Hole arrangement fine adjustment method based on RTK blast hole positioning technology and used for improving blasting effect

A positioning technology and blast hole technology, which is applied in the field of fine-tuning of hole arrangement based on RTK blast hole positioning technology to improve blasting effect, can solve the problems of leakage of explosive energy, poor blasting effect, and accidents, etc., so as to improve perforation speed and success. The effect of improving porosity, blasting quality and reducing blasting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

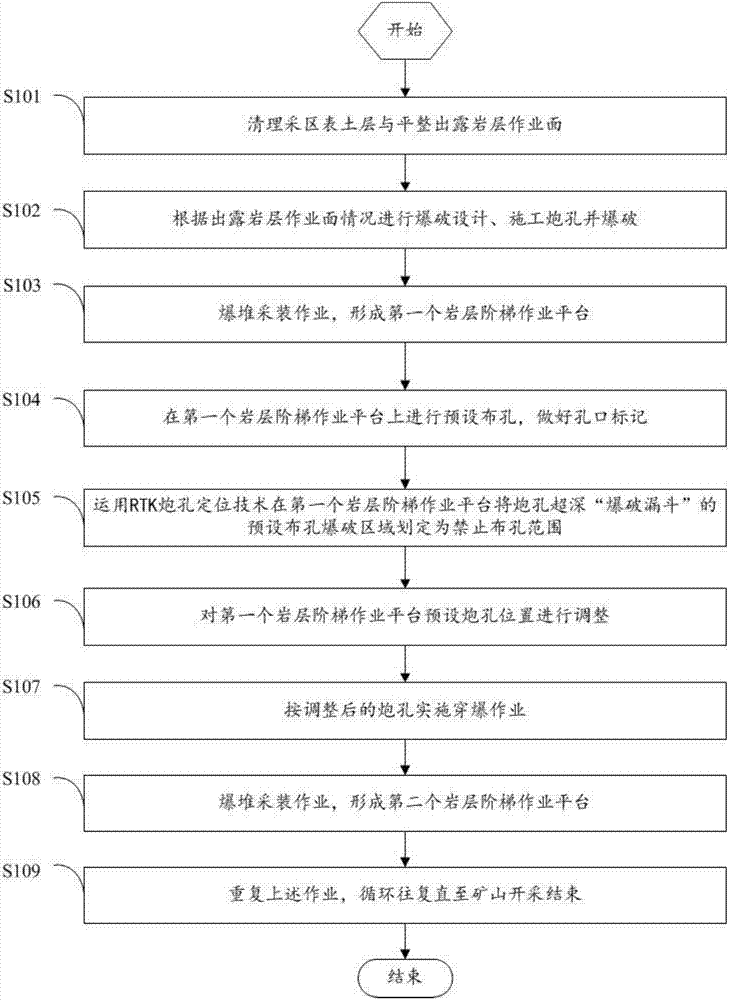

[0033] A hole layout fine-tuning method based on RTK blast hole positioning technology to improve the blasting effect, with the help of RTK through the ground base station to send differential information for receiving and solving the difference, to quickly obtain accurate positioning results, including the following steps:

