Multifunctional on-line monitoring pretreatment device for tailing slurry

A pretreatment device and multi-functional technology, applied in the field of online monitoring pretreatment device, can solve problems such as inability to achieve reliability and stability, and achieve the effects of easy installation and management, large filter area, and increased service cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

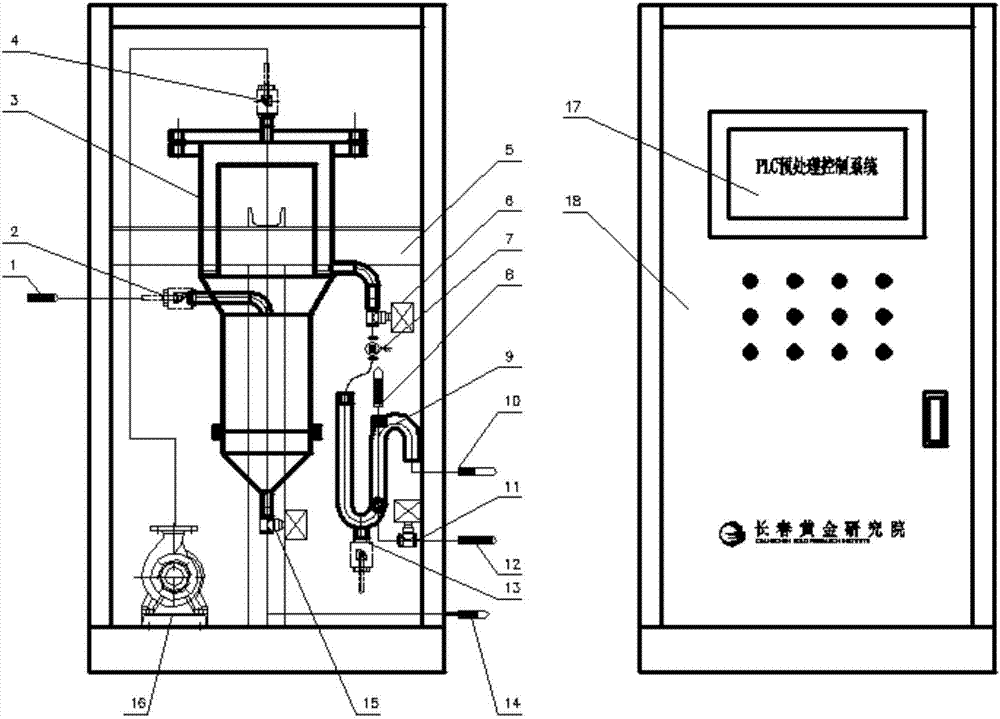

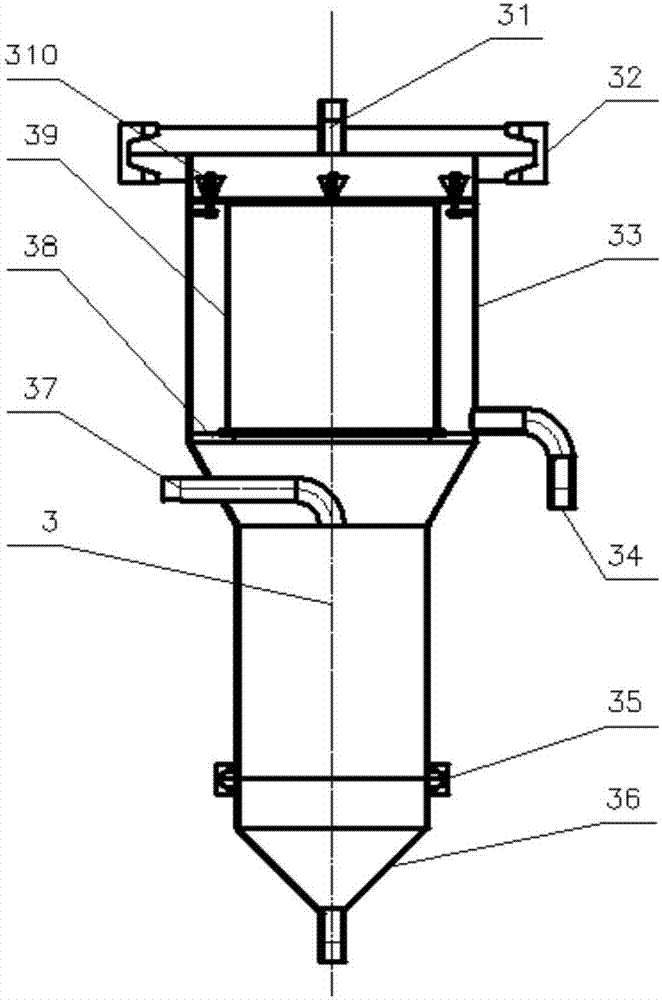

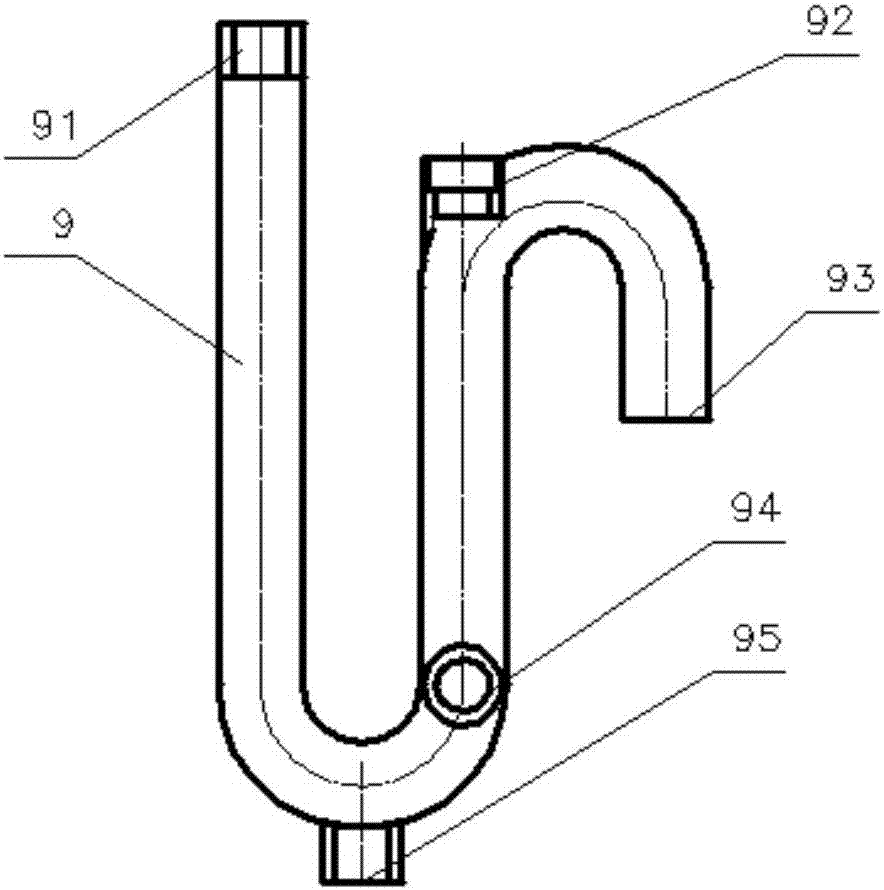

[0016] Such as figure 1 , figure 2 , image 3 As shown, a multifunctional tailings slurry on-line monitoring pretreatment device is composed of a slurry inlet pump 1, a slurry inlet valve 2, a solid-liquid separator 3, a clean water valve 4, an internal support structure 5, an electric control switch valve for outlet water 6, a flow rate Meter 7, PH detector 8, U-shaped liquid storage pipe 9, tail liquid recovery device 10, cyanide electric control switch valve 11, cyanide detector 12, sewage valve 13, slurry pump 14, slurry electric control switch valve 15 and the miniature clean water pump 16 are integrated with the PLC control module 17 and installed inside the electrical control cabinet 18 to form a filter press type solid-liquid separation on-line continuous detection system. The solid-liquid separator 3, the U-shaped liquid storage pipe 9, and the miniature clean water pump 16 are arranged on the internal support structure 5 of the electrical control cabinet 18; the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com