Dry processing method of textile coating discharge printing

A processing method and technology for dye discharge printing, applied in the field of textile printing, can solve the problems that the stability of dye discharge effect cannot be guaranteed, the effect of different color registration is inconsistent, and the definition of printing outline is affected, and the effect and stability are fully guaranteed. , Improve the cleanliness of the cloth and the definition of the printing outline, and ensure the effect of the discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Fabric: Reactive dyed black base cotton jersey

[0027] Printing paste prescription (parts by weight): UN-413 (product of a certain company) 70

[0028] Whitening agent CH (product of a certain company) 10

[0029] water 30

[0030] Process: Printing, scraping printing twice; drying at 120°C for 1 minute; continuous heat treatment machine at 150°C for 30 seconds; washing with water.

[0031] Result: whiteness level 4, soft to the touch.

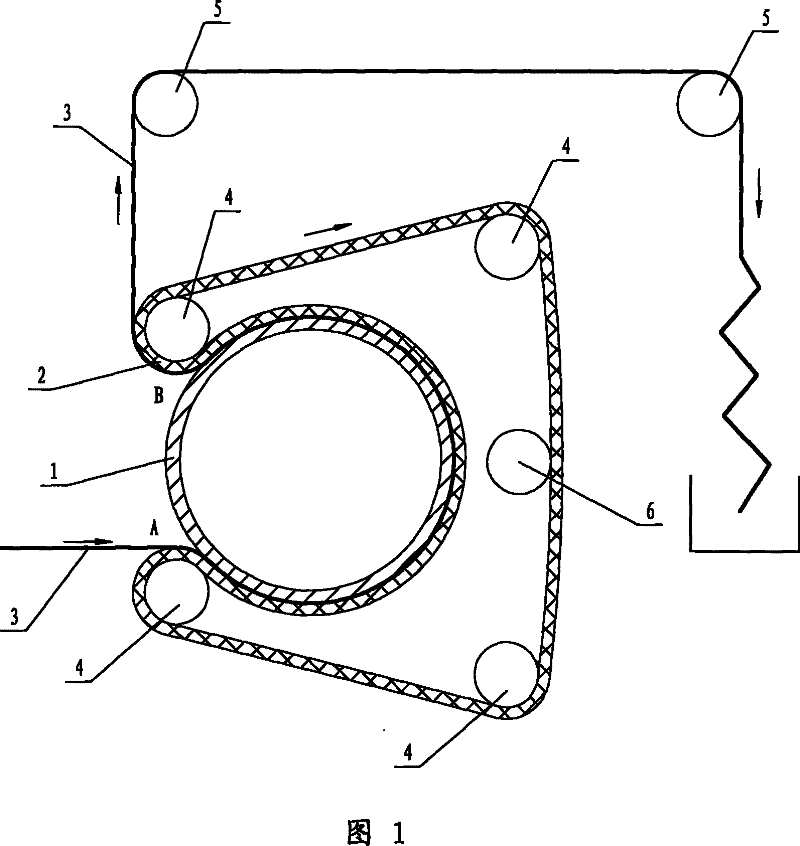

[0032] The present invention adopts continuous heat drying cylinder heat treatment machine to adopt continuous contact heat treatment (such as figure 1As shown), the heat treatment machine is composed of a rotary heat drying cylinder, a covering blanket, a guide roller, and a cloth guide roller. An airtight covering blanket 2 is closely attached to the outer wall of the heat drying cylinder 1, and its head and tail are connected. Each of the four corners in the covering blanket is provided with a guide roller 4 for supporting the c...

Embodiment 2

[0036] Fabric: Reactive dyed cotton jersey with a bright red base

[0037] Printing paste prescription (parts by weight): UN413 (product of a certain company) 75

[0038] De Colin 10

[0039] Paint yellow F-R (product of a certain company) 0.5

[0040] water 25

[0041] Process: Printing, scrape printing twice; drying at 60°C for 10 minutes; flat pressing machine at 160°C for 15 seconds; washing with water.

[0042] Result: The printed part is pure yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com