Discharge printing method

A technology of discharge printing and printing paste, applied in dyeing method, textile and papermaking, etc., can solve the problems of long production cycle, high defective rate, difficult to find defects, etc., and achieve the effect of saving cost and preventing color matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

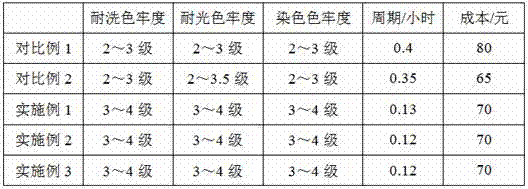

Examples

Embodiment 1

[0014] (1) Use the silk screen to make a screen version according to the required graphics;

[0015] (2) According to the volume ratio of sodium hypochlorite solution and water as 4:2, mix sodium hypochlorite solution with a pH value of 12 and water, then calculate the solid-liquid ratio g / mL as 4:30, add carboxymethyl cellulose, and Obtain printing paste after stirring evenly;

[0016] (3) Put the fabric to be dyed (the dyed fabric with a base color obtained by dyeing plants and trees) under the screen plate of step (1), then pour the printing paste of step (2) into the screen plate, and scrape the plate 3 times back and forth After starting the plate, sprinkle cornmeal on the fabric to be dyed, and then dry it for 15-25 minutes. According to the mass ratio of sulfuric acid solution and water as 1:5, mix the sulfuric acid solution with a mass concentration of 70% and water to prepare Pickling solution, use the pickling solution to wash the fabric, then wash it with water and...

Embodiment 2

[0018] (1) Use the silk screen to make a screen version according to the required graphics;

[0019] (2) According to the volume ratio of sodium hypochlorite solution to water is 5:3, mix sodium hypochlorite solution with pH value of 12 and water, then calculate the solid-liquid ratio g / mL as 5:35, add carboxymethyl cellulose, and Obtain printing paste after stirring evenly;

[0020] (3) Place the fabric to be dyed (the dyed fabric with a base color directly dyed) under the screen plate of step (1), then pour the printing paste of step (2) into the screen plate, and scrape the plate back and forth 4 After the first printing, sprinkle cornmeal on the fabric to be dyed, and then dry it for 15 to 25 minutes. According to the mass ratio of sulfuric acid solution and water as 1:5, mix the sulfuric acid solution with a mass concentration of 50% and water to prepare It is a pickling solution, and the fabric is washed with the pickling solution, then washed with water and dried in th...

Embodiment 3

[0022] (1) Use the silk screen to make a screen version according to the required graphics;

[0023] (2) According to the volume ratio of sodium hypochlorite solution and water as 4.5:2.5, mix sodium hypochlorite solution with a pH value of 12 and water, and then calculate the solid-liquid ratio g / mL as 4.5:40, add carboxymethyl cellulose, and Obtain printing paste after stirring evenly;

[0024] (3) Place the fabric to be dyed (the dyed fabric with a base color obtained by reactive dyeing) under the screen plate of step (1), then pour the printing paste of step (2) into the screen plate, and scrape the plate back and forth 4 After the first printing, sprinkle cornmeal on the fabric to be dyed, and then dry it for 15 to 25 minutes. According to the mass ratio of sulfuric acid solution and water as 1:5, mix the sulfuric acid solution with a mass concentration of 80% and water to prepare It is a pickling solution, and the fabric is washed with the pickling solution, then washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com