Revolution sprayer assembly for 3D printer

A technology of 3D printers and nozzle components, applied in the field of 3D printing, can solve the problems of affecting printing efficiency and increasing the complexity of programming, and achieve the effect of simplifying the programming process and shortening the printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

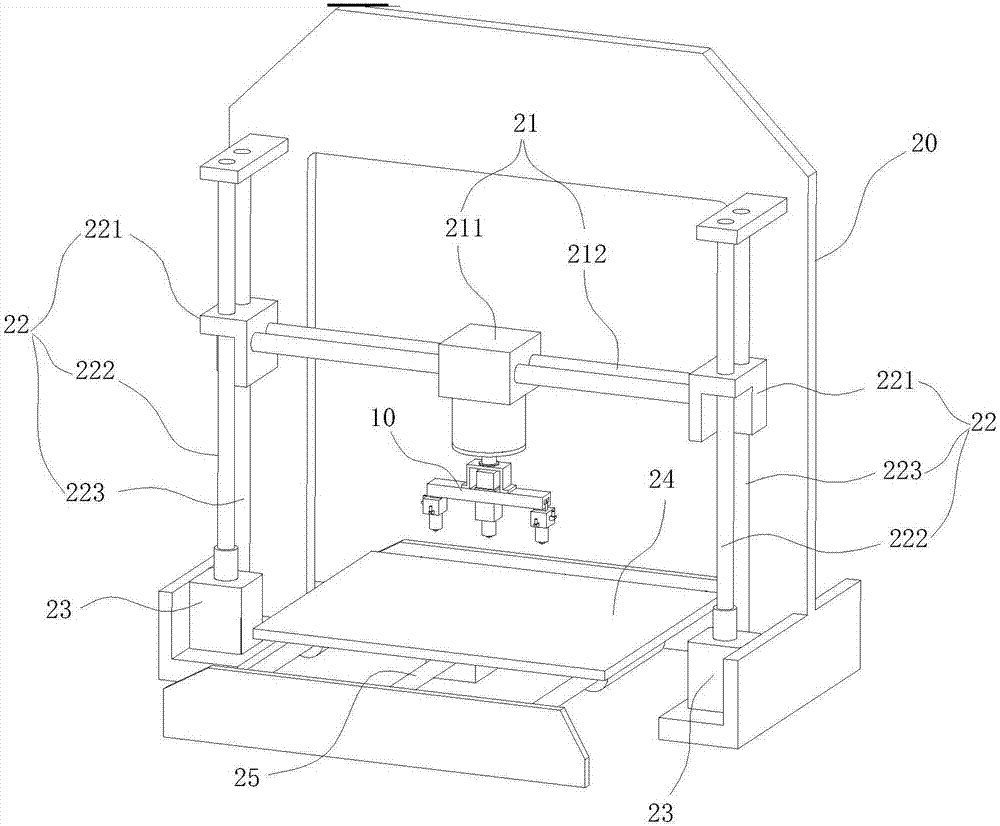

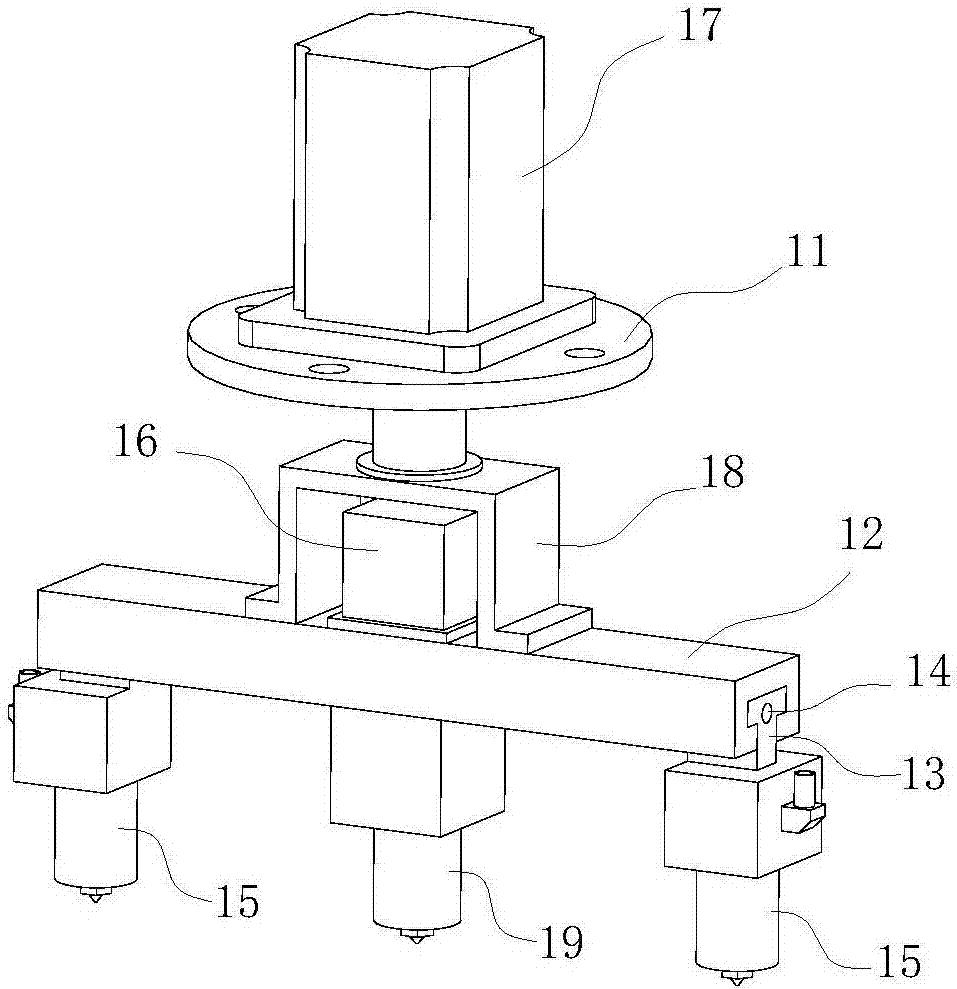

[0017] Such as figure 1 , 2 , 3, a 3D printer includes a rotary nozzle assembly 10, the rotary nozzle assembly 10 includes a connecting portion 11 and a rotary portion 12, the connecting portion 11 is used to connect the nozzle 15 driving mechanism of the rotary nozzle assembly of the 3D printer , the turning part 12 is rotatably arranged on the connecting part 11 along the vertical axis, and at least two sliders 13 are arranged on the turning part 12, and each slider 13 moves along a circle centered on the turning center of the turning part 12. The radial direction of the shaped area is slidably arranged on the rotary part 12, and each slider 13 is set for synchronous and symmetrical movement with the center of rotation of the rotary part 12 as a symmetrical point; a nozzle 15 is installed on each slider 13, and The position of each spray head 15 is arranged symmetrically with respect to the center of rotation of the rotation part 12 . The rotary nozzle assembly of the 3D p...

Embodiment 2

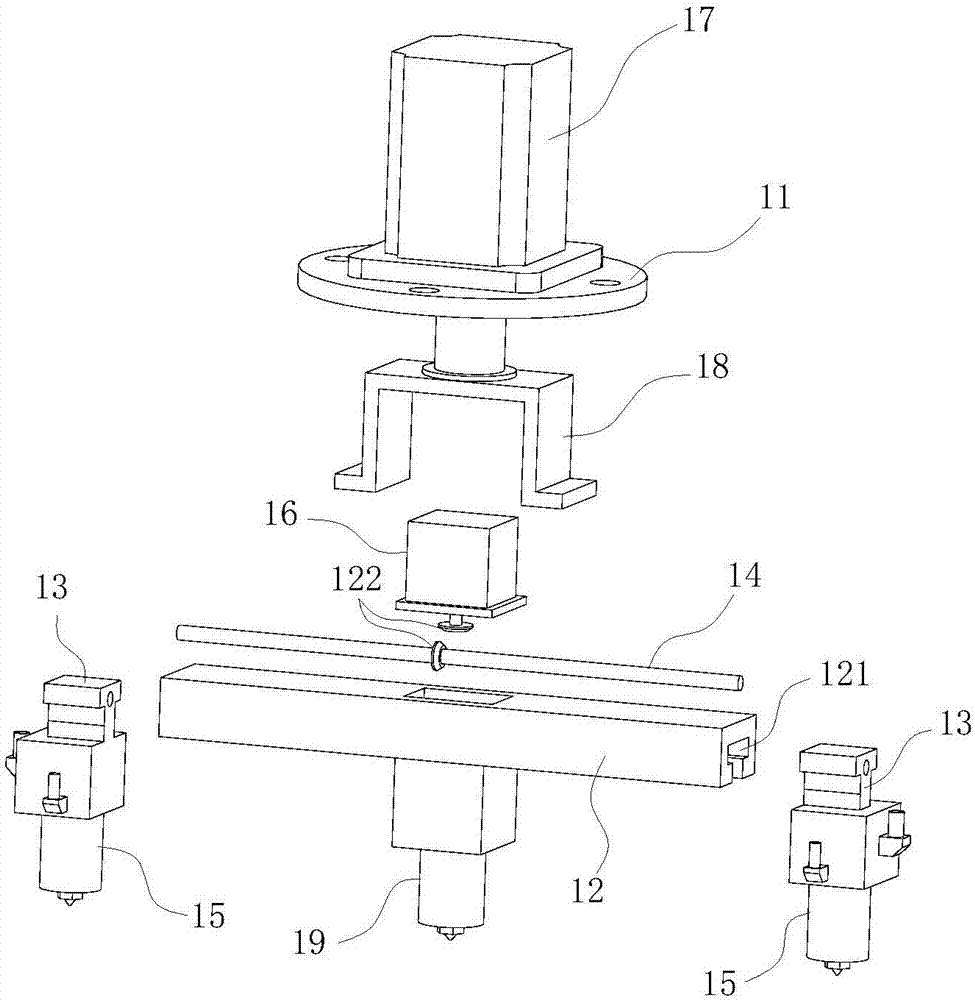

[0021] Such as figure 2 , 3 As shown, a rotary nozzle assembly 10, the rotary nozzle assembly 10 includes a connecting part 11 and a rotary part 12, the connecting part 11 is used to connect the nozzle 15 drive mechanism of the rotary nozzle assembly of the 3D printer, the rotary part 12 Rotate along the vertical axis and be arranged on the connecting part 11. At least two sliders 13 are arranged on the turning part 12, and each slider 13 is along the radial direction of a circular area with the turning center of the turning part 12 as the center. Slidingly arranged on the rotary part 12, and each slider 13 is set with the center of rotation of the rotary part 12 as a symmetrical point for synchronous and symmetrical movement; each of the sliders 13 is respectively equipped with a shower head 15, and the position of each shower head 15 is about The turning center of the turning part 12 is symmetrically arranged.

[0022] Preferably, a two-way screw rod 14 is arranged on the...

Embodiment 3

[0024] Such as Figure 4 As shown, in this embodiment, a double-link slider 13 mechanism is used to realize the synchronous movement of the two sliders 1313, including a linear motor 111, the main shaft 112 of the linear motor 111 is hinged to the two connecting rods 113, and the other ends of the two connecting rods 113 are respectively It is hinged with two sliders 1313 to convert the vertical motion of the main shaft 112 of the linear motor 111 into the horizontal motion of the slider 1313 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com