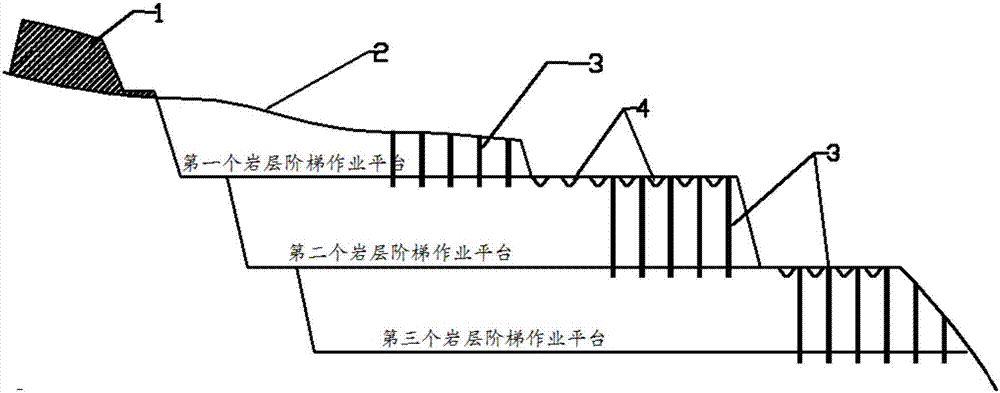

[0034] S101: cleaning the surface soil layer 1 in the mining area and leveling the working surface 2 of the exposed rock layer;

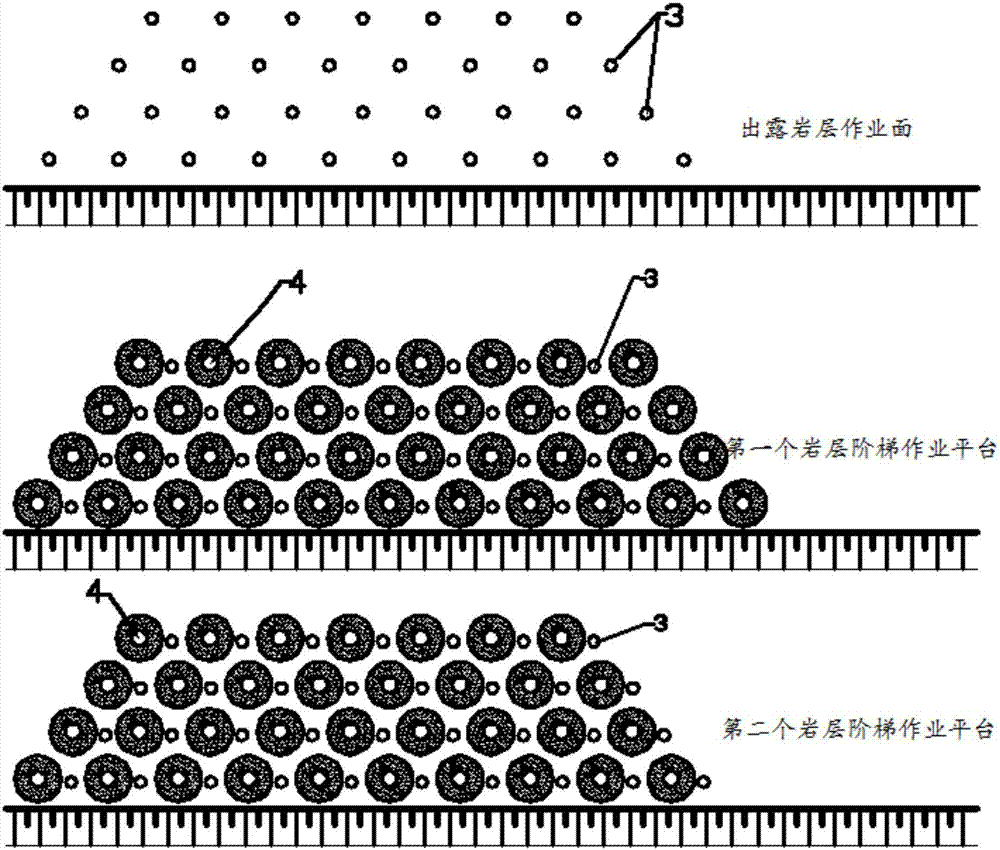

[0035] S102: Carry out blasting design, construction of blast hole 3 and blasting according to the conditions of the exposed rock formation working surface;

[0036] S103: Explosive stack mining operation, forming the first rock formation ladder operation platform;

[0037] S104: Carry out preset hole layout on the first rock formation ladder operation platform, and make hole marks;

[0038] S105: Use RTK blasthole positioning technology to delineate the preset blasting area of the ultra-deep blast hole "blasting funnel" 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com