Mining lead-acid storage battery high-frequency intelligent rapid-charging charger

A lead-acid battery, high-frequency technology, applied in the direction of battery circuit devices, collectors, electric vehicles, etc., can solve the problems of heavy flameproof shell, damage to the battery, overheating of the battery, etc., to improve the flameproof performance and use safety performance , prolong the service life and use efficiency, and avoid the waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

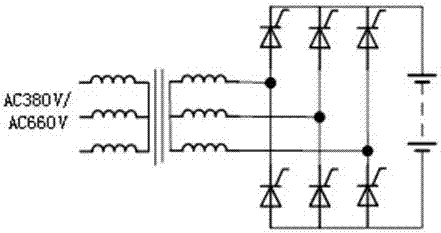

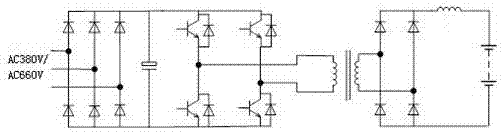

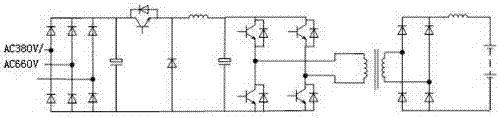

[0025] Such as Figure 4 As shown, a mine-used lead-acid battery high-frequency intelligent fast charging charger includes a general control system, a first control system, a second control system, a third control system, a PWM rectifier, a bidirectional DC / DC converter, a bidirectional H-bridge inverter I, bidirectional H-bridge inverter II and high-frequency transformer, the overall control system is connected to the first control system, the second control system and the third control system respectively through the field bus, the first The control system is connected to the PWM rectifier, the second control system is connected to the bidirectional DC / DC converter, the third control system is connected to the bidirectional H-bridge inverter I and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap