Heading and thread rolling integrated screw production equipment and screw production method thereof

A technology for the production of equipment and screws, which is applied in the direction of metal processing equipment, bolts, threaded fasteners, etc., can solve the problem that the screws cannot be completed at one time, and achieve the effects of reducing transmission steps, speeding up production efficiency, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

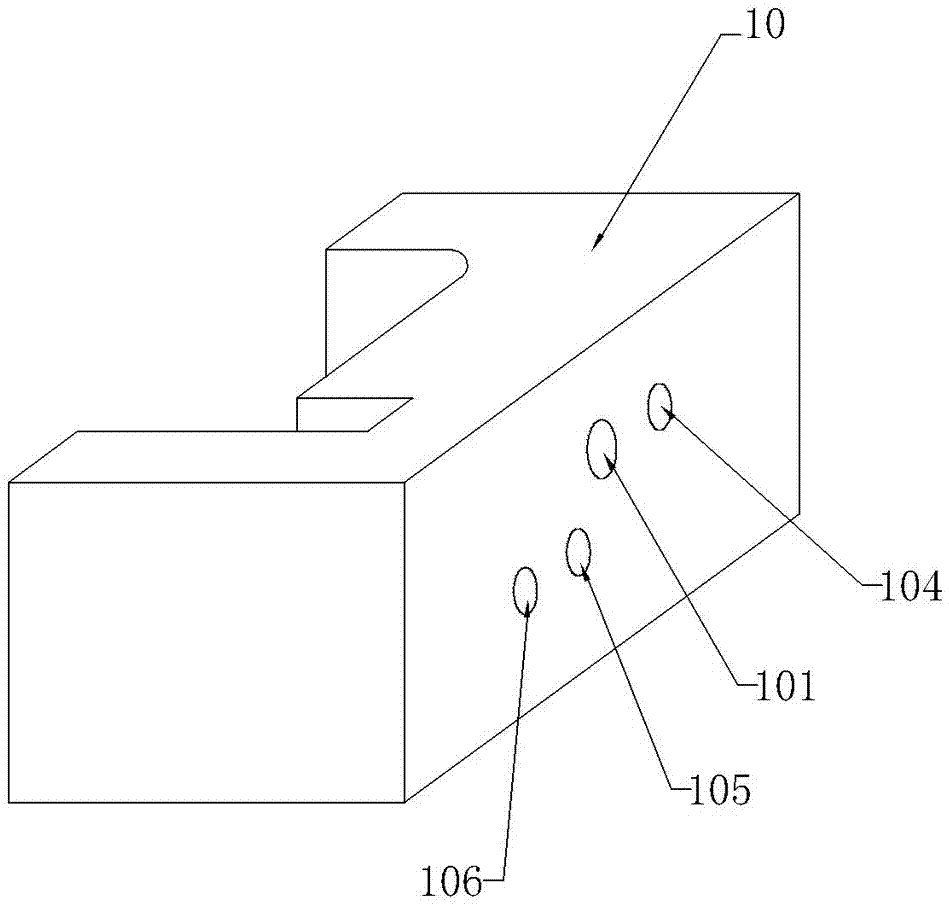

[0054] refer to Figure 1-3 , the present invention is a kind of screw production equipment integrating head and tooth rubbing, comprising

[0055] After the wire is cut, it is sent to the cutting assembly (not shown) in the female mold assembly 10;

[0056] The female mold assembly 10 that accommodates the wire to be processed is convenient for the male mold assembly 11 to process the wire;

[0057] A male mold assembly 11 for head-heading the wire to be processed;

[0058] And rubbing the outer surface of the blank to make the blank form an external threaded roller assembly 12;

[0059] The female mold assembly 10 is provided with a main mold withdrawal hole 101, a thimble 102 and a buffer hole 103; the male mold assembly 11 includes an upper die 111 for preliminary molding of the wire head and a lower punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com