Vibration isolation device for combining high and low frequency vibration

A high-low frequency, vibration isolation technology, applied in the direction of shock absorber, shock absorber-spring combination, spring, etc., can solve the problems of poor vibration isolation effect in the resonance area and reduce the vibration isolation efficiency of the vibration isolation area, so as to reduce vibration The effect of lowering the amplitude, lowering the resonance frequency, and widening the vibration isolation frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiment of the present invention is commented as follows in conjunction with accompanying drawing:

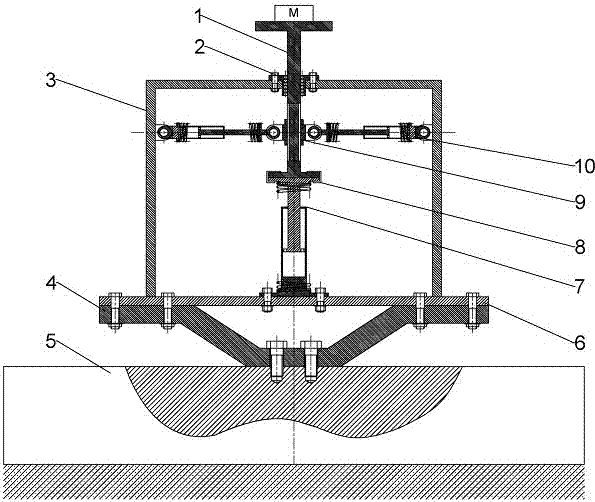

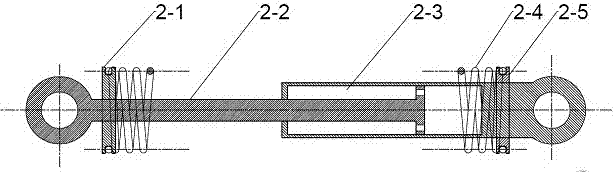

[0016] see figure 1 , a vibration isolation device that takes into account both high and low frequency vibrations, including a base 5 and a guide rod 1, the base 5 is fixed on the ground, the upper end of the guide rod 1 is placed on the vibration-isolated object, and the base 5 is fixedly connected A concave pallet 4, a bottom plate 6 is fixed on the concave pallet 4, a door-shaped frame 3 is fixed on the bottom plate 6, a linear bearing 2 is fixedly installed in the center of the top beam of the door-shaped frame 3; the guide rod 1 passes through The linear bearing 2 is supported and movably inserted in the door-shaped frame 3, a movable hinge seat 9 is slipped in the middle of the guide rod 1, and a vertical stiffness-damping mechanism 7 is installed between the lower end of the guide rod 1 and the bottom plate 6. Both sides of the seat 9 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com