Blasting excavation method for side slope rock mass with deep fissures

A technology for fissures and rock mass, which is applied in the field of blasting and excavation of rock mass on slopes with deep fissures, can solve the problems of narrow space, difficult to ensure the filling effect of small fissures, inconvenient construction and operation, etc. The effect of avoiding explosion-rejection accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0020] In conjunction with the accompanying drawings.

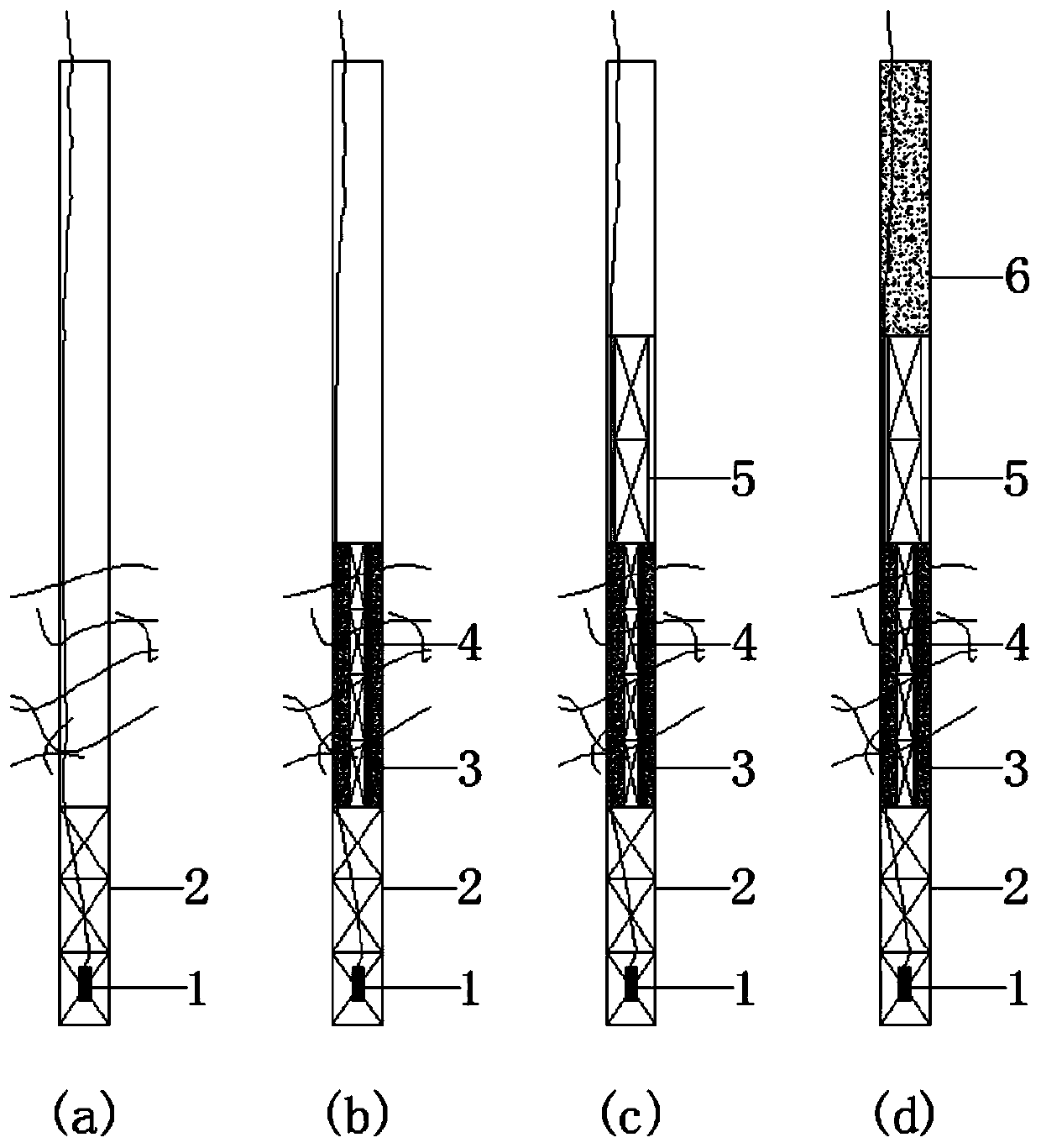

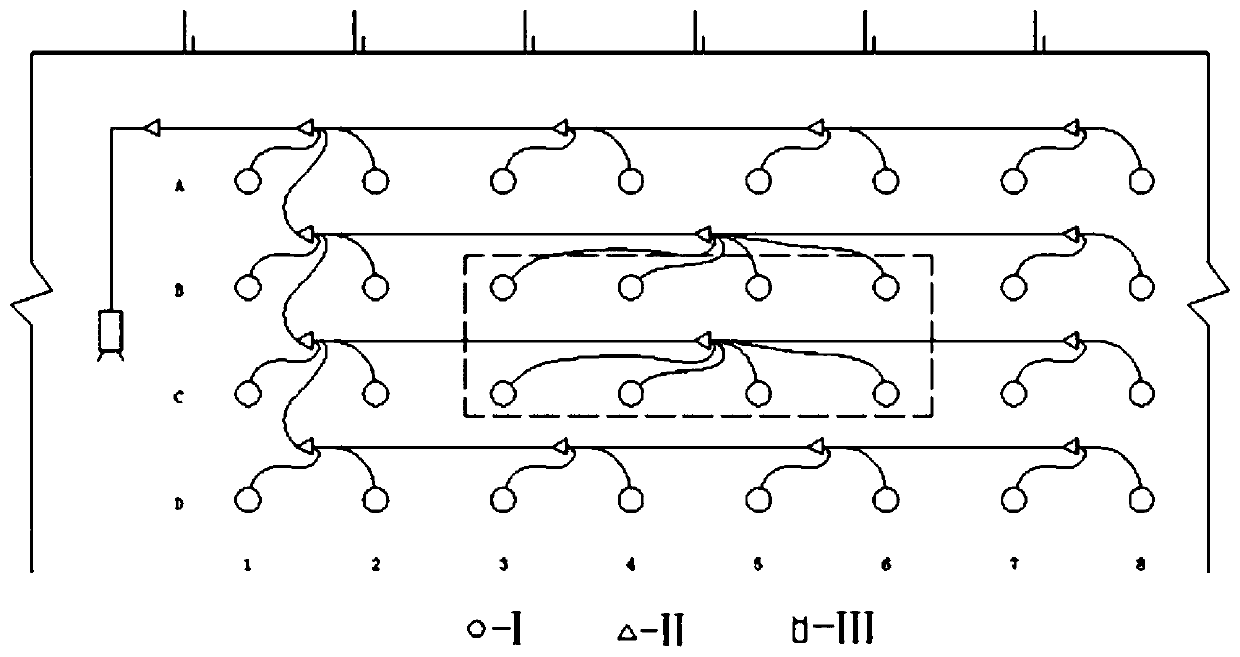

[0021] An open-pit stonework blasting adopts the deep hole step blasting method, the step height is 8.0m, the super depth is 0.8m, the drilling inclination angle is 90°, the blasthole depth is 8.8m, the blasthole diameter is 90mm, the holes are arranged in a rectangular shape, and the blastholes are divided into 4 Each row has 8 rows, and the distance between rows is 3.0×2.5m. The explosive uses No. 2 rock emulsion explosive. The length is 6.3m, and the length of the blocking section is 2.5m. The specific implementation steps are as follows:

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com