Automatic marking machine for air-conditioning refrigerant delivery pipe joints

A refrigerant and conveying pipe technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of labor-intensive and low work efficiency, and achieve the effects of labor saving, high work efficiency, and less accidents at work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

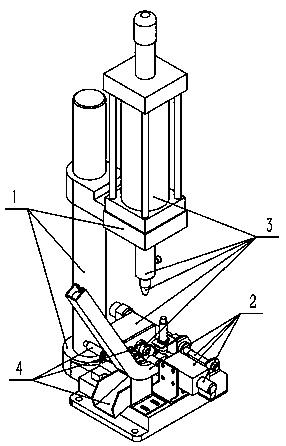

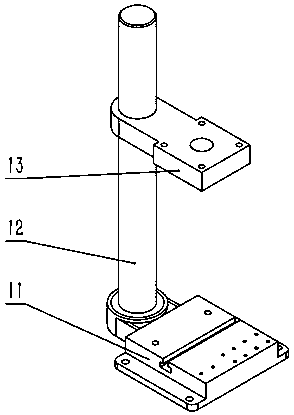

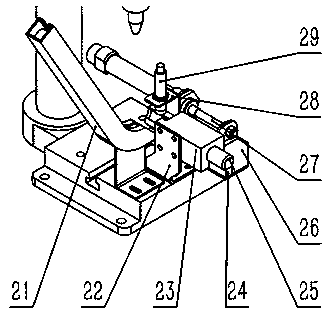

[0015] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing: see Figure 1-8 .

[0016] The air-conditioning refrigerant conveying pipe joint automatic marking machine has a frame 1, a feeding device 2, a marking device 3, a pushing device 4 and a single-chip microcomputer control system; the frame has a base 11 and is fixed on the base 11 The column 12, the cantilever 13 fixed in the middle of the column 12; the feeding device has a joint guide pipe 21 fixed on the base 11, a slide rail fixture 22, a stroke cylinder 27, and a tube fixed on the slide rail fixture 22. Slide rail 23, connecting plate 26 fixed on the piston rod free end of stroke cylinder 27, support rod 24 fixed on the connecting plate 26, push rod 25 fixed on the support rod 24, sensor fixing plate fixed on the slide rail 23 A 28, the ranging sensor A 29 that is fixed on the sensor fixed plate A 28, the push rod 25 is in the circular guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com