3D printing digital model sectioning and interface designing method, and application thereof

A digital model and 3D printing technology, applied in the field of 3D printing modeling, can solve the problems that no patent publications have been found, data cannot be printed correctly, and inner surface information is ignored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] A 3D printing digital model cutting and interface design method, the steps are as follows:

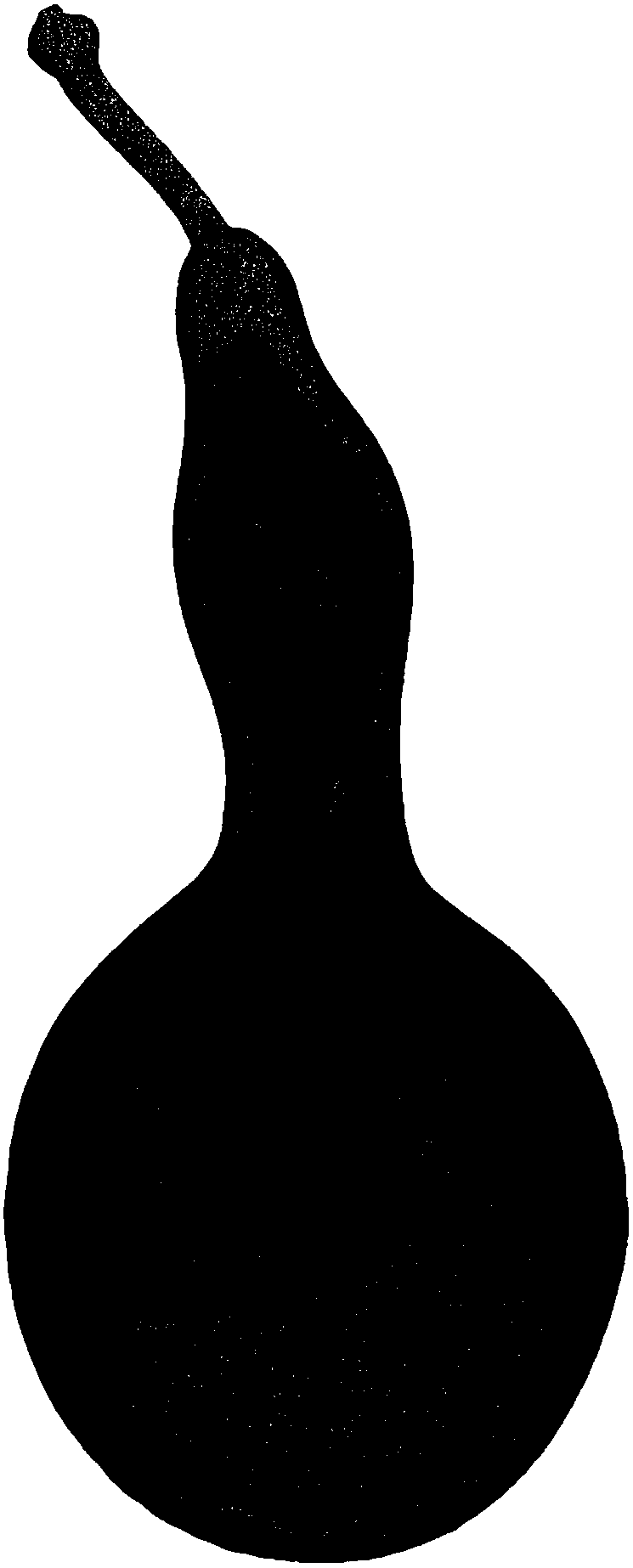

[0109] (1) Input the 3D printing digital model, specify the tangent plane by specifying the parameters of the plane equation, cut the model by using the positional relationship between the point and the plane, decompose it into different blocks, obtain the decomposed digital model, and make the original 3D printing digital model The inner surface of the model is transformed into an outer surface;

[0110] (2) If you need to decompose the model in more detail, you can repeat step (1) to cut the 3D printed digital model multiple times; after the model is cut, an interface will be added to the cut surface formed by the cut for splicing and decomposition post-digital model;

[0111] (3) Use the method of picking up triangular patches to specify the interface position on the cut surface formed by cutting the 3D printing data model, that is, click to select the triangular patch on th...

