Pneumatic Tantalum Core Pressing Equipment Based on Ultrasonic Antifriction Effect

An ultrasonic anti-friction and pneumatic technology, which is applied in the field of electronic components manufacturing, can solve problems such as uneven distribution of pressing density, complex structure of pressing devices, and high cost of manpower and material resources, and achieve excellent pressing effect, simple structure, and solve processing problems complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

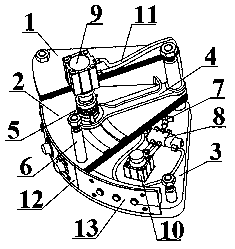

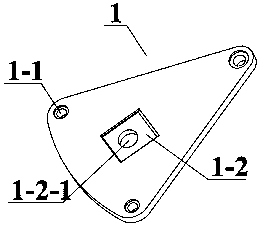

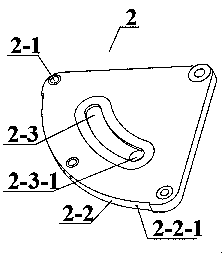

[0038] Specific implementation mode one: combine Figure 1~Figure 24 This embodiment will be described. This embodiment provides a specific implementation of the pneumatic tantalum core pressing equipment based on the ultrasonic friction reduction effect. The pneumatic tantalum core pressing equipment based on the ultrasonic anti-friction effect consists of an upper fixed plate 1, a middle fixed plate 2, a lower fixed plate 3, a rotating arm 4, a mold 5, a fixed assembly 6, a three-way joint 7, and an electromagnetic reversing valve. 8. The upper pressing cylinder 9, the lower pressing cylinder 10, the air pipe 11, the piezoelectric element control panel 12 and the pneumatic control panel 13; , to realize the fixing of the overall frame of the pressing device; the rotating arm 4 is fixed on the middle fixing plate 2 through the screw rod 6-2 and the long fixing sleeve 6-3 in the fixing assembly 6, so as to realize the fixing of the rotating arm 4 and the fixing assembly 6 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com