Condensed water sampling method and device for condenser leakage detection

A technology of sampling device and condenser, which is applied in the direction of sampling device, etc., can solve the problems of poor sampling representativeness and no water extraction, and achieve the effect of small flow, small system resistance and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

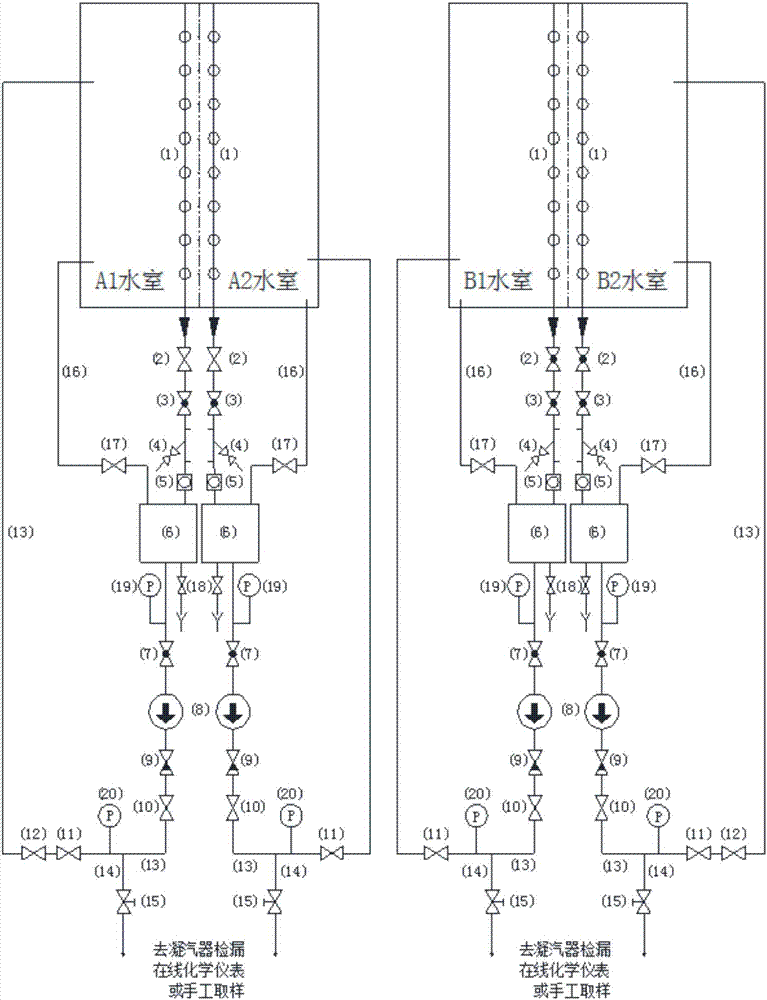

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

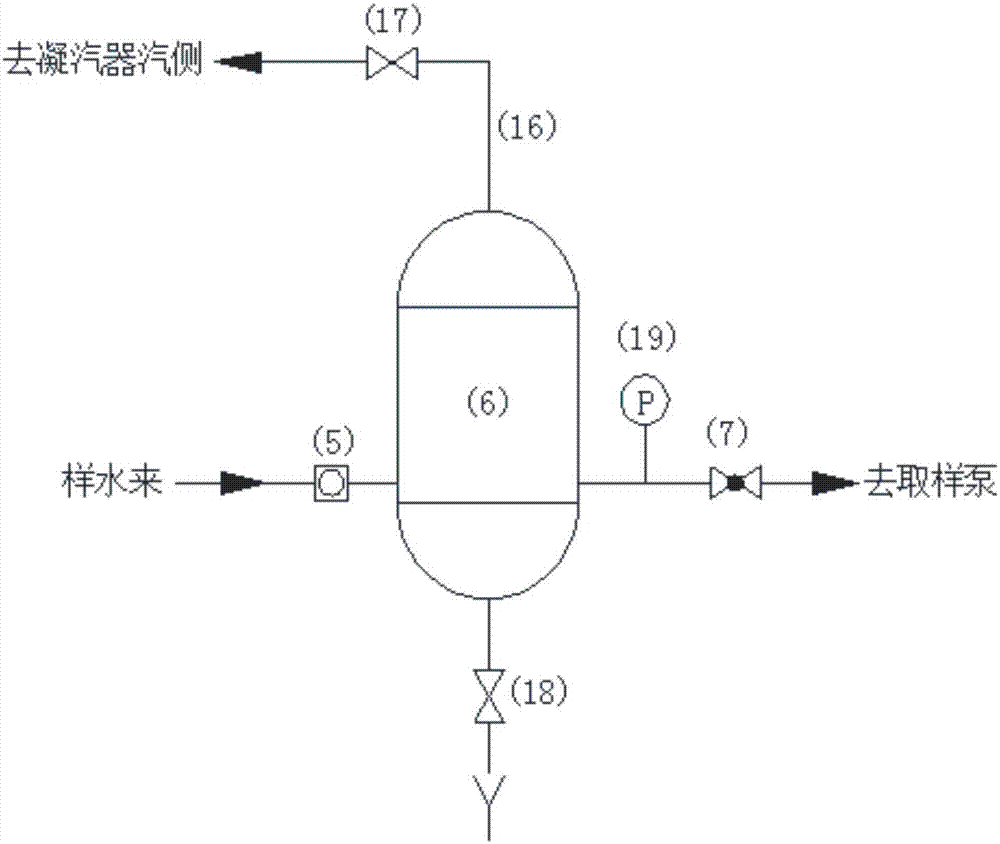

[0024] Preparations before starting: see attached figure 1 , Before starting the sampling system, check and confirm that all valves are closed. Then, open the sampling primary door 2, the sampling secondary door 3 and the exhaust valve 17 on the top of the water inlet tank 6, carry out water injection and exhaust in the sampling system pipeline, observe the indication state of the flow monitor 5, when the flow monitor indicates that the water sample After no flow, it shows that the pipeline in front of the sampling pump 8 has been filled with water and the gas has been exhausted. Close the exhaust valve 17 at the top of the water inlet tank 6 .

[0025] Operation steps: see attached figure 1 After the water injection and exhaust work, open the pump inlet valve 7, the return water regulating valve 11, and the return water valve 12, start the sampling pump 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com