Embodiment 2

[0152] A 3D printing digital model cutting and interface design method, the steps are as follows:

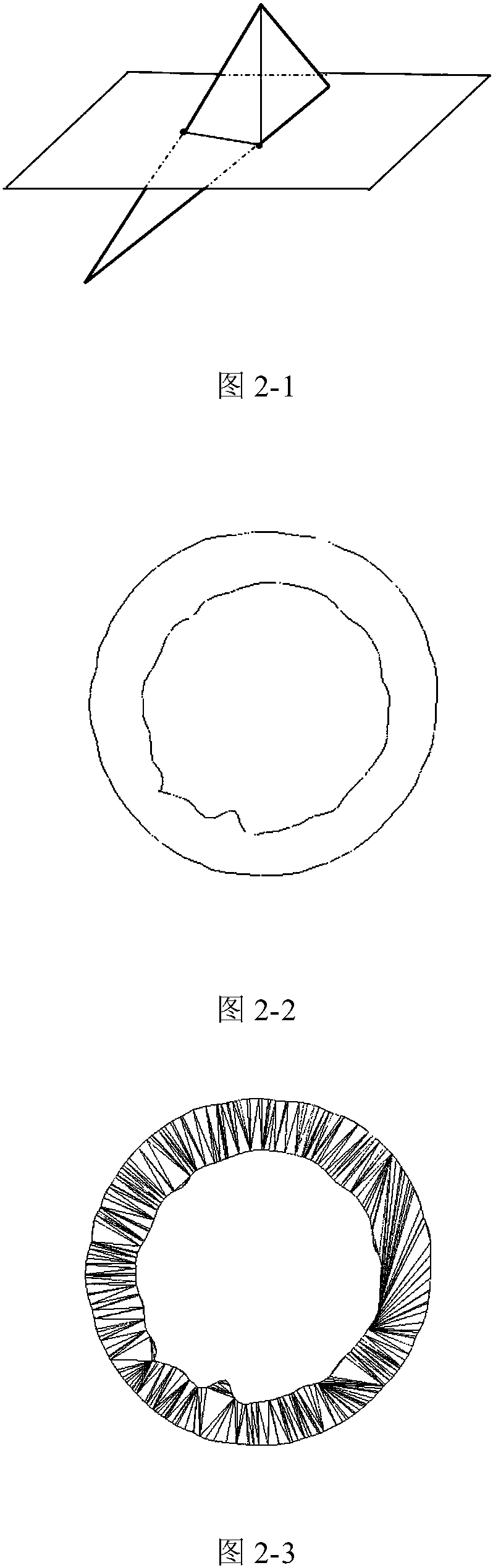

[0153] Specify the tangent plane, the tangent relationship between the tangent plane and the triangular patch is as follows Figure 2-1 As shown in , the tangent relationship between all the patches in the triangular mesh and the plane is judged, and two decomposed digital models are obtained, as well as several closed line segments on the plane. like Figure 2-2 As shown in , the scattered line segments are connected end to end to obtain a group of closed edges, and the inclusion relationship of the closed edges is judged to obtain a polygonal area surrounded by the closed edges. like Figure 2-3 As shown in , triangulation is performed inside the polygon area, and the triangulation results are added to the two decomposed digital models respectively, keeping the normal direction of the triangle patch in the decomposed digital model consistent with the outward direction of the...

Embodiment 3

[0159] A 3D printing digital model cutting and interface design method, the specific steps are as follows:

[0160] (1) Take the plane as an example to cut R 3 For digital models in space, the general form of the plane equation is as follows:

[0161] Ax+By+Cz+D=0 (1.1)

[0162] where (A,B,C) is R 3 A non-zero vector in space is called the normal vector of the plane. In order to make the expression of the equation unique, it is stipulated that (A, B, C) is a unit vector, that is, the unit normal direction.

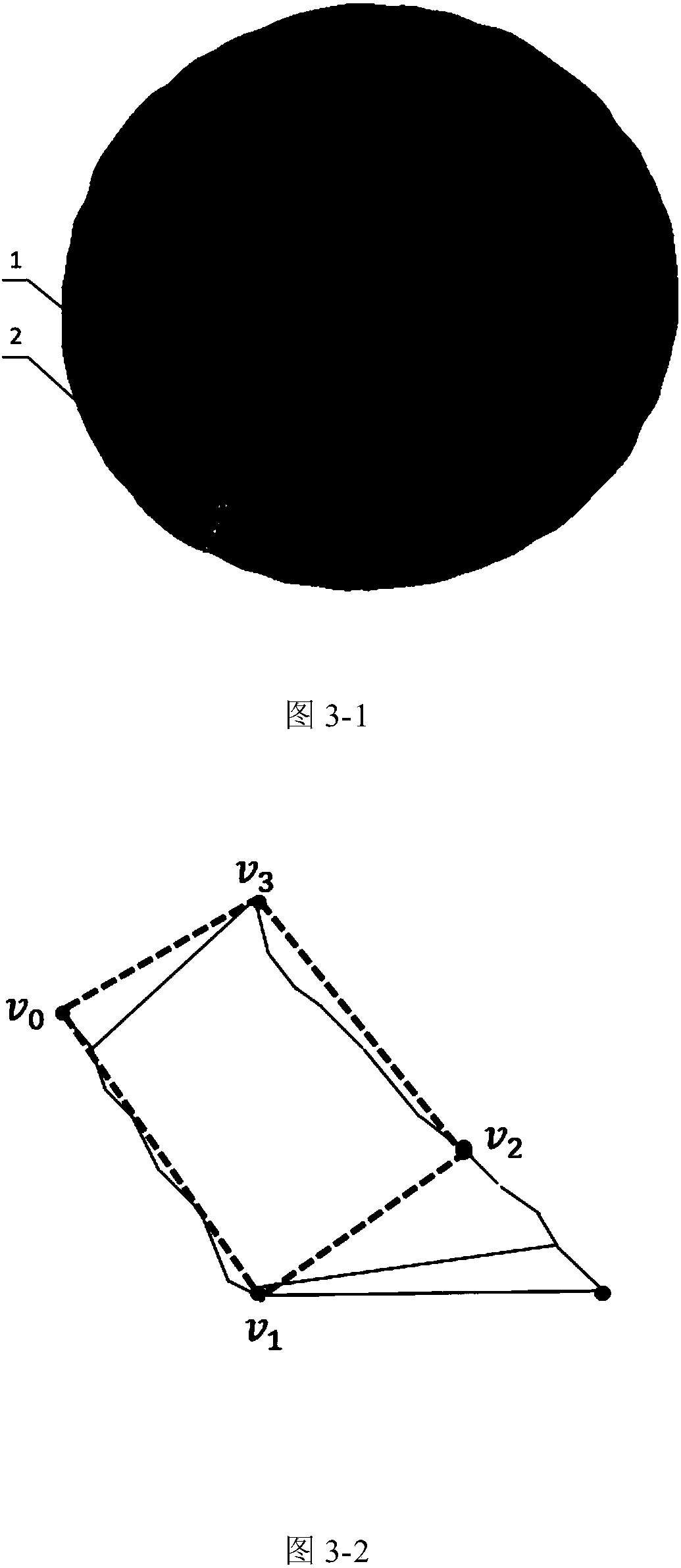

[0163] After specifying the parameters (A,B,C,D) of the plane equation, the plane equation can be uniquely determined, and the plane will be R 3 The space is divided into positive half space and negative half space. When R 3 When the digital model in space is tangent to this plane, the model is also divided into two parts, one in the positive half space and the other in the negative half space. The basic unit of a digital model is a triangle patch, which consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com