thin-walled parts deformed by the cutting tool and the workpiece, divide the cutting tool and the workpiece into 30 microelements along the axial direction, that is, q=31; establish the milling dynamic equation at each microelement respectively, and Find the dynamic milling force:

[0048]

[0049] 2. After installing the tool to the spindle of the machine tool, use the multi-point percussion test method and linear interpolation method to measure the tool feed direction and the modal parameters perpendicular to the feed direction; ζ m,t,x , ζ m,t,y Indicates the damp